Gantner Instruments is launching a brand new Optical Gage Amplifier that offers all the benefits of fiber optic measurement, but without the hassle!

What is the F108?

The new F108 Optical Gage Amplifier combines unique fiber optic sensor technology with the modularity and versatility of the Q.series X product line. For quick and easy setup you can use GI.bench and even combine it with GI.cloud for cloud-based storage and monitoring.

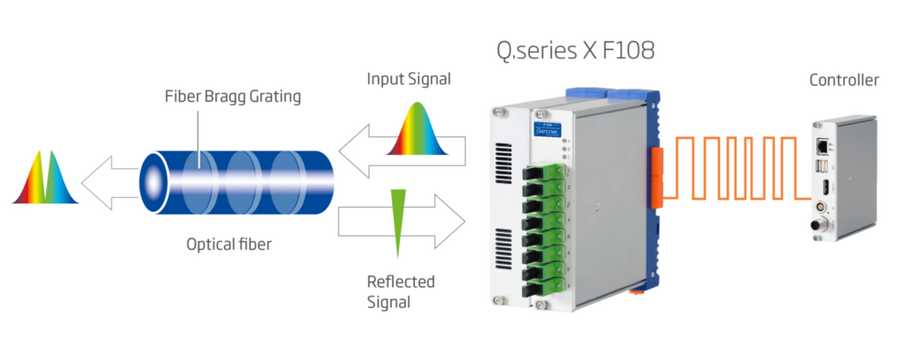

The Q.series X F108 is designed for fiber optic π-phase-shifted Bragg grating (πFBG) for high resolution measurement. A laser with a narrow tuning range (~4 nm, nominally ~1548-1552 nm) is used to lock to the dip seen in a πFBG and to track that point as the sensor is subjected to changes in temperature or strain. Or in other words, smaller signal peaks can be measured and that is what makes the measurement more accurate and precise.

What do you have to do to use the unique optical sensor technology for your tasks in DAQ projects? You simply have to plug in… and you can start to measure!

We at Gantner Instruments optimized the signal’s way from sensing element to transducer to signal conditioner, to address a wide range of precision measurement challenges.

In which environments can you use the F108?

Fiber optic measurement technology comes with the big advantage of not being sensitive to environmental interference. Lightning strikes? No problem at all for the F108! Fiber optic sensors are intrinsically safe and can be put to use whenever the conditions are grim.

Why F108 and not any other fiber optic measurement product?

Unlike other fiber optic interrogators the technique used in Gantner Instruments’ F108 stands out with an unsurpassed measurement uncertainty, e.g. for temperature it is +/‑0.2 °C relative. Yes, you read it right – our fiber optic technology is that good! And what makes it stand out even more is that we took the technology and put it right there where you need it – a seamlessly integrated DAQ system.

- Plug in and measure: Start taking measurements from the moment you plug in.

- Measure faster: Single channel measurement speed of 10 kS/s

- Just another member of the family: Fully compatible with the Q.series X product line and GI.bench for easy set up & data acquisition

- 8 independent measurement channels

Do you want to learn more about Q.series X F108?

For further information visit our F108 website where you can download data sheets or contact your local Gantner Instruments sales representative.

More articles

Gantner Instruments Environment Solutions celebrates its 10th company anniversary and starts with a ground-breaking ceremony for the construction of another company building

Over the past ten years, Gantner Instruments Environment Solutions GmbH has grown into a global market leader of monitoring and control solutions for large-scale solar systems.

Read more...Korea Aerospace Industries selects Gantner Instruments for Structural Testing

Korea Aerospace Industries (KAI) has selected the Q.raxx slimline DAQ system from Gantner Instruments for static strength and fatigue evaluation testing of the LCH/LAH helicopter airframe, main landing gear, and engine mount structure.

Read more...Airbus Helicopters Chooses Gantner to Upgrade their Fatigue Test Cells

Airbus Helicopters (formerly Eurocopter Group) is a global helicopter manufacturing and support company. It is the largest in the industry in terms of revenues and turbine helicopter deliveries. With the growth and advancement of their product offer, Airbus Helicopters identified a need to upgrade their component test benches at their newly enhanced manufacturing location in Donauwörth, Germany.

Read more...Austrian Railways Measurement Vehicle Detects Signal Magnets Using the Q.station Test Controller

The Austrian Federal Railways (ÖBB) continuously checks the quality of its network using special measurement vehicles. Measurement data is required as the basis for maintenance and renovation work; a precise geographic reference data is therefore important.

Read more...