For the testing of these e-drives, we implemented the data acquisition solution and evaluation for a large German automotive supplier. Power consumption and speed are relevant to evaluating the efficiency of electromechanical systems. Since the motors are permanently installed into vehicle body parts, often only the electrical current and voltage signals are all that’s available for quality testing.

Using the Current Signal to Determine Motor Speed

In a classic DC motor, the mechanical commutator leads to a brief drop in the current curve when poles are reversed. Depending on the design and number of poles of the motor, the quantity of current dips corresponds to one revolution. This model is also reflected in the current curve of brushless motors with electronic commutation.

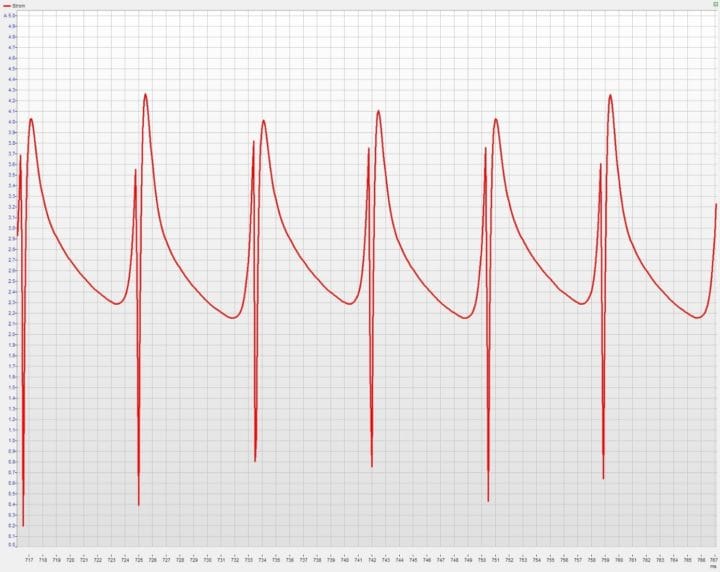

Figure 1 demonstrates the current curve of a motor over time. The current pictured here was measured with a Q.bloxx XL A107 I/O module and a shunt. The current drops visible in this example occur during commutation at intervals of 8.4 ms.

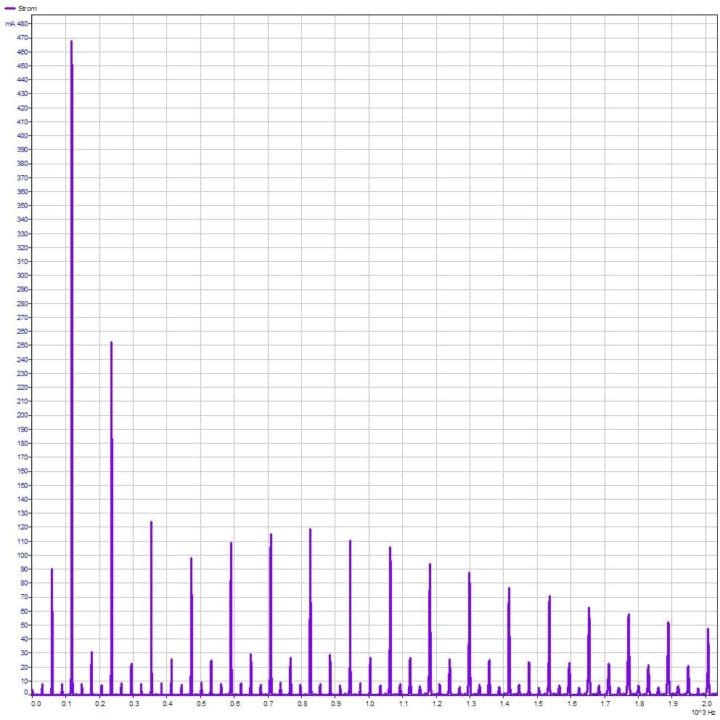

Accordingly, the spectrum of the current curve (Figure 2) shows its maximum occurs at 119 Hz. Assuming 3 commutations per revolution, this corresponds to a speed of 2380 revolutions per minute.

The spectrum can be performed both online and offline by Q.series X controllers. In this way, the engine speed can be determined continuously and live on the test bench using the current signal. The necessary configuration is performed in just a few steps.

Quick-and-Easy Configuration on the Test Bench

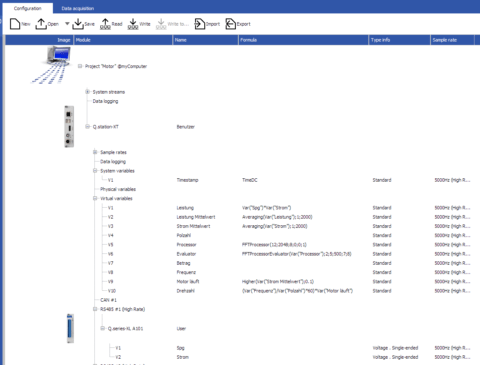

The FFT function of the Q.series X controller offers, among other things, the possibility to evaluate the maximum of a spectrum within a selected frequency band by magnitude and frequency. The frequency of the maximum corresponds to the fundamental wave and is divided by the number of poles and multiplied by 60 to give the speed in revolutions per minute (rpm). Also, the current is used to detect whether the motor is in operation and whether the electrical power can be calculated.

This edge computing allows the motor speed to be determined without a separate computer.

Depending on the test bench configuration, data can now be transferred to the system control, e.g., via EtherCAT or visualized within GI.bench on the test bench PC or over the local network.

Simply Powerful Visualization

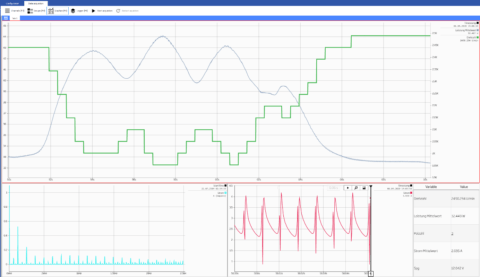

With GI.bench, you can create custom dashboards for visualization. Figure 4 shows the speed and power in the upper chart. When the motor is loaded, the speed decreases (green curve), while the power consumed increases (grey curve). Also, the current spectrum (blue), the current trace (red), and the parameters (table) are displayed numerically in this interface.

For references, demo programs and questions you can always contact us at info@gantner-instruments.com.

More articles

Gantner Instruments TechDay

On April 28, 2026, Gantner Instruments invites you to the GI TechDay DACH 2026 at their headquarters in Schruns, Austria. Join this free event focused on testing and inspecting electric drives, batteries, and fuel cells.

Read more...Putting Intelligent Heat Pump Control to the Test Real World Performance Evaluation

Given the increasing share of renewable energies in the electric energy system, flexibilities are key to match production and demand. Domestic heat pumps are expected and promoted to further increase as a key technology. Research is ongoing to utilize these heat pump systems and their thermal storage as flexibilities within the electrical energy system’s superordinate level.

Read more...Innovation in Alpine Solar: Overcoming Winter Energy Challenges

Switzerland is investing in the untapped potential of Alpine photovoltaic (PV) generation and making strides toward a sustainable future. This blog explores the innovative Sedrun Solar project, a pioneering high-altitude PV initiative to fill the winter energy gap. Uncover how rigorous testing and insightful data collection, facilitated by Gantner Instruments, are paving the way for optimizing this renewable energy source.

Read more...High Performance Measuring Module D107 for Frequencies

The Q.bloxx D107 is a new measurement module for the acquisition of frequencies and incremental signals. Due to its fast signal conditioning capability with a clock speed of 288 MHz, the new module is suitable for extreme measurement of rotational speeds, which were not previously possible in this price range.

Read more...