Real time data

processing and control

Due to the conflicting trends where structures and systems increase in complexity while development times drastically reduce, test labs are under immense pressure to produce results quickly to save costs despite needing more data from more sensors. Test engineers continuously look for ways to reduce test time and risk while working faster and more efficiently. These engineers must be able to monitor and respond to test data in real time regardless of the data volume.

Real-time data is data that is available as soon as it is collected and can be used to make decisions in the moment. It is often used in situations where it is important to respond to events or changes as they occur, rather than after a delay.

The Challenge of Real-Time Data Processing

The faster you measure, the larger the volume of data you need to analyze and interpret, which can be challenging. To turn this data into actionable insights, regardless of the data volume involved, you need to be able to process and analyze it effectively as close as possible where the data occurs to reduce time-to-insight and network traffic. It’s important to strike a balance between the speed of measurement and the ability to effectively handle and analyze the resulting data. Open platforms providing programmable features, e.g., intelligent logging and sophisticated algorithms, are essential. These features can be performed with our edge computing controllers.

For best results consider the following:

- Perform computation and data storage closer to the point of measurement to improve response times and reduce data transfer bandwidth

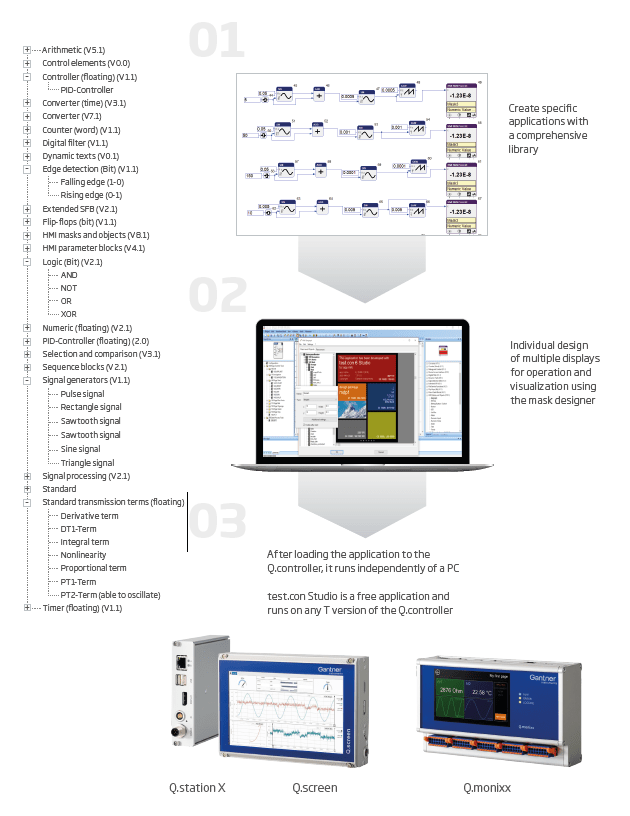

- Run your own Apps on the Edge Device or program with our graphical programming language test.com

- Monitor and respond to test data in real-time regardless of data volume; capture insights from the data you collect, when it happens thanks to open data stream and configuration interfaces

- Post-process with machine learning approach or use established standard analytics, e.g., FFT, Rainflow model, RMS, etc., on our controllers; no PC necessary!

- Reduce data transfer bandwidth to the MAX with the smallest data packages that can be transmitted over, e.g., modems

What is Edge Computing?

Edge computing is a distributed information technology (IT) architecture in which measurement data is processed and analyzed as close to the originating data source as possible, reducing overall data transfer and storage requirements, especially in big data applications. This ideally is performed by edge devices that compute and store at the same location as the data source on the network edge.

What are Edge Devices?

An edge device is any hardware that controls data flow and processing at the boundary between two networks, like a local network and the cloud. Edge devices play a key role in bringing computation and data storage closer to the devices that generate and consume the data. This allows data to be processed and analyzed in real time, improving the efficiency and speed of the system.

Where are Edge Devices for Real-Time Data Processing and Control used?

Edge devices for real-time data processing and control are used in a variety of applications, such as industrial automation, robotics, smart homes, and IoT (Internet of Things). In industrial automation, edge devices are used to process real-time data from sensors and other devices to control processes, machines, and other systems in a factory or production environment. In robotics, edge devices are used to process real-time data from sensors to control the movement and actions of robots. In smart homes, edge devices are used to process real-time data from sensors and other devices to control lighting, temperature, and other functions. In IoT, edge devices are used to process real-time data from sensors and other devices to monitor and control a wide range of connected devices.

Edge Devices for High-Performance Monitoring and Control, Remote Configuration and Universal Connectivity

Gantner Instruments controllers are edge computing devices that transform raw data into preprocessed information for efficient storage, enrichment, and analytics.

High-performance Controller

Q.station X is a high-performance data acquisition controller and edge computing device that provides accurate and reliable synchronization of highspeed measurement data and redundant data logging. It offers an optional full-featured programmable environment, designed for sophisticated automation, control and parallel communication over TCP/IP, CAN, ProfiNet, Modbus, and EtherCAT.

Find out more about how Q.station X can benefit you:

Smart Edge Device for Monitoring Applications

Q.monixx is a new addition to the Q.series product family – the ideal edge computing and data logging solution for reliable process control and asset monitoring. The standard I/O configuration for the Q.monixx includes up to 8 universal analog inputs, 8 digital inputs, 4 digital outputs, 2 relay outputs, and 8 serial channels for communication. Also included are 4 data loggers for parallel data acquisition to either local storage or to a GI.cloud storage solution for easy accessibility, additional analytics, and detailed diagnostics. Third-party apps can also be hosted on the device.

Find out more about how Q.monixx can benefit you:

Scale your DAQ Network with Q.core

The Q.core is a high-performance data acquisition controller with six Ethernet ports for connecting decentralized Q.station X controllers (publishers), one uplink port for data clients (subscribers), two USB ports, an HDMI (optional), and includes a 1TB internal SDD – all in 1U (1.75”) of 19-inch rack-mount space. Stream processing with Q.core provides several benefits like easy data scalability, multi-source data analysis, remote data monitoring, flexibility and support for multiple use cases, standalone data acquisition, and easy integration with GI.cloud.

Find out more about how Q.core can benefit you:

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.

AE

Measuring temperature in components of Hybrid Electric Drives

Click here to request

access to every

GI Application Example

What about data storage?

Depending on the type of test, the duration, and the measurement frequency, an overwhelming avalanche of data is generated. The challenge ahead includes storing and preserving large volumes of data and having the ability to access this data for fast continuous online analysis. Large volumes of structured and unstructured data require increased processing power, storage, and reliable data infrastructure. Combining elements into a scalable data backend can greatly improve time to market, reduce costs, and build better products.

An adaptive and scalable data backend provides a scalable storage and computing platform for acquiring data streams from instruments, storing configurations, and performing analyses.

A separation between hot and cold data is the best choice to cope with constantly changing requirements, setup configuration, parameter extensions, and varying sample rates. Raw data, which is less frequently accessed and only needed for auditing or test post-processing (‘cold data’), is stored in a distributed streaming platform that scales extremely efficiently. If one has to store, process, and calculate new variables from hundreds of thousands of samples per second and hundreds of channels simultaneously, this distributed streaming architecture will show its strength and power.

Connectivity

Access, store and handle your edge device data with high-performance interfaces on GI proprietary platforms or any industrial third-party system using GI.bench’s connectivity.

GI.connectivity fully integrates data storage, security, configuration, authentication and update management from the sensor interface to the data lake. Customers can perform data acquisition on their devices, desktops, or cloud. APIs and microservices permit full scalability and flexibility for third-party data processing or via GI.bench and GI.cloud solutions. Multiple combinations are possible if data or control flows need to be aggregated from numerous edge devices.

Find out more about how GI.bench can benefit you:

Simple Graphical Programming for Edge Computing Devices

Edge devices for real-time data processing and control are used in a variety of applications, such as industrial automation, robotics, smart homes, and IoT (Internet of Things). In industrial automation, edge devices are used to process real-time data from sensors and other devices to control processes, machines, and other systems in a factory or production environment. In robotics, edge devices are used to process real-time data from sensors to control the movement and actions of robots. In smart homes, edge devices are used to process real-time data from sensors and other devices to control lighting, temperature, and other functions. In IoT, edge devices are used to process real-time data from sensors and other devices to monitor and control a wide range of connected devices.

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.

AE

Measuring temperature in components of Hybrid Electric Drives

Click here to request

access to every

GI Application Example

Want to explore Q.series X products?

Search for exactly what you need using our simple-to-use product finder.