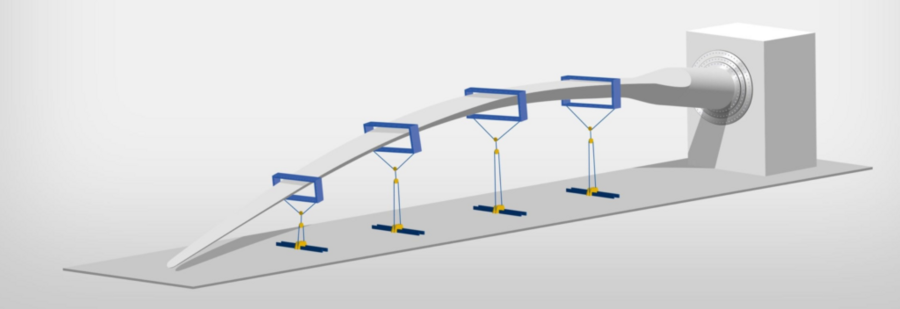

As the size of wind turbines whose blades will soon exceed the 100 m mark and generate power of up to 8 MW, the question of the material (composites) and its strength is an ongoing issue. The Danish Test Center BLAEST in Aalborg has specialized in the testing of components of wind turbines.

The test center BLAEST, owned by the leading wind technology institutes Force Technology, Technical University of Denmark (DTU – Risø) and Det Norske Veritas DNV Germanischer Lloyd – GL operates several test stands for strength and fatigue testing of rotor blades.

The prototype of each rotor blade has to be tested before approval, and series production on its strength. These tests are carried out in accordance with IEC 61400-23. BLAEST is certified for the complete test.

Read on this topic, our cover story in the issue 03/2016 of the journal mpa here!

More articles

Precision Quiescent-Current Measurement with Q.raxx X slimline A108 2SC

Quiescent current measurement is essential across various industries, notably in the development of battery-powered devices, automotive electronics, and energy-efficient technologies. Also known as standby current, this crucial parameter measures the current in electronic systems during idle states, significantly impacting power consumption, battery longevity, and overall efficiency. Minor inaccuracies in its measurement can lead to considerable consequences.

Read more...PV & Grid Integration Symposium

Meet us at the 2019 PV Systems Symposium, the leading industry get together for PV Monitoring and grid integration in Albuquerque (New Mexico), United States.

Read more...Mercedes GLC 350e plug-in hybrid – Photo Session in Schruns

Daimler used our company building in Schruns as the backdrop for the photo shoot for this year’s world premiere of the Mercedes-Benz GLC 350e plug-in hybrid.

Read more...Portable and Mobile Data Acquisition Systems

There are many reasons for a flexible and robust measurement system that must be easy to transport to collect measurement data at different locations. These can be, e.g., short-term measurements on machines or plant components during commissioning after maintenance or recurring measurements on bridges or other engineering structures.

Read more...