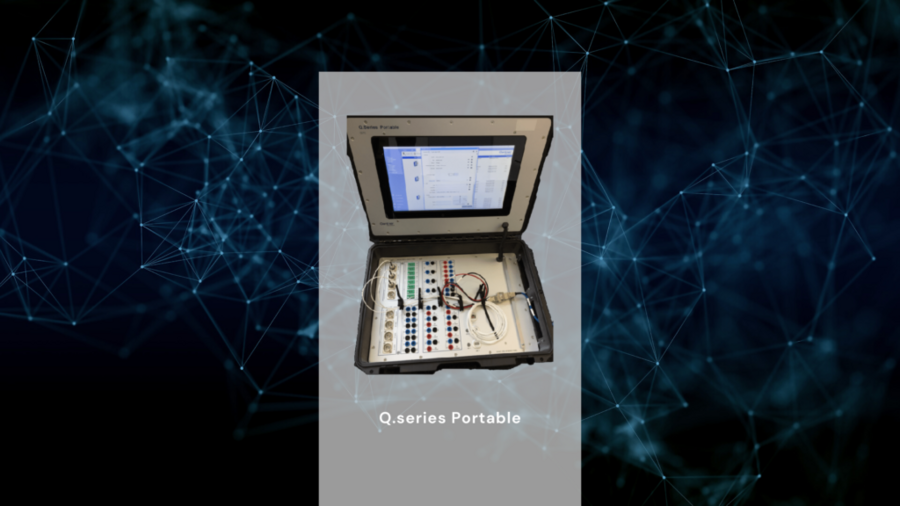

The Q.series Portable is available in two versions:

- Q.series Portable – Standard with up to 32 user defined channels

- Q.series Portable – Extended with up to 64 user defined channels and inbuild touch Display

Both versions have inbuild storage device extendable with USB drives and can be extended by further modules e.g. Q.staxx on two UARTS. With customized plugs and sockets for sensor connection and inbuild sensor excitation for example for MEMS sensors the system is ready to use after very short installation time. With special cable entries sensor cables with installed plugs can be inserted into the transport case while providing an IP protection grade of IP54 / IP63 (depending on type of cable entry).

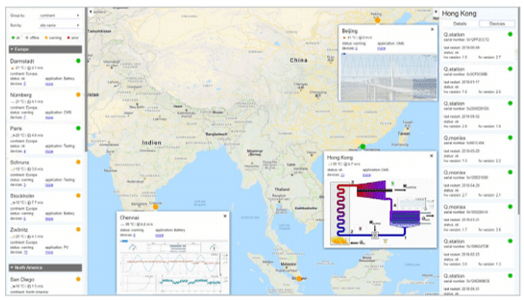

The Q.series Portable can be installed close to a machine, equipment, plant, etc. or extended across a large area with daisy chained additional modules. Connectable and networkable by Ethernet to other Gantner DAQ systems or remote computers for data visualization, data can be internally logged with inbuild storage or accessible USB drive ports. With the OPC UA interface of the Q.station also an online connection to SCADA systems is possible. 4G/LTE Modem for automated data transfer to customer host or GI.cloud can be ordered as an option.

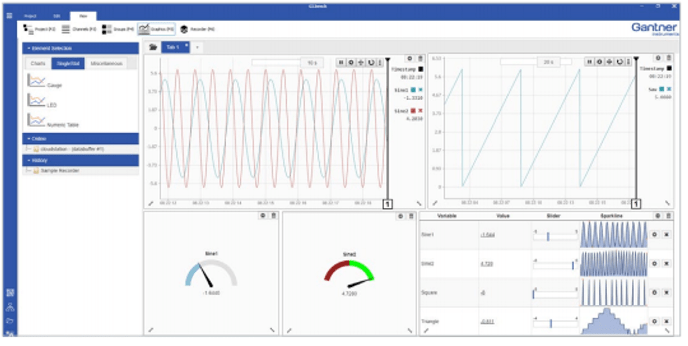

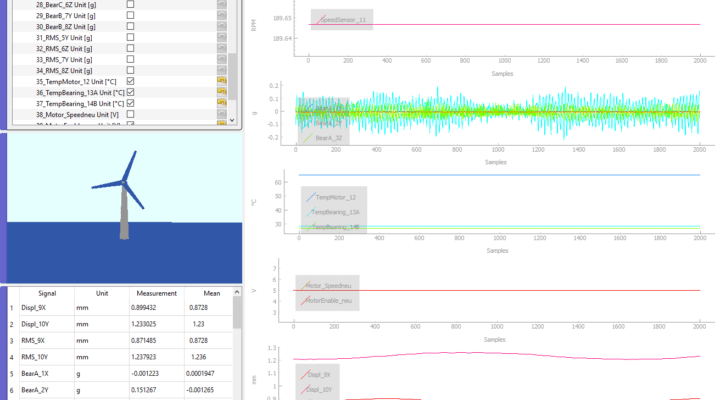

With the different interfaces you have the choice to use it as a stand-alone data logger or visualize the live data on GI.bench, GI.cloud or with a customized user interface made with Python.

For more information about the Q.series Portable you can check out the flyer:

More articles

How to enhance your EtherCAT master with best real-time DAQ

Connectivity and flexible integration of our high-accuracy and high-speed I/O modules into any automation system is in our DNA. Therefore you are now able to integrate our high-performance Q.series X I/O modules into all industry standard EtherCAT masters like TwinCat, Koenig KPA, NI VeriStand, and Acontis.

Read more...New Monitoring Solution – Q.series Portable

For short-term or rout-based condition monitoring of various assets we now provide a portable system solution. Our new Q.series Portable based on Q.station 101 and OEM-boards for analog and digital inputs contained in a robust transport case is fully engineered and ready to use ‘out of the box’. The electronic boards and the power supply system are mounted on shock absorbers to withstand heavy-duty work under harsh environments in the field.

Read more...Test Like You Fly, Fly Like You Test

When building a rocket there is a whole flight certification process, and qualification is an important part of that. It proves the hardware meets the requirements and performs the way it is designed to do. Of all parts of a rocket, the engine section is perhaps the most critical during launch. The weight of the massive rocket is pushing down, while the engines are pushing up with millions of pounds of thrust. Whether it is an engine for experimental rockets or for commercial spaceflight, adequate testing is critical to the success of each launch program.

Read more...Test of Battery and Battery Management Systems

At a very early stage Gantner Instruments was involved with special products for testing of batteries in the E-Drive environment. An already existing and successful product range is now supplemented with a useful novelty.

Read more...