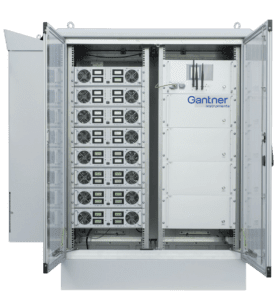

Outdoor Test Facility (OTF)

for PV Module Performance Testing

Outdoor PV Module Testing – Why is testing essential?

It is crucial to have a proven understanding of each PV Module technology’s measured outdoor performance to maximize the energy output through optimized PV Module and system design.

Measured PV module performance over time determines the quality, energy yield, and costs.

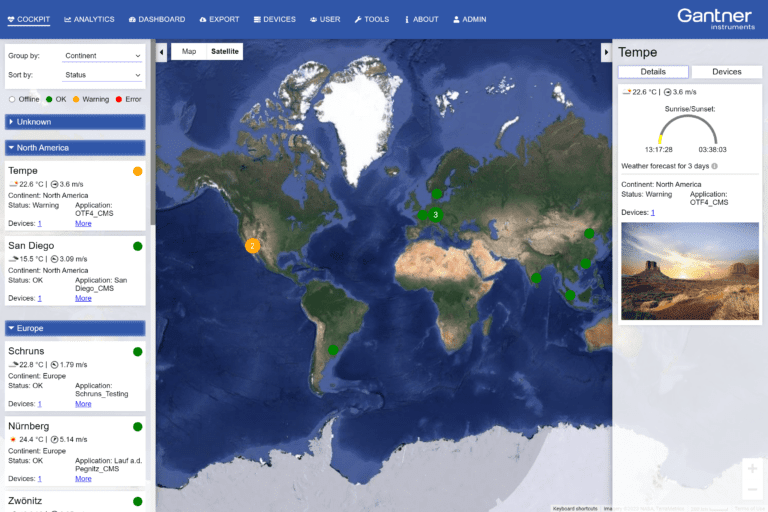

The Outdoor Test Facility from Gantner Instruments provides all this data for easy and accurate technology comparison and validation. This tool allows measurements of long-term track records, energy yield, bi-facial gain, low light behavior, and thermal coefficients of different PV Modules to support bankability.

Who stands to gain from the Outdoor Test Facility data?

Understanding and verifying real PV Module behavior is vital for various stakeholders. These include PV module manufacturers, system integrators, insurance firms, financial institutions, investors, and R&D departments keen on comprehending technology behavior’s intricacies.

For PV Technology Developers:

- Enjoy seamless energy yield comparisons and analysis with our integrated, one-click analysis methods.

- Showcase the benchmarking and evolution of your technology effectively.

For those conducting Site Assessment/Prospecting:

- Our weather and PV data are perfect input for all stakeholders along the PV value chain, enhancing your site assessment efforts.

For those seeking Risk Reduction for Insurance:

- Benefit from reduced risks and quicker detection of losses through our high-quality weather and performance data. This data is useful in project development, technology decisions, system requirements, performance simulations, and devising O&M strategies and controls.

For Digital Twin Developers:

- Utilize our facility as a reference data source for your digital twin development and advanced grid integration modeling.

For O&M Providers:

- Take advantage of high-quality PV module data to keep 66% of all Levelized Cost of Energy (LCoE) cost drivers under control.

- Qualify optimized O&M concepts for large plants and real-time performance prediction, including dust impact and cleaning strategies.

For those involved in Grid Integration and Prediction:

- Achieve real-time performance prediction with better accuracy than your irradiation sensors: ±2.5% accuracy (nRMSE) on large-scale plants, enhancing your grid integration efforts.

Features of the Outdoor Test Facility:

- User-friendly analysis tools for effortless data interpretation

- Seamless PV Module installation with a plug & play design

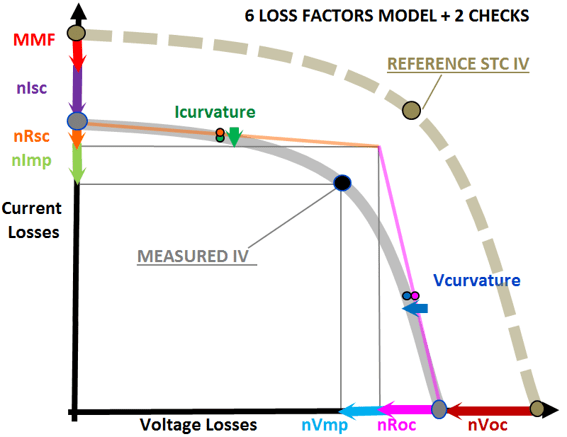

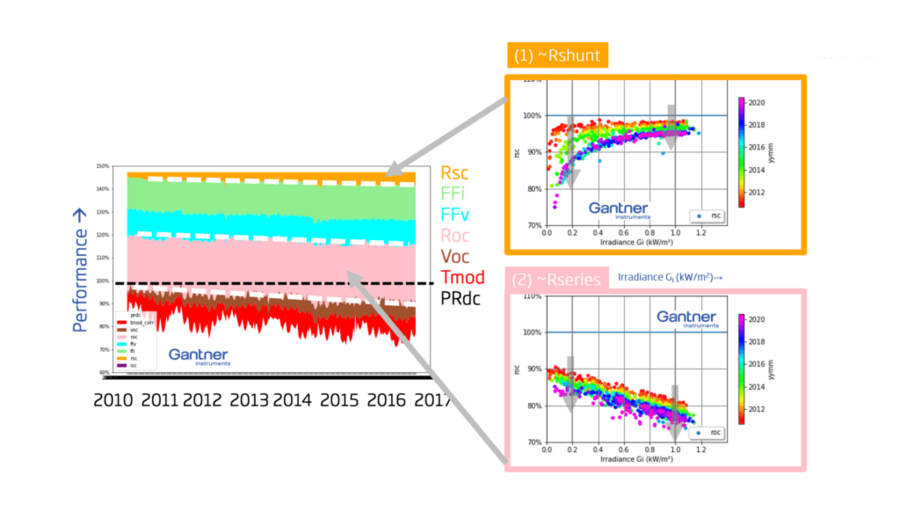

- Incorporating a Loss Factors Model (LFM) can effectively determine a module’s performance and is achieved through its I-V curve, factoring in six physically significant and independent normalized “loss factors” and spectral and temperature adjustments for precise results.

How can this service benefit your business?

- Offers pre-configured measurement settings for various PV technologies, such as thin film, crystalline technologies, and flexible substrates, facilitating technology benchmarking and analysis.

- Provides easy validation of expected energy yield, low light behavior, long-term stability, and temperature coefficients, with the support of advanced methods including the Loss Factor Model.

- Delivers data that forms a robust basis for informed investment and technology decisions.

- Enables the understanding and measurement of actual module behavior in varied locations and under different environmental conditions, validates long-term behavior, and substantiates bankability.

Dynamometer testing to determine an electric motor’s speed, torque, and power characteristics for performance, durability, in-use simulation, and end-of-line quality control.

Full vehicle testing on a chassis dynamometer for establishing electric energy consumption metrics and benchmarking the effectiveness of the vehicle’s powertrain under numerous testing conditions and environments.

Battery testing for verifying durability, safety, and reliability; Tests are performed under high-voltage conditions, like thermal abuse, mechanical penetration, environmental, charge, discharge, and lifecycle testing.

Testing inverters at different operating conditions and various DC and AC boundary conditions to perform power measurement and analysis, like real power, apparent power, power factor, and efficiency.

Performance and benchmark testing of fuel cell electric vehicle (FCEV) powertrains, addressing gas flow, humidification, temperature, pressure, and behavior under stress.

Unlock the Full Potential of Your PV Module

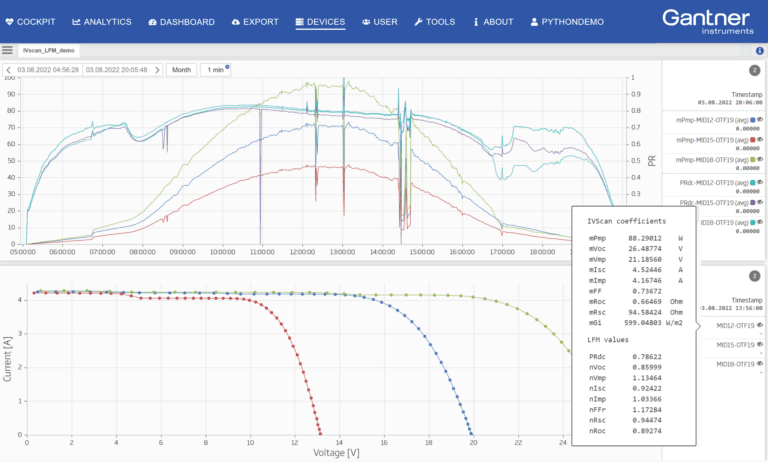

The IV curve, a depiction of the relationship between a PV Module’s output voltage and current, offers crucial insights into the module’s performance. In an ideal world, it’s a straight line up to a certain point before curving and plateauing at the maximum power point (MPP) – the juncture where the product of current (I) and voltage (V) peaks, thus maximizing energy production from your solar module.

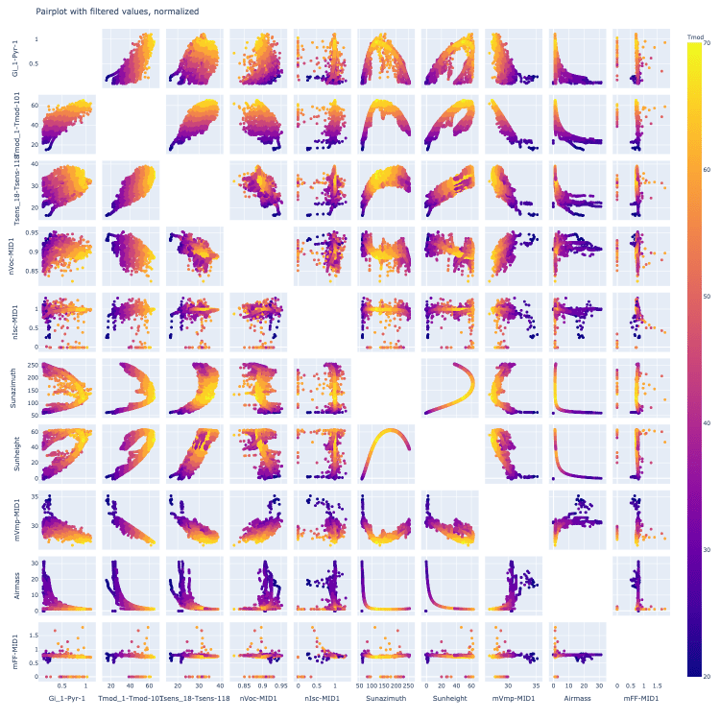

Observing the curve from short circuit (Isc) to open circuit voltage (Voc) at varying outdoor irradiances and temperatures gives you real-world insights into the module’s material, degradation, faults, shading, and rated power.

Over time, IV scans chronicle a module’s life stages – early, middle, late – each with unique faults. These faults, if unaddressed, are the primary factors that affect a PV plant’s energy yield. This knowledge lets you detect, address, and enhance your PV module’s performance.

What is a PV Outdoor Test Facility?

Looking to understand what a PV Outdoor Test Facility (OTF) is? It’s a versatile platform that concurrently measures electrical and meteorological parameters, accurately characterizing any PV technology in real-world conditions. The OTF specializes in drawing precise IV curves, performing real-time extraction, and normalizing all parameter values. It easily handles high-power PV Modules over 650Wp, hetero-junction, and bi-facial technologies.

The OTF offers repeated measurements over time, effectively pinpointing and quantifying performance degradation, losses, or seasonal shifts. All captured parameters are primed for visualization, post-processing, or reporting to stakeholders. For advanced analysis, you can harness the power of the integrated Python Jupyter Lab platform or utilize the open API for machine learning applications.

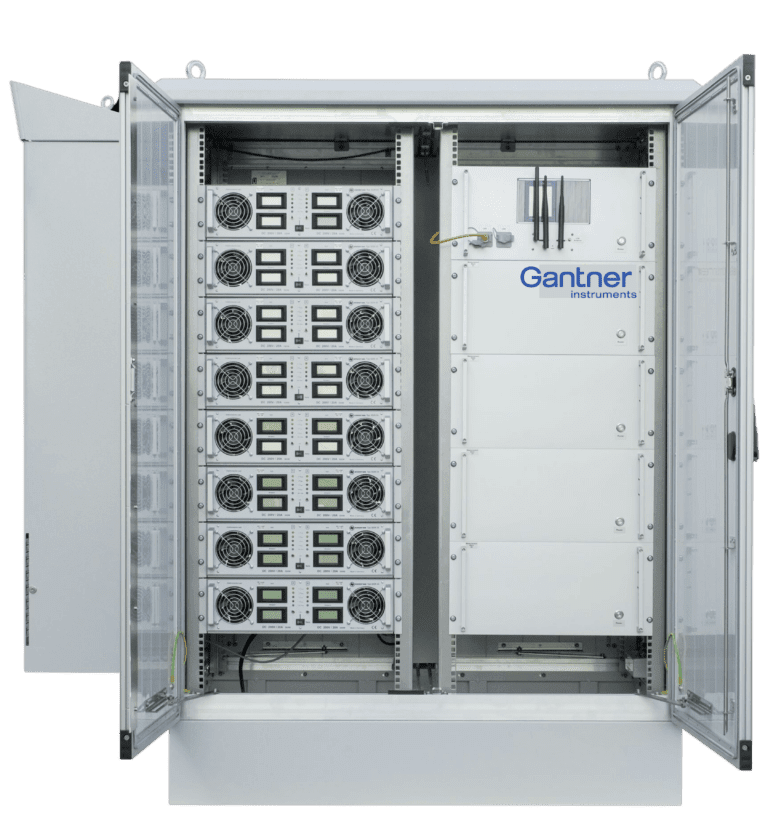

Data Acquisition System

- Plug-and-play PV module setup supporting up to 800W power measurement.

- High-resolution IV curve measurements.

- Single measurement channel per module/string for maximum data accuracy.

- Comprehensive environmental sensor setup: captures irradiation, weather, module temperature data.

- Synchronized data acquisition with automatic KPI computations and MPP tracking.

- Flexible IVscan parameters featuring built-in self-calibration.

- Compatible with Modbus and OPC-UA interfaces.

- Customizable configurations for both indoor/outdoor and offgrid/grid-connected setups.

Automated Data Enrichment

- Real-time data processing and on-the-fly parameter calculations

- Instant data normalization and weighting

- Metadata per PV module testing cycle, such as STC reference values, datasheet information, etc

- Loss Factor Model (LFM) integration for advanced IVscan analysis*

- Remote access and configuration

*LFM (Loss Factors Model) Service: An exclusive service that gauges a module’s performance using its I-V curve. It calculates performance as the product of six independent, normalized “loss factors” with spectral and temperature adjustments.

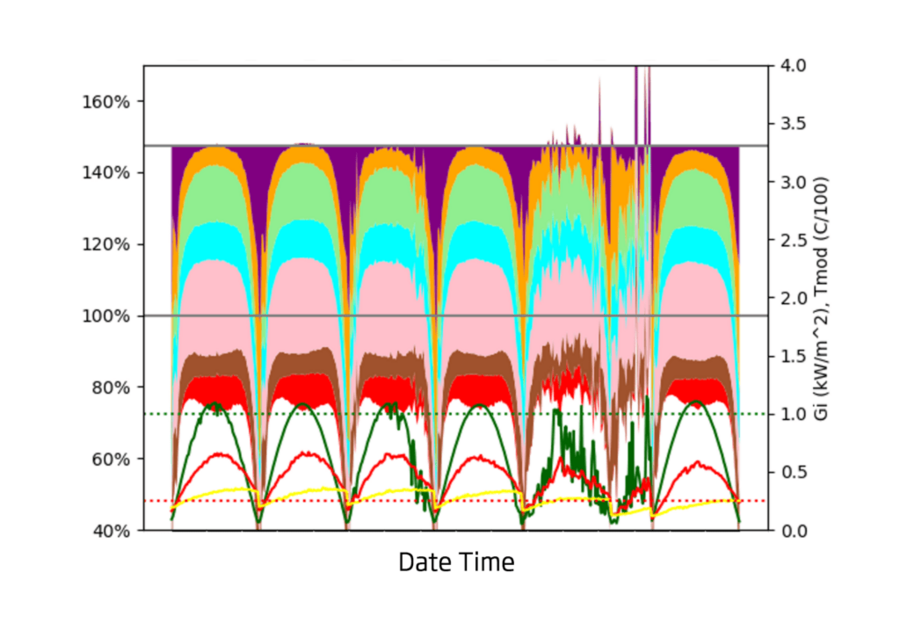

What Insights can Customers Gain with our Analysis?

- Core Energy Yield Metrics: DC performance ratio (PRdc), annual energy yield (YA), reference yield (YR), yearly sun hours, etc.

- PV Module Performance: Daily, monthly, and yearly evaluations

- Technology Benchmarking: Comparisons at high and low light conditions

- Thermal Analysis: Insulation, temperature coefficients (TC), low light behavior, light-induced degradation (LID) impacts

- Bi-Facial Analysis: Gain and albedo modelling.

- Seasonal Variation Identification

- Environmental Impact: Effects of wind speed and spectral impacts on multi-junction technologies

- Tracking Strategies: Validation of various approaches

- Simulation Validation: Checks of functions (e.g., PV Syst, PV_Lib Functions) and modelling data sets like 1Diode parameters, Loss Factor Model (LFM) coefficients – applicable regardless of site

- Weather Response: Reactions to variable weather, grid integration curtailment studies.

- O&M Optimization: e.g., determining when to initiate cleaning activities

- AI Training: Algorithms for fault detection, seasonal trend detection

Why Choose Gantner for Outdoor testing?

Time-Synchronized Signals

Real-time kernel ensures microsecond synchronization.

Stability and Uptime

No multiplexing or switching with dedicated DC-load per channel.

Industry-Tested Components

Features 24-bit resolution and high galvanic isolation voltage (1500 VDC).

Superior Measurement Accuracy

Achieves 0.05% typical precision.

Unmatched Data Quality

Delivers unparalleled data quality at an unbeatable cost per IVscan channel.

Scalable System

Standalone design that scales according to your needs.

High-Quality IVscan

Best in class smoothness, e.g., normalized Resistance vs. Voltage (nRV) curves.

Industry Verified

Reviewed by Sandia, NREL, and Tier 1 PV Technology players.

Integrated Python/Jupyter Lab

Streamline your data analysis with pre-enrichment.

Who Trusts Gantner in Outdoor Testing?

With over 15 years of professional testing and analysis services worldwide, Gantner Instruments helps customers deliver faster, scalable, and more reliable results in the competitive PV market.