Aerospace

Structural

Testing

Why Gantner Instruments

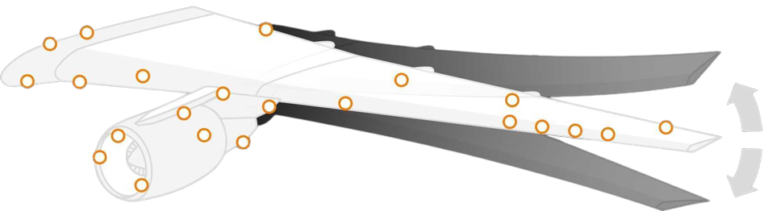

High Strain Gage Measurement Certainty

For structural testing of aircraft components, strain is the single most important measurement. Q.series X strain gage modules come with a high-stability bridge completion resistor for quarter-bridge configurations and the unique Online Compensation Signal (OCS) feature for continuous lead wire resistance compensation.

Reliable, Multi-channel Data Processing

While traditional data acquisition solutions focus on handling data in batches, a streaming data architecture consumes data immediately as it is generated. Our Q.core data acquisition controller offers a scalable data backend for handling data from thousands of strain gage sensors with multi-site remote data monitoring capability for direct processing, analyzing, and reporting test data.

Multi-frequency and Redundant Data Logging

Full-scale component tests generate a lot of measurement data due to the many strain gage sensors used. The fully configurable data loggers offer maximum flexibility for generating fatigue time series data whether you prefer low-frequency continuous logging, triggered high-speed logging, snapshot logging, or peak-valley logging. Q.series X systems have multiple levels of redundancy for assured data availability.

Open Interfaces for Cost-Effective Monitoring of Complex Tests

Predicting or quickly detecting structural failures is important during a complex full-scale component test. Reliable interoperability between load control, data acquisition, and simulation systems are vital for making reporting of test results, including correlation with simulation models, more efficient. GI.connectivity provides safe and reliable data exchange and interoperability through various read/write interfaces, including collaborative solutions for test systems from Moog and MTS.

Nanosecond Time Synchronization Between All Channels

Asynchronous measurement data is one of the major uncertainties during a test program. Q.series X features out-of-the-box time synchronization between all channels. Even when the system is distributed over long distances, it ensures precise nanosecond synchronization. Various time protocols are supported to synchronize with a high-precision timekeeping device or ancillary control & measuring systems.

Who trusts Gantner for Aerospace Structural Testing?