Electrochemical Impedance Spectroscopy (EIS)

Easy-to-Integrate Multi-Channel High-Power Solution

Unlocking the Full Potential of Batteries, Fuel Cells and Electrolyzers with EIS

Electrochemical Impedance Spectroscopy (EIS) is a sophisticated diagnostic method examining the complex internal chemistries of batteries, fuel cells, and electrolyzers by measuring electrical fluctuations defining electrochemical systems’ operational health and efficiency, supporting developmental research and maintenance. EIS analyzes the dynamic responses of these systems by applying sinusoidal signals and monitoring the resultant electrical behaviors, thus revealing processes invisible to direct current evaluations. Through detailed analysis of resistance and reactance in these systems, EIS aids in preserving electrode integrity and forecasting future performance, thus minimizing risks and improving the reliability of electrochemical energy storage and generation across various applications, from small-scale laboratory tests to large industrial implementations.

GI.bench – for Modern and Robust Measurement Setups

The GI.bench software platform combines faster test setups, project configuration and handling, as well as visualization of data streams in one digital workbench.

It enables you to configure, execute and analyze your measurement and test tasks on the fly. Access live and historical measurements data anywhere.

With GI.bench’s UI design, experience the difference in accessing high-availability measurement data, anywhere. Witness the power of the new features in action with our Microphone demo.

To optimize your testing and monitoring projects, GI.bench now includes an Oscilloscope widget with sin and rectangle wave functions and new FFT Chart. Enhance your data analysis with the Statistics view in the marker window. Access historical sources from a dedicated tree and view live data with a click. These features of GI.bench enable you to configure, execute, and analyze your testing and monitoring projects more efficiently.

Benefits of Electrochemical Impedance Spectroscopy (EIS)

EIS is instrumental for stakeholders in the energy sector who are refining the operational efficiencies of electrochemical devices. This sophisticated method quantifies the electrical impedance of batteries, fuel cells, and electrolyzers. It offers insights into their electrochemical behavior crucial for improving operational efficiency and extending the lifespan without disrupting their operation. The technique’s capability to deliver high-resolution impedance measurements across a wide frequency range aids in resolving issues before they impact system performance. This proactive approach streamlines the maintenance process and significantly reduces the associated costs by targeting potential problems at their inception.

- In-depth Battery Health Insights: EIS technology offers deep insights into battery systems, enabling you to optimize performance and extend battery life.

- Non-Invasive Analysis: EIS is a non-destructive method that reveals crucial internal battery behaviors without damaging the battery, ensuring your systems remain intact while being analyzed.

- Comprehensive Impedance Breakdown: With EIS, you can distinguish between resistance and reactance in your batteries, gaining detailed knowledge of internal processes like charge transfer and ion diffusion, which are crucial for maintaining electrode integrity.

- Predictive Maintenance: EIS provides a current health status and predicts future battery performance, allowing preemptive action to prevent issues, thereby improving reliability and reducing costs.

- Cross-Application Versatility: Beyond battery optimization, EIS is invaluable for advancing electrolyzer and fuel cell technologies. By assessing the impedance characteristics of these systems, EIS provides key insights essential for enhancing performance and driving innovation in these vital energy sectors.

How EIS Works: Measurement and Data Processing Steps

EIS provides a comprehensive and non-destructive means to assess and improve the health and functionality of electrochemical systems, supporting the advancement of energy storage and conversion technologies. It delves into the microscale electrical responses induced by sinusoidal inputs, highlighting the underlying mechanisms influencing system performance and stability. Through precision measurements across a broad frequency spectrum, EIS deciphers the critical parameters that dictate the health and efficiency of these electrochemical systems.

Process

Overview

of EIS

System Preparation

Before starting the EIS measurement, the system under test—a battery, fuel cell, or electrolyzer—is meticulously prepared. Preparation includes cleaning, assembly verification, and proper connections to ensure the system interfaces correctly with the EIS instrumentation.

Frequency Selection

An appropriate frequency range is chosen based on the expected electrochemical processes within the system. EIS measurements typically span from very low frequencies, 1 milli Herz up to 10 kHz, allowing for a comprehensive analysis of slow and fast processes.

Superimposing of AC Voltage or Current

A small amplitude alternating current (AC) or voltage is superimposed to the electrochemical system. This signal is deliberately kept within the linear response range to avoid non-linear behavior, ensuring the measurements reflect the system’s inherent properties.

Measurement of Response

The system’s response to the applied AC signal is recorded over the selected frequency range. This response is typically an AC voltage or current signal that is phase-shifted and possibly attenuated compared to the applied signal. The system’s output includes the voltage or current amplitude and phase shift relative to the input signal, providing data on how the system reacts to each excitation signal frequency.

Impedance Calculation

The impedance at each frequency is precisely calculated by dividing the measured voltage response by the current response (Z = V/I). This calculation also considers the phase shift between the voltage and current, providing a complex number with both magnitude and phase components, revealing the system’s resistive and reactive characteristics.

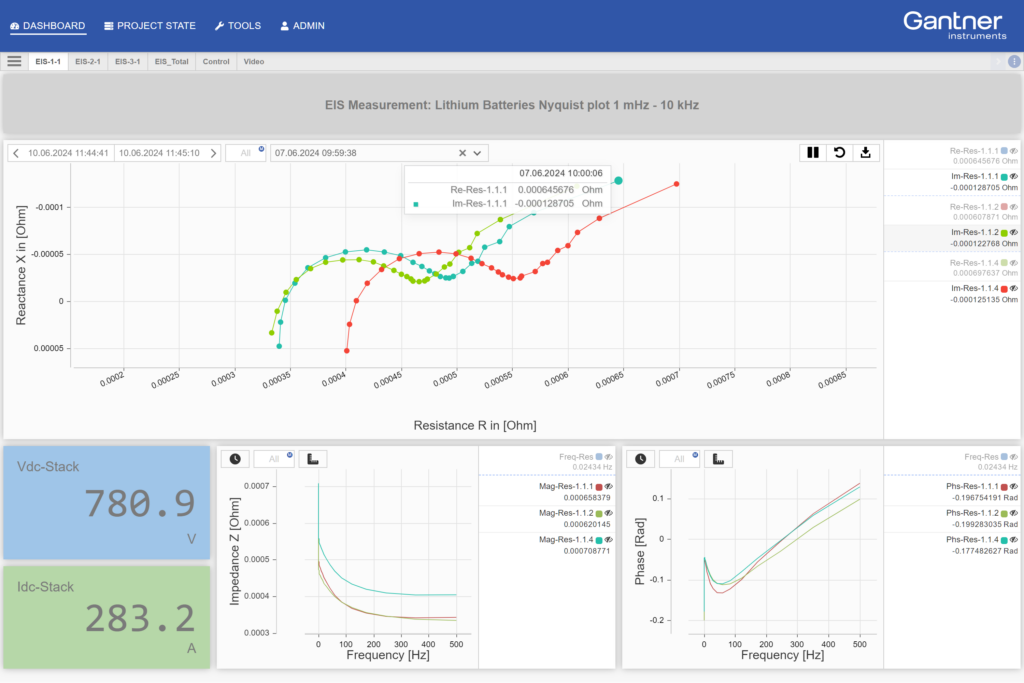

Data Visualization

The resulting impedance data is typically displayed in graphical formats such as Bode plots, which show the magnitude and phase of the impedance versus frequency, and Nyquist plots, which plot the real part against the imaginary part of the impedance. These plots interpret the system’s electrochemical behavior across the tested frequency range.

Further Analysis

After the initial data collection and plotting, further in-depth analysis is conducted, including model fitting and parameter extraction. These advanced analyses are essential for a deeper understanding of the electrochemical processes, helping to identify issues before they lead to system failure and enhancing the predictive maintenance capabilities.

EIS is your key for the qualification and

efficient operation of Batteries,

Fuel Cells, and Electrolyzer stacks.

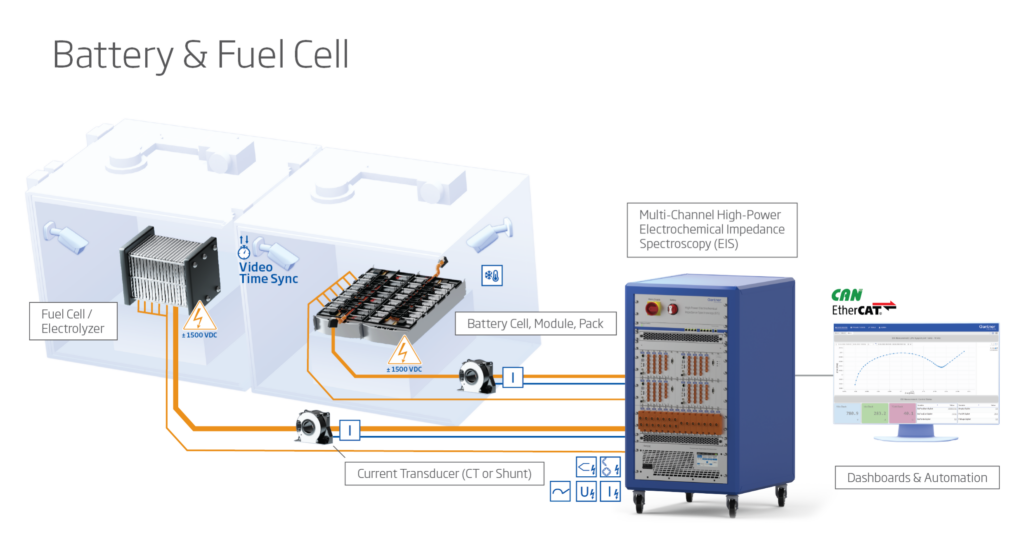

Gantner’s All-in-one EIS Solution

EIS Measurement System: Scalable and Modular

The Electrochemical Impedance Spectroscopy (EIS) measurement system comprises various critical components designed to facilitate precise and comprehensive analysis of electrochemical systems:

- Device Under Test: Depending on the application and research objectives, this typically includes batteries, fuel cells, or electrolyzers.

- Signal Generation and Modulation: This component generates accurate test signals. It controls the electrical excitation applied to the electrochemical system under test, ensuring the integrity of the EIS measurements.

- Programmable Bidirectional Power Sources: These are essential for providing adjustable test conditions. They allow researchers to simulate different operating environments for the device under test, critical for thorough and relevant EIS analysis.

- DAQ Solutions: Devices like Q.raxx A193 and Q.station capture detailed data on impedance, current, voltage, temperature, and strain. This data is vital for analyzing the electrochemical behavior and health of the system under test.

- Controller for Algorithm and Data Access: Such as the Q.core 201 EIS, this unit manages the algorithms for data processing and ensures seamless access to measurement data for further analysis.

Safely and quickly disconnect power for maintenance safety and emergency protection for equipment and personnel.

Connects EIS system components for fast, real-time data transfer and network communication

Creates frequency-specific signals from 1 mHz to 10 kHz to analyze the impedance characteristics.

Best-in-class precision and stability in signal measurement even at high voltages, coupled with high data integrity and robust noise immunity.

Manages control of raw data acquisition and processes EIS data, operates the system and measurement sequences.

Facilitate direct plug-and-play connectivity for your current transducers (CT) to enhance system integration and ease of use.

Measure and monitor key parameters such as current, voltage, and temperature for comprehensive system diagnostics.

Allows multi-channel temperature measurement at any location for monitoring system integrity under various operational conditions.

Optimizes heat management within the system to maintain stable thermal conditions for accurate measurement conditions.

Offers scalable power solutions from kilowatts to megawatts, catering to a wide range of power requirements.

Technical Features

Data Acquisition Capabilities Q.series X A193 Module

- High-Performance Module: The Q.series X A193 is designed for high-power and industrial applications.

- Signal Amplification and Offset Measurement: This feature amplifies the AC signal and measures in-line DC offset up to 100 kHz per channel. It is crucial for the Lock-In technique and enhances the sensitivity and selectivity of impedance measurements.

- Voltage Measurement Range: Features a 5 V range for DC cell/stack voltage and a 150 mV range for AC signals.

- Current Measurement Flexibility: Current measurement via shunt or current transducer.

- Robust Galvanic Isolation: Offers up to 800 VDC isolation between channels, from channels to the power supply and the bus system.

- Supports EIS on Entire Battery Packs: Specifically designed to handle electrochemical impedance spectroscopy across full battery pack configurations, extending its utility in large-scale applications.

Data Processing and Analysis

- Synchronous Signal Collection: Ensures that all voltage and current signals are collected simultaneously to maintain data coherence and accuracy. Utilizes the Lock-In technique to isolate specific signal frequencies and phases, significantly enhancing the measurement of weak signals in noisy environments.

- Adjustable Reference Frequency: Accepts analog and digital reference signals for power supplies and electronic loads.

- Comprehensive Data Accessibility: Provides raw data access for in-depth time-domain analysis.

Impedance and Voltage Analysis: Automatically calculates impedance at each frequency and measures cell/stack voltage sequentially, providing live dynamic updates throughout the testing process.

System Design and Scalability

- System Frequency Range: Capable of operating across a wide frequency range from 1 mHz to 10 kHz, accommodating a broad spectrum of electrochemical testing requirements. The wide range enhances the Lock-In detection capabilities, making it suitable for various industrial and research applications.

- Modular System Configuration: Easily scalable from a basic setup with 4 channels to complex configurations up to 128 EIS channels, adaptable to project needs from R&D to production scale.

- Temperature Measurement Channels: Includes additional channels specifically for temperature monitoring, integrating thermal analysis with electrochemical impedance measurements.

- Intuitive User Interface: GI.bench software facilitates configuration and visualization, providing a user-friendly interface for managing and observing test progress.

- Real-Time Visualization Tools: Features advanced online process control and visualization tools, including Nyquist and Bode plots.

Integration and Connectivity

- Compatibility with Power Systems: Integrates directly with major power sources and electronic load vendors, ensuring seamless operation within existing setups and reaching 10 kHz with preferred partners.

- Advanced Connectivity Options: Equipped with an open API and EtherCAT interface, the module supports straightforward integration into various automation systems.

Special Feature: Lock-in Amplifier

The Lock-in amplifier technique used in Electrochemical Impedance Spectroscopy (EIS) is a powerful method for detecting and measuring very small AC signals often obscured by noise. This technique involves the input of a reference signal at a specific frequency to the test subject—such as a battery or fuel cell—and the synchronous detection of an output signal at the same frequency. The process effectively isolates and amplifies the signal of interest from the noise using phase-sensitive detection. It enhances the signal-to-noise ratio significantly, making it possible to accurately measure impedance changes over a wide dynamic range and under various conditions.

Here's how the Lock-in concept applies to EIS:

1. Signal Application: A known, small-amplitude AC voltage or current is applied to the electrochemical system.

2. Synchronous Detection: The system’s response is measured synchronously with the applied signal. Only signals at the same frequency and phase as the reference signal are detected and measured, effectively filtering out noise.

3. Phase-Sensitive Output: The Lock-in amplifier produces an output proportional to the cosine of the phase difference between the reference signal and the measured response, enabling precise calculation of both the magnitude and the impedance phase.

Data processing

EIS Engine Plotting Results

Gantner Instruments excels in simplifying the complex data processing involved in Electrochemical Impedance Spectroscopy (EIS) through its sophisticated EIS Engine. Our software and hardware work in tandem to seamlessly transition from raw data collection to detailed impedance analysis, providing critical insights with minimal user intervention.

EIS Plug-in Benefits

- Automated Configuration: The system automatically configures settings for each test, ensuring optimal data accuracy and relevance parameters; this includes setting up the frequency range, signal amplitude, and other critical factors based on the specific requirements of the tested electrochemical system.

- Automated Process Control: The system manages the entire testing process from start to finish, adjusting parameters based on live data as needed. This level of automation ensures consistent testing conditions and reduces the potential for human error, which is critical in maintaining the reliability of high-stakes testing environments.

- Automated Dashboard Creation: With automated dashboard tools, users can quickly create comprehensive visual representations of their data. These dashboards integrate various data points into an easily interpretable format, helping to visualize trends and patterns that may not be apparent from raw data alone.

- Real-Time Data Plotting: As data is collected, the EIS Engine instantly processes and plots impedance spectra. This real-time plotting capability is crucial for immediate feedback during testing, enabling quick adjustments and decisions. The provided graph, showing a typical impedance trace of a lithium-ion cell, illustrates how impedance varies with frequency, offering insights into cell health and functionality.

- Enhanced Data Analysis: The EIS Engine facilitates advanced data analysis techniques, such as model fitting and parameter extraction, directly within the dashboard environment. This integration allows for deeper analysis without needing external software, streamlining the workflow and enhancing productivity.

Deepen Your Understanding

Explore how Gantner EIS has revolutionized operational efficiencies for our clients worldwide. These resources are designed to inform, inspire innovation, and provide practical insights into integrating EIS solutions effectively into your systems.

Explore Real-World Applications with Our Case Study

Uncover the powerful impact of Gantner E.I.S. through our detailed case study. This document showcases specific examples where our EIS technology has been instrumental in enhancing system efficiency and reliability. See firsthand how our solutions are applied in real-world scenarios, driving innovation and operational excellence in energy technologies.

Why do you need Gantner EIS?

Gantner Instruments’ advanced EIS solutions place you at the forefront of electrochemical system optimization – from batteries to fuel cells and electrolyzers.

Our technology delivers precise impedance measurements that reveal critical insights into cell behavior, degradation mechanisms, and dynamic performance – essential for improving stability, durability, and control. Seamless integration with your test infrastructure is ensured via standard interfaces such as Ethernet or EtherCAT.

By enabling accurate characterization across a wide frequency range, our EIS solutions support the development and validation of robust, high-performance electrochemical technologies.

Easy integration into the Q.series X platform

This streamlines the setup process, allowing seamless integration with existing systems, ensuring minimal disruption and maximum efficiency.

Extending your current, voltage, strain, and vibration signals with EIS information

Our systems provide comprehensive data capture, merging traditional measurement types with advanced EIS data, offering a holistic view of system health and performance.

One-Stop-Shop Multi-channel High-Power Solution

Our systems provide a complete suite for EIS testing and can easily handle high-power applications. These features are essential for industries where the scale of operations demands robust, reliable testing capabilities.

Real-time synchronized Data Acquisition of all Parameters

All parameters, including voltage, current, temperature, and strain, are acquired in real-time and synchronized. This synchronization is critical for accurate characterization and ensures that all data reflects the true state of the test subject.

True Multi-channel, No Multiplexing & Shortest possible Analysis time

With support for up to 128 channels, our EIS systems can perform complex multi-channel analysis without needing multiplexing, saving time and increasing the data’s reliability by capturing simultaneous measurements across multiple test points.

Perfect Synchronization with Signals

Our systems are designed to integrate seamlessly with existing setups, supporting signals like temperature, strain, and even video. This integration is crucial for comprehensive diagnostics and analysis.

Rapid Deployment and Easy Integration into Existing Systems

Our EIS solutions’ modular design ensures they can be quickly integrated into existing systems, reducing setup times and enabling a faster transition from setup to full operation.

Expert Knowledge of Integration and Data Analytics

Gantner Instruments is not just a supplier but a full-solution partner in system integration, offering expert knowledge in data analytics and system design. Our open API enhances this capability, allowing custom solution tailoring and integration with third-party systems.

Trusted by Industry Leaders

Our commitment to innovation and precision has earned the trust of industry leaders worldwide.

Discover our EIS Solution

For an in-depth view of how the EIS Measurement System can be implemented in your projects, please download our technical solution flyer here.

Applications

The versatility of Gantner DAQ products makes them ideal for:

GI Productfinder

Find the right products for your application in a matter of seconds.

Questions about EIS?

Talk to our Experts.

Talk to our Experts

Meet now for a hands-on discussion with our EIS experts to understand how EIS can enhance your testing and product development.

FAQ

Up to 100 kHz.

From 1 mHz to 10 kHz.

Technically this is not helpful because you are in the linear range, and measurements at these frequencies are not recommended because it does not cover the behavior of the physical device.

Yes, full integration is supported.

Yes, our platform facilitates this combined measurement.

We offer Q.raxx 3U 19’’ rack form factor

± 5 V (cell and stack voltage), +/-150 mV for AC signal

Yes, both are compatible.

EtherCAT for optimal system integration, Modbus TCP, RTU, CAN, API (XML-RPS), … for seamless integration into your system.

The power device must be able to modulate a sine wave with the desired frequency range. If your existing device is able to provide this function, we can check about the communication. If not, we can supply a booster unit to realize this function.