Aerospace

Our products are well-suited for testing in aerospace engineering applications to accurately and efficiently evaluate the performance, reliability, and safety of aerospace structures and components, such as aircraft engines and structures and space engines and structures. This would include the ability to measure and collect data, analyze the results, and provide them in a useful format for decision making.

Our products meet the rigorous standards and requirements set by regulatory bodies such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA) for aerospace and space testing, and our products are able to withstand harsh environmental conditions and provide accurate and reliable results, in order to ensure the safety and reliability of aerospace and space systems.

Gantner provides reliable and accurate data that can be used to improve engine performance and increase efficiency. A DAQ system can measure a wide range of signals, including temperature, pressure, flow, vibration, and acceleration, and can be used to track engine performance and diagnose problems. Additionally, a DAQ system can be used to create an accurate record of engine performance and help identify any potential issues or maintenance needs.

Gantner’s DAQ system collects data from strain gages, accelerometers, and pressure sensors to measure the response of a structure to various loads and conditions. It can also provide real-time feedback for quick and accurate analysis of test results.

Gantner’s DAQ system integrates a range of sensors, such as pressure sensors, accelerometers, and thermometers, to measure various parameters. It can also provide data logging and analysis capabilities, and is designed to be rugged and reliable for Aerospace testing.

Gantner’s DAQ system accurately measures and records temperature, pressure, humidity, vibration, and other environmental metrics. It can also provide real-time alerts and alarms, allowing for quick and accurate responses to environmental changes.

Gantner’s DAQ system provides accurate and reliable data acquisition, measuring temperature, pressure, acceleration, and more. It can also be used to monitor and control the aircraft’s systems for testing with greater safety and precision, and can be programmed to log data over long periods of time for detailed analysis.

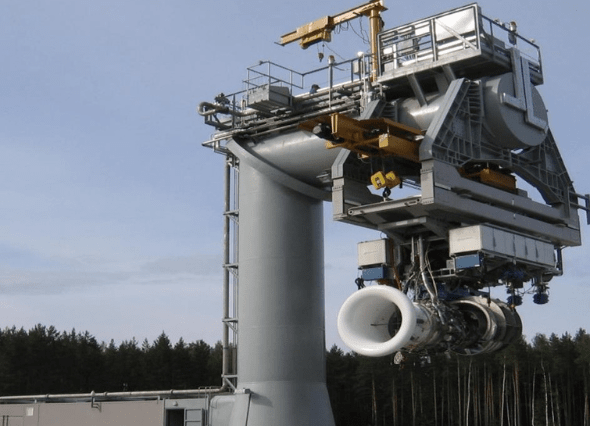

Aerospace Engine Testing

Perform ground testing on engines not yet installed on aircraft (including component testing, bench testing, and altitude testing) and flight testing of aerospace engines to evaluate their performance, reliability, and safety.

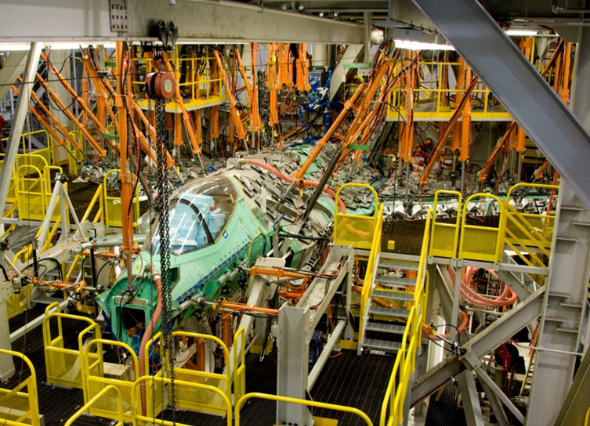

Aerospace Structural Testing

Evaluates the strength, stiffness, and durability of the structures that make up an aircraft, such as the fuselage, wings, and tail. Aerospace structural testing can include static testing, fatigue testing, environmental testing, damage tolerance testing, and flutter testing.

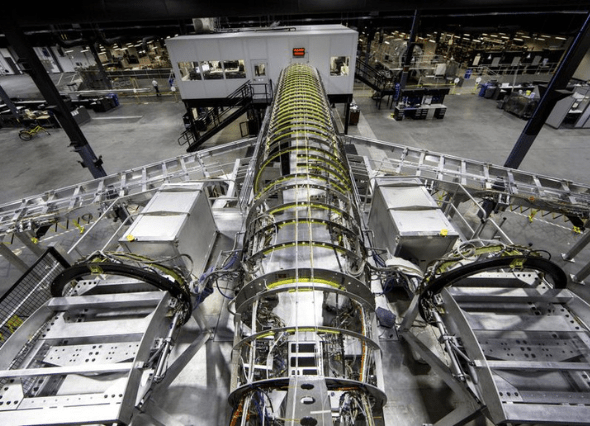

System Integration Testing

Verifies that all the subsystems of an aircraft or spacecraft work together as intended, including testing the integration of avionics systems, propulsion systems, navigation systems, and other subsystems. The testing can be done through physical testing on a prototype or simulated environments, or it can include testing of the software and hardware of the aircraft/spacecraft.

Environmental Testing

Testing aircraft components, systems, and materials in order to ensure they can withstand the environmental conditions they will experience during flight. This includes evaluating their tolerance to extreme temperatures, pressure, humidity, radiation, and other environmental conditions. Testing aircraft components and systems in ensures reliablity and safe operation.

Why Gantner Instruments

Modular Systems Design

I/O modules are available in various packaging styles and designed for multiple tasks. One common hardware platform with multiple housing options allows for using a common measurement platform for development, production, and overhaul testing.

High-Accuracy Thermocouple Measurement

Temperature is the single most important measurement to determine aero-engine performance. Clever input circuits, galvanic isolation, and air-tight casing ensure the highest accuracy in any test environment.

Fully Configurable Data Loggers

Engine testing generates a lot of data with varying sample rates. Mixed-signal, multi-frequency data logging ensures only the data you need is saved, avoiding unnecessary data storage overhead.

Assured Data Availability

Engine testing is expensive a reliable data acquisition system is of utmost importance. Q.series X has multi-level data redundancy to ensure you do not miss a sample.

Direct Data Distribution Service (DDS) integration

Easy-to-use APIs and Apps make it simple to integrate Q.series X into your DDS system for efficient and reliable data distribution in real-time aerospace systems, ensuring safety and security through built-in mechanisms.

What our clients say

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.