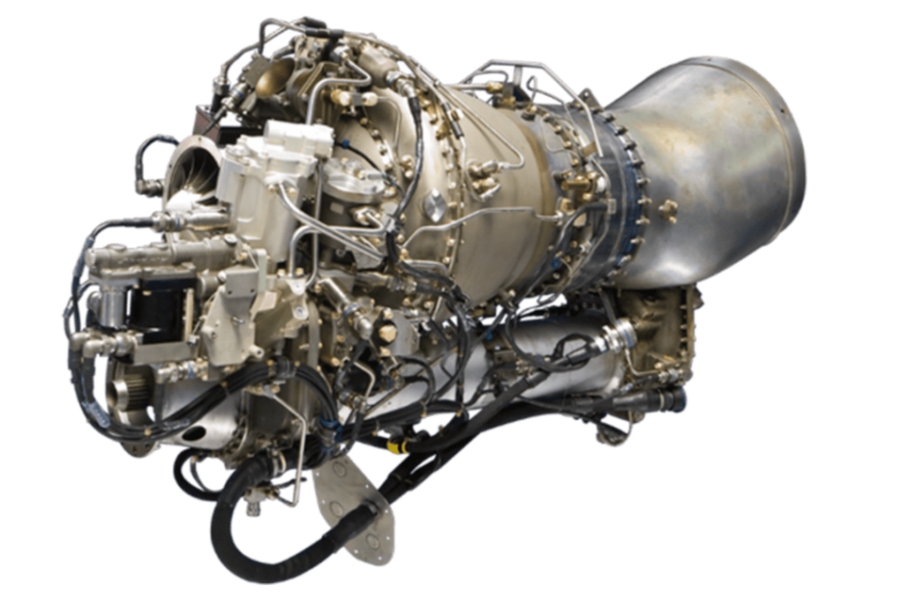

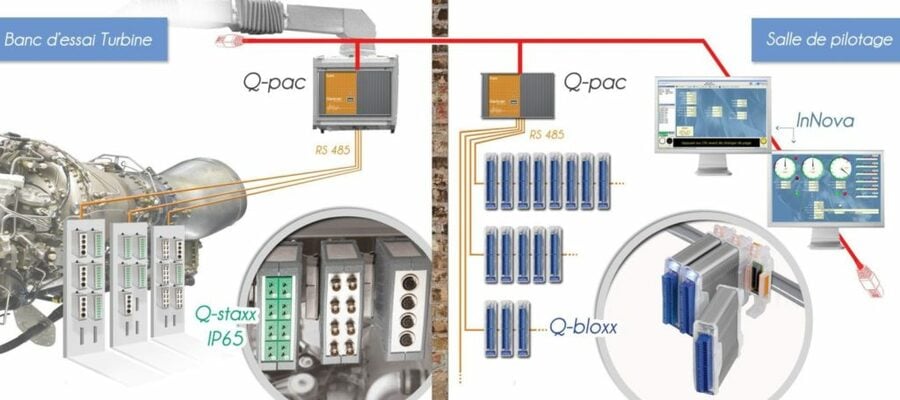

All turbines are tested for their mechanical and thermodynamic behavior.

The main requirements for this type of testing are:

- Acquisition of hundreds of measurement channels in the kHz range

- Galvanic isolation up to 1200 V

- Signal Conditioning

- Robustness and modularity

- Synchronized recording of all channels

- Measurement system can be synchronized to an external time reference

(NTP or IRIG)

More articles

The Battery Show Europe 2026

Curious about Gantner Instruments' latest innovations? Dive into our battery testing blog and discover what we have in store for The Battery Show Europe 2026!

Read more...Gantner Instruments Sponsors STEM Education

The world is changing around us. Advances in technology impact everything, especially the world of work. It’s predicted that future workers will spend more than twice as much time on job tasks requiring science, math, and critical thinking than today. At Gantner Instruments, we recognize the importance of STEM education: it holds the keys to success for kids facing a world where STEM knowledge is imperative. For that reason, we are proud to be a Platinum Sponsor of Students for the Exploration and Development of Space at the University of California, San Diego (SEDS UCSD).

Read more...GDevCon 4 Glasgow

Immerse yourself in the vibrant world of graphical programming at GDevCon 2023 on the 20th and 21st of September, from 9:00 am - 6:00 pm, at the esteemed Glasgow Science Centre, Scotland. This conference is a must-attend event for anyone striving to push the boundaries in the fields of engineering and technology.

Read more...Enhanced Functionality with GI.bench’s Newest Release: Revamped UI, Powerful Tools and More!

Introducing the latest update to our powerful and intuitive testing and measurement software - GI.bench. This update promises to elevate your testing capabilities with features designed to streamline your workflow and maximize productivity.

Read more...