Electric Vehicle &

Battery Testing

Few areas in the world of clean energy are more dynamic than the electric vehicle (EV) market. The market is growing remarkably fast as targets for CO2 emissions play an essential role in the ongoing global low-carbon transition. However, despite the many technological advancements, there are still significant obstacles to overcome regarding reliability, range, and usability. From a testing and certification perspective, EVs bring together two previously separate worlds at Gantner Instruments, automotive and renewable energy, resulting in an industry-leading data acquisition solution for testing battery packs, inverters, and electric motors.

Gantner Instruments is dedicated to helping our customers accelerate the development of battery-electric, hybrid-electric, and fuel-cell vehicles.

Dynamometer testing to determine an electric motor’s speed, torque, and power characteristics for performance, durability, in-use simulation, and end-of-line quality control.

Full vehicle testing on a chassis dynamometer for establishing electric energy consumption metrics and benchmarking the effectiveness of the vehicle’s powertrain under numerous testing conditions and environments.

Battery testing for verifying durability, safety, and reliability; Tests are performed under high-voltage conditions, like thermal abuse, mechanical penetration, environmental, charge, discharge, and lifecycle testing.

Testing inverters at different operating conditions and various DC and AC boundary conditions to perform power measurement and analysis, like real power, apparent power, power factor, and efficiency.

Performance and benchmark testing of fuel cell electric vehicle (FCEV) powertrains, addressing gas flow, humidification, temperature, pressure, and behavior under stress.

MHz DAQ and Power Analysis for EV & Battery Testing

In the fast-evolving world of electric vehicles (EVs) and battery technologies, MHz data acquisition (DAQ) systems and power analyzers are crucial.

- MHz DAQ

Ensures precise measurements of voltage and current signals, capturing intricate system behavior details for improved performance and reliability. - Noise Performance

A low-noise floor is key to accurate power analysis, enabling informed decision-making and system design improvements. - Harmonic Distortion

Monitoring total harmonic distortion (THD) enhances system performance, extends system lifespan, and reduces maintenance costs. - Power Analysis

Comprehensive power analysis features provide a holistic performance assessment, leading to system design optimization and high safety levels.

Optimizing your EV and battery testing requires the integration of MHz DAQ and advanced power analysis. Ensure these are part of your toolkit to drive the future of EV and battery technology.

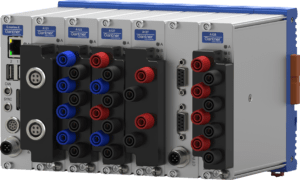

Q.boost Power Analyzer delivers unmatched high-speed performance for all E-drive applications. With a speed of 4 MHz at 24-bit resolution and a bandwidth of 1.7 MHz, it sets a new standard for powertrain testing.

Our Power Analyzer features outstanding signal conditioning capabilities for utmost accuracy in power calculations. It achieves less than 3 ppm distortion and less than -140 dB noise-floor, ensuring precision and reliability in every measure.

The Q.boost Power Analyzer offers a wide array of inputs to accommodate all your testing needs. It includes 4+4 channels for voltage and current, input ranges from +-500 mV to +-1500 V, galvanic isolation of all channels, a built-in bipolar power supply system for easy connection of current transducers, and pulse/counter inputs for torque and speed sensors.

4. Our power analyzer is designed for seamless integration into your existing systems. It offers an open API, a CAN interface for transferring results with Q.core, and an upcoming EtherCAT interface. It’s also compatible with the Q.series X DAQ platform, facilitating a smooth upgrade process. The Q.boost Power Analyzer is available for current measurement with shunts or voltage output transducers, allows 6-phase measurement with a second unit, and can be conveniently installed in a 19″ rack.

With the Q.boost Power Analyzer, you get powerful data analysis capabilities. It provides continuous online calculation of power, power factor, total harmonic distortion (THD), and more with GI.bench on your PC or PC-independent with Q.core. Moreover, it allows real-time access to all high-speed raw signals, enabling immediate insights and decision-making.

Electrical, Thermal, and Mechanical Evaluation of Batteries

Testing solutions for all development and qualification steps:

- Charge/discharge cycle testing – Determine the number of times a battery can be used by evaluating it until it deteriorates after repeated charging and discharging charges.

- Battery Model development – SoC, SoH determination and prediction, constant discharge testing, Charge/Discharge rate, and efficiency

- Safety (abuse) testing – Simulate a wide range of environmental conditions and battery failure scenarios to determine the conditions for battery failure.

- Performance testing – Demonstrate the efficiency of batteries. Our experts can customize testing programs to suit specific customer requirements, such as performance testing under various climatic conditions.

- Environmental and thermal testing – Demonstrate the quality and reliability of your battery. Our tests include vibration, shock, EMC, thermal cycling, corrosion, dust, salt, and humidity.

- Transport testing – Ensure batteries can be transported safely. We conduct tests for the United Nations requirements (UN 38.3) for the safe transportation of batteries, modules, and cells.

Why Gantner Instruments

Flexible Mixed-Signal Data Acquisition

The Q.series X is a mixed-signal, multi-channel data acquisition solution offering a versatile range of I/O modules. You can measure voltage, current, temperature, torque, strain, vibration, counters, and more. With this maximum sensor flexibility, the DAQ system can be easily adapted to the demanding requirements of EV powertrain testing.

1500V High-Voltage Galvanic Isolation

Q.series X high-voltage isolation measurement modules are suitable for voltage, current, RTD, thermocouple, IEPE, and strain gage sensors sampling up to 100 kHz. All high-voltage isolation modules include a minimum of 1500 VDC channel-to-channel, channel-to-supply, and channel-to-bus galvanic isolation.

High-Accuracy Thermocouple Measurement

Temperature is a key measurement for improving battery and overall electric powertrain efficiency. Clever input circuits and high-voltage galvanic isolation ensure the highest accuracy in any test environment.

Fully Configurable Data Loggers

Engine testing generates a lot of data with varying sample rates. Mixed-signal, multi-frequency data logging ensures only the data you need is saved, avoiding unnecessary data storage overhead.

Easy Integration

Easy-to-use APIs, modern publish-subscribe protocols, and various Fieldbus interfaces, like CAN, EtherCAT, and PROFINET, make it simple and easy to integrate the Q.series X into any supervisory control and data acquisition system. Plugins & drivers for LabVIEW, MATLAB, and Python, among others, enable advanced data analysis and reporting.

Share dashboards across networks

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.

AE

Measuring temperature in components of Hybrid Electric Drives

Click here to request

access to every

GI Application Example

Who trusts Gantner for Electric Powertrain Testing?