Overview

The new trains in Singapore are part of Land Transport Authorithy`s efforts to enhance existing rail capacity for the coming years. Out of the 42 trains, 18 trains are aimed at the North East Line (NEL) of the network while the Circle Line (CCL) will receive the 24 trains. This will improve fleet capacity by 60-70% on both lines.

The Gantner Solution

Once train cars shipped to Singapore they carrry out testing before they put them in to operation.

Test Measurement and Control system from Gantner Instruments equipped with multi-channel analog input modules and Dynamic High Voltage input modules with high isolations for Train testing for the complete driverless metro system designed and constructed by Alstom which are operating on NEL (North East Line) and CCL (Circle Line) Railway lines. The Alstom Metropolis C830 are the second generation of communication-based train control (CBTC) rolling stock currently using in Mass Rapid Transit (MRT) lines to meet the growing demand of passengers in Singapore.

NEL (North East Line) project

1 x Q.brixx station

1 x Q.brixx A101

2 x Q.brixx A107

2 x Q.brixx A128

CCL (Circle Line) project

1 x Q.brixx station

1 x Q.brixx A107

1 x Q.brixx A128

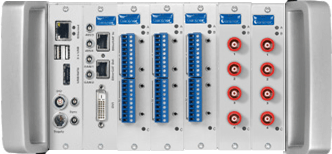

Q.brixx station

The powerful Q.brixx station is a programable test controller with logger functions.

Q.brixx A101

The Q.brixx module A101 with two universal inputs was selected for vibration measurement to provide fast high accuracy digitalization.

Q.brixx A107

The high density Q.brixx module A107 was selected to provide precise, isolated, noise free strain gage measurements.

Q.brixx A128

The Q.brixx module A128 with 4 galvanically isolated input channels was selected for high voltage testing.

More information about our products can be found in the product finder:

More articles

Q.series X A192

The Multifunction Module when Flexibility and the Highest Performance Matters Most

Read more...The 10 most important principles for effective acceleration measurement and vibration monitoring

In vibration monitoring and acceleration measurement, there are many variables to consider, and many opportunities to make mistakes. Sometimes it is nice to have a checklist that keeps you on the right track. Here are the 10 essentials for effective vibration monitoring and acceleration measurement

Read more...Designing SHM as Long-Term Measurement Infrastructure

Across the United States, bridges, tunnels, dams, and large industrial structures are being pushed beyond their original design life and asked to carry higher traffic volumes, heavier freight, and more frequent extreme events. At the same time, the U.S. regulatory and asset-management environment still depends heavily on periodic inspection programs and documented condition data.

Read more...Measurement Explorer – Simplify Your Data Management with GI.bench

Engineers managing complex test setups know the frustration of hunting through countless data files, sensor channels, and historical records. The new Measurement Explorer in GI.bench addresses this challenge head-on, streamlining data management into a unified, intuitive, and fast user interface.

Read more...