Q.boost Power Analyzer

GPA Series

Three-Phase Electric Drive Power Analyzer for Power Quality and Powertrain Efficiency

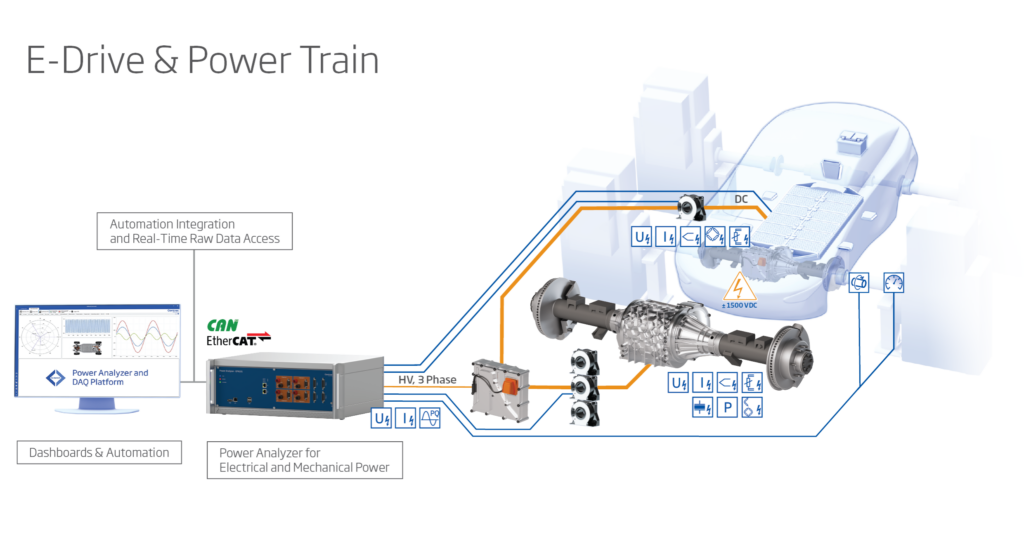

Power analysis in electric vehicle (EV) testing is essential for evaluating the performance, efficiency, and reliability of critical EV components such as batteries, inverters, and electric motors. This testing involves an examination of power quality parameters like harmonics, voltage fluctuations, and power and power factor, which are crucial in optimizing the powertrain’s performance and ensuring its reliability under varying operational conditions. Accurate DC power and mechanical power analysis helps identify the drivetrain efficiency, supporting the development of robust and energy-saving EV systems that comply with industry standards and consumer expectations.

GI.bench – for Modern and Robust Measurement Setups

The GI.bench software platform combines faster test setups, project configuration and handling, as well as visualization of data streams in one digital workbench.

It enables you to configure, execute and analyze your measurement and test tasks on the fly. Access live and historical measurements data anywhere.

With GI.bench’s UI design, experience the difference in accessing high-availability measurement data, anywhere. Witness the power of the new features in action with our Microphone demo.

To optimize your testing and monitoring projects, GI.bench now includes an Oscilloscope widget with sin and rectangle wave functions and new FFT Chart. Enhance your data analysis with the Statistics view in the marker window. Access historical sources from a dedicated tree and view live data with a click. These features of GI.bench enable you to configure, execute, and analyze your testing and monitoring projects more efficiently.

Power analysis offers engineers detailed insights that drive efficiency and performance enhancements across various systems. Through precise measurements of electric drivetrains, including motors and inverters, power analysis pinpoints areas for improvement, directly contributing to better energy management and overall vehicle performance.

- Drivetrain Optimization: Detailed power quality assessments help identify inefficiencies in motor and inverter operations, allowing for adjustments that enhance output and reduce energy waste.

- Enhanced Component Reliability: By evaluating electrical and thermal stress on components, power analysis aids in designing durable EV parts that withstand various operating conditions, minimizing the risk of component failure.

- Compliance with Safety Standards: Conducting power analysis ensures that EVs adhere to international safety and electromagnetic compatibility standards.

- Integrated System Performance: It supports the seamless integration of electrical systems within the vehicle, enhancing the functionality of control units and other critical systems that contribute to vehicle safety and driver experience.

How Power Analysis Works: Measurement and Data Processing Steps

Power analysis not only verifies compliance with stringent industry standards but also uncovers potential improvements. Through rigorous evaluation, power analysis bridges the gap between theoretical design and practical functionality, ensuring that every component operates at peak efficiency. This process involves several key steps:

System Setup

Prior to initiating power analysis, the electric vehicle’s powertrain, including the motor and battery system, is carefully prepared. This involves ensuring all connections are secure and the system is calibrated to accurately measure electrical outputs.

Signal Capture and Conditioning

Measurement devices with high galvanic isolation are used to capture electrical signals from the vehicle’s powertrain. These devices must accurately record the amplitude and phase of both voltage and current across various components, requiring high precision to detect anomalies that could affect performance.

Parameter Selection

Engineers select relevant parameters for measurement, such as speed and torque for mechanical power and DC voltage and current for electrical power to assess the efficiency of power conversion processes and identifying potential areas for energy savings.

Dynamic Analysis

The captured signals are analyzed dynamically, allowing engineers to observe how the vehicle’s powertrain responds under different operating conditions. This includes testing under various load scenarios to simulate real-world driving conditions.

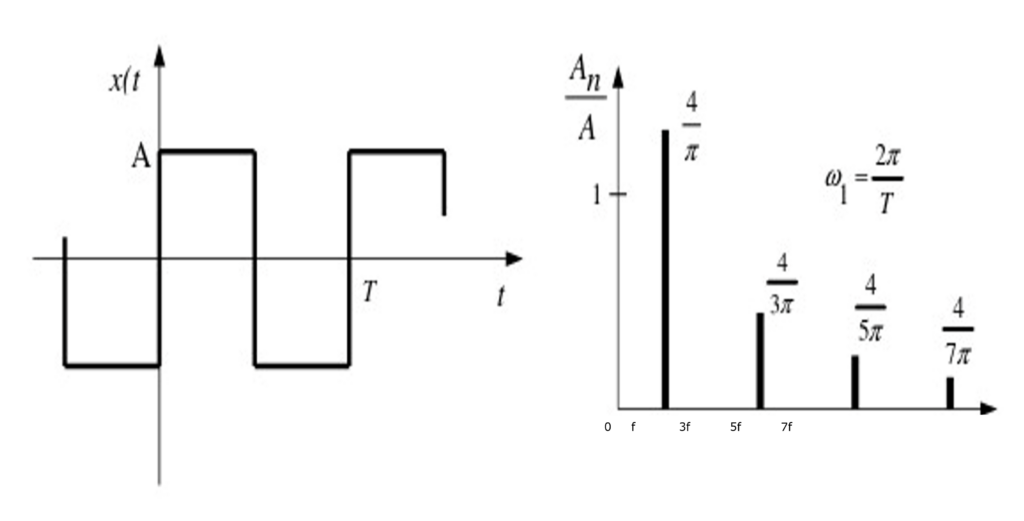

Quality Metrics Assessment

Key power quality metrics such as harmonics, voltage fluctuations, and transient disturbances are evaluated. This step is essential for ensuring that the vehicle will operate reliably and efficiently in a variety of environmental and operational conditions.

Data Integration and Visualization

The data collected from power analysis. These tools help engineers to quickly identify patterns and anomalies in the data, facilitating a deeper understanding of the system’s performance.

Optimization and Troubleshooting

Based on the insights gained from the power analysis, engineers can make informed decisions to optimize the design and operation of the electric vehicle’s powertrain. This might include adjustments to the motor control algorithms or enhancements to the battery management system to improve overall efficiency and performance.

Continual Monitoring and Feedback

Power analysis is not just a one-time procedure but a continuous part of the EV development cycle. Ongoing monitoring ensures that the vehicle maintains high performance and reliability standards throughout its lifespan, incorporating feedback into future design iterations.

This comprehensive approach not only enhances the specific functionalities of each component but also ensures the integrated system performs optimally, reflecting the sophisticated interplay between various subsystems within an electric vehicle.

Our Power Analysis Solution

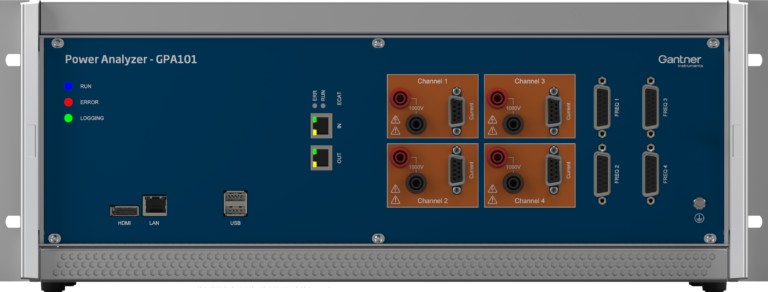

Gantner Instruments’ Power Analyzer GPA Series integrates seamlessly into e-drive test beds for extensive testing of inverters and entire powertrains, facilitated by its EtherCAT interface, which enhances compatibility with modern testing frameworks. The GPA100 measures and analyzes voltage and current signals in three-phase systems, such as electric drives, and evaluates critical power quality parameters including harmonics, interharmonics, voltage fluctuations, transient disturbances, unbalance, and power factor. Additional functionalities include inputs for DC voltage, DC current, torque, and speed meters, extending its utility to the testing of highly integrated e-axles, with options for quality checks and end-of-line analyses. These capabilities ensure that every component of the powertrain is optimized for performance and reliability, reflecting Gantner Instruments’ commitment to advancing EV technology.

Key Components of the Power Analyzer GPA100

- High Voltage and Current Measurement: With up to four high-voltage input channels and four inputs for current transducers, our analyzers meet the stringent requirements of modern EV testing, capturing detailed data across various conditions.

- Advanced Signal Processing: A high sampling rate of 4 MHz per channel and a bandwidth up to 1.7 MHz allow for precise capture and analysis of fast-transient signals within the powertrain, crucial for identifying potential issues before they affect efficiency or safety.

- Integrated Data Handling: The GPA100 features include a built-in resolver for analyzing highly integrated e-axles and options for quality and end-of-line checks, enhancing the analyzer’s utility in production settings.

- Flexible Integration and Data Transmission: The EtherCAT interface, coupled with compatibility with CAN Bus systems, ensures the GPA100 integrates smoothly into existing test setups and facilitates efficient data sharing.

- Comprehensive Power Quality Analysis: Capabilities to assess power quality parameters like harmonics, voltage fluctuations, and transient disturbances help in maintaining the integrity and reliability of the EV’s powertrain.

With up to four high-voltage input channels and four inputs for current transducers, our analyzers meet the stringent requirements of modern EV testing, capturing detailed data across various conditions.

A high sampling rate of 4 MHz per channel and a bandwidth up to 1.7 MHz allow for precise capture and analysis of fast-transient signals within the powertrain, crucial for identifying potential issues before they affect efficiency or safety.

The GPA100 features include a built-in resolver for analyzing highly integrated e-axles and options for quality and end-of-line checks, enhancing the analyzer’s utility in production settings.

The EtherCAT interface, coupled with compatibility with CAN Bus systems, ensures the GPA100 integrates smoothly into existing test setups and facilitates efficient data sharing.

Capabilities to assess power quality parameters like harmonics, voltage fluctuations, and transient disturbances help in maintaining the integrity and reliability of the EV’s powertrain.

Unique Features of the Gantner Power Analyzer (GPA) Series

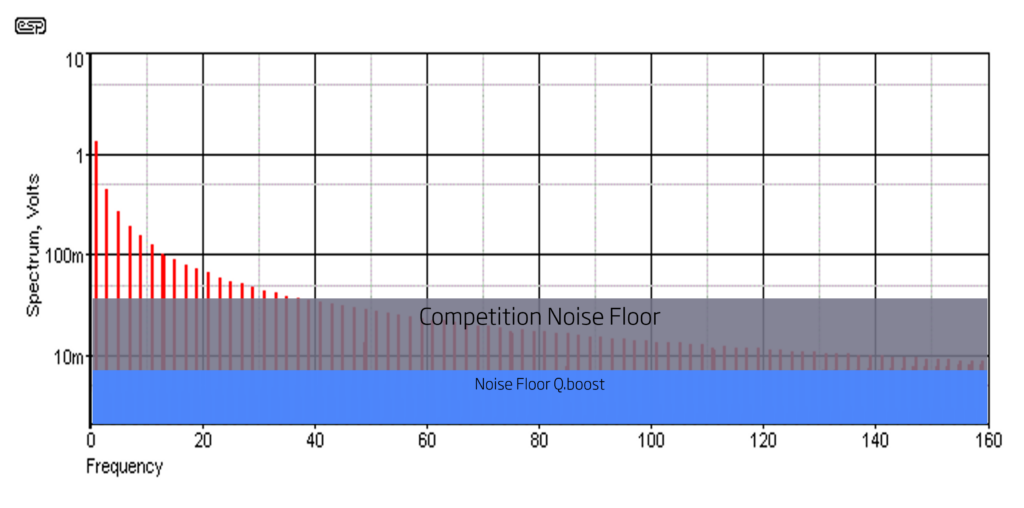

Superior Noise Performance

The GPA100’s advanced design achieves a noise floor significantly below –140dB, allowing for the accurate detection of subtle disturbances and harmonics necessary for determining the efficiency of power systems. This exceptionally low noise floor ensures data integrity, which is critical for applications requiring high-fidelity signal analysis.

Total Harmonic Distortion (THD)

With a THD at less than 3 parts per million (ppm), the GPA100 significantly outperforms other devices in its class. These precise analog inputs are vital for applications where understanding the quality of power and its impact on system performance and durability is crucial.

Comprehensive Power Analysis Capabilities

The GPA100 supports a wide range of measurements including power, power factor, THD, and efficiency, all delivered in real time via EtherCAT. The device is also equipped with a robust data logger and capabilities for high-speed signal capture up to 4 MHz per channel, offering engineers detailed insights into both transient and steady-state conditions.

Form Factor and Integration

The Q.boost Power Analyzer is available in a 19” rack (4U) housing and works seamlessly with the GI.bench software. The system provides two inputs for frequency measurement, making it easy to connect torque sensors with frequency outputs and two counter inputs for speed sensors (tachometers). The raw voltage and current values are always accessible through EtherCAT and our open API.

Your Benefits with Q.boost Power Analyzer

The Gantner Power Analyzer GPA100 is designed for comprehensive power quality analysis in electric vehicle (EV) powertrain testing. This analyzer provides detailed insights into power quality parameters, including harmonics, interharmonics, voltage fluctuations, transient disturbances, unbalance, and power factor.

The Q.boost Power Analyzer by Gantner Instruments is an advanced solution that addresses the challenges in EV powertrain testing and power quality measurement in the automotive industry, providing engineers with accurate and high-resolution data for better analysis, system optimization, and power quality management. With its impressive features and performance, the Q.boost Power Analyzer is an essential tool for engineers working on EV powertrain testing and power quality measurement in the automotive industry.

High-Performance Technical Specifications

- Sampling Rate and Bandwidth: Equipped with a 4 MHz sampling rate per channel and a 1.7 MHz bandwidth, the GPA100 excels in capturing fast-transient signals, essential for accurate powertrain diagnostics.

- Multiple Input Channels: Features four high-voltage input channels and four inputs for current transducers, facilitating detailed measurements across diverse conditions.

Advanced Integration and Connectivity

- Flexible Form Factors: Available in portable (Q.brixx) and 19” rack (4U) variants, compatible with GI.bench software on Windows and Linux-based Q.core controllers.

- Enhanced Data Access: Utilizes an open API and supports EtherCAT and CAN Bus interfaces, allowing seamless integration into automation systems and easy access to raw voltage and current values.

Versatile Inputs and Exceptional Accuracy

- Comprehensive Input Range: Supports input ranges from ±500 mV to ±1500 V with galvanic isolation of all channels, suitable for high-voltage applications.

- Superior Signal Conditioning: Achieves less than 3 ppm distortion and a noise floor below -140dB, ensuring the highest accuracy in power calculations.

Unique Features and User Benefits

- Seamless System Integration: The analyzer can be integrated smoothly into existing setups, enhancing workflow efficiency with its EtherCAT interface for real-time data transfer.

- Practical Testing Applications: Includes built-in features for resolver testing and connections for torque and speed sensors, making it versatile for various testing scenarios.

- Exceptional Power Quality Analysis: The GPA100 not only measures but also provides in-depth analysis of critical power quality parameters, helping engineers to identify potential issues and adjust system configurations to optimize performance.

Discover our Power Analyzer Solution

For an in-dept view on the technical benefits please download our solution flyer here.

Want an easy way to explore Power Analyzer products?

Search for exactly what you need using our simple-to-use product finder.

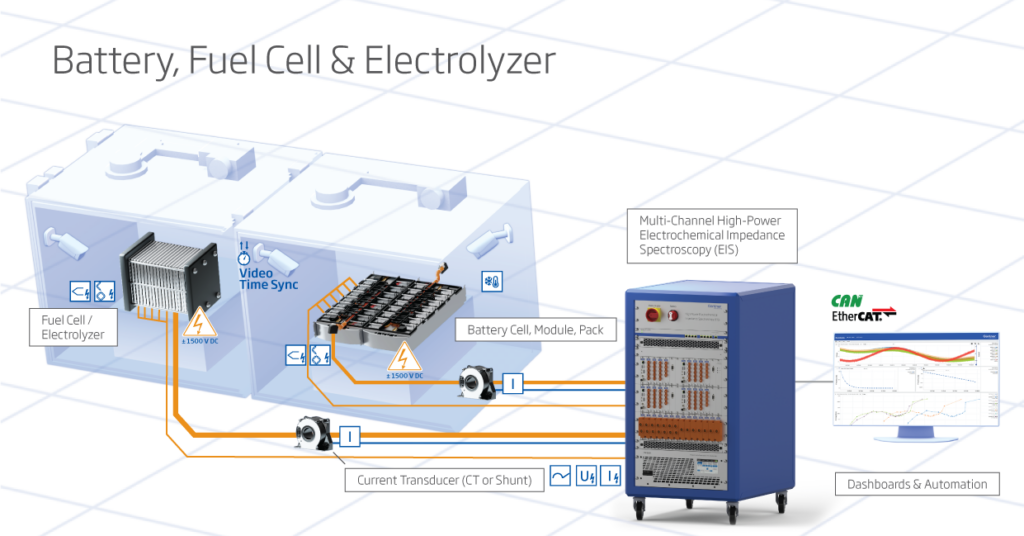

Applications

The versatility of Gantner DAQ products makes them ideal for:

GI Productfinder

Find the right products for your application in a matter of seconds.