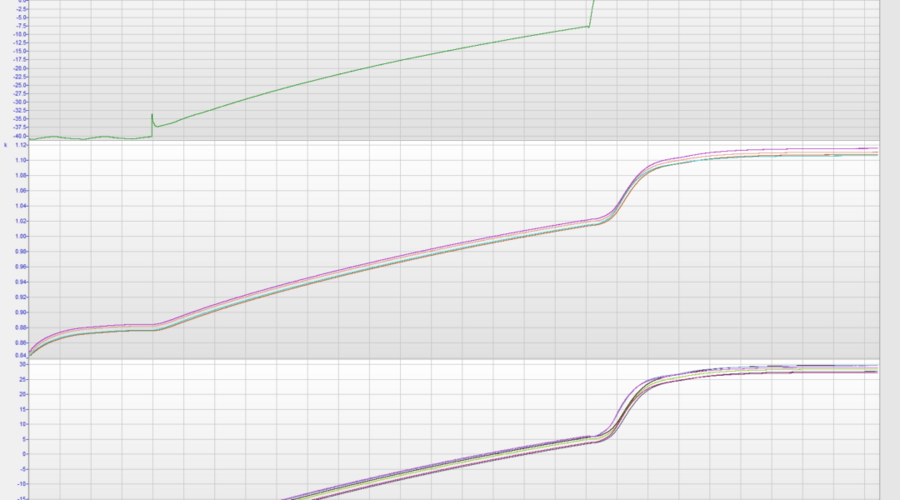

The Q.bloxx XL A104 TCK provides 8 channels for thermocouples (here as Type K, NiCr/Ni) with standard miniature front sockets.

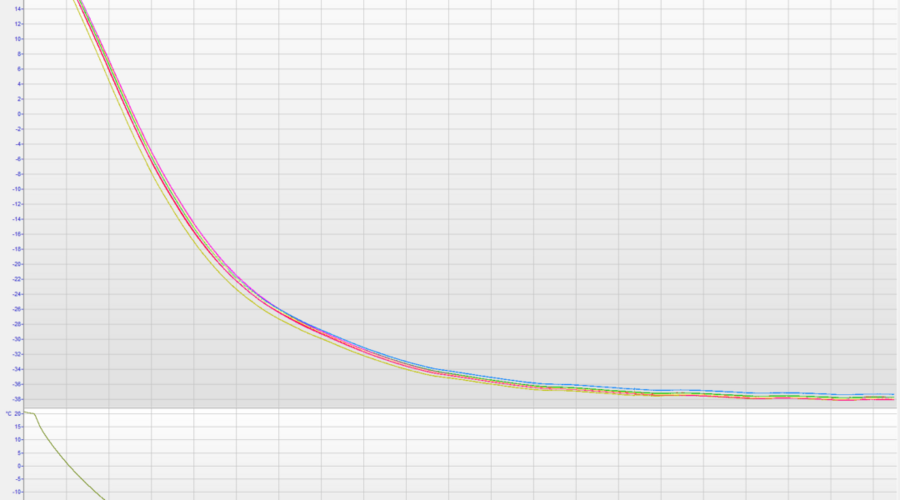

During a day in the climate chamber at -40°C it was completely frozen. After connecting with power supply to the I/O module it was delivering stable and precise measurement values. When temperature was increasing it passed dew point. We observed no impact on the measurement quality or from condensation during this phase. Our I/O module passed this test successfully – even when the datasheet recommends only -20°C operating conditions.

More articles

Project State Overview – Real-time Visibility and Control with GI.bench

Engineers managing complex test setups know the frustration of hunting through countless data files, sensor channels, and historical records. The new Measurement Explorer in GI.bench addresses this challenge head-on, streamlining data management into a unified, intuitive, and fast user interface.

Read more...Turbomeca Chooses the Q.series

Turbomeca is a french manufacturer of compressors and turbines for the aviation industry, among its customers Eurocopter, Augusta und Sikorsky. For the test and measurement design of future test stands were the products from four manufacturers tested, and the companies rated on quality in production, and in all functional processes. Turbomeca selects Gantner Instruments GmbH as manufacturer and accredited according to strict rules. Gantner Instruments is exclusively represented by BGP Electronic in France.

Read more...Three steps to the Internet of Things (IoT) or: Where is analog big data derived from?

The break-up into the new era of Internet of Things (IoT), industry 4.0 or cloud computing takes an impressive pace and is also in several industrial applications irresistible. The industry with its huge amount of machines and components of divers size, value and function is faced by one big challenge: data from all these assets needs to be gathered and analyzed.

Read more...Korea Aerospace Industries selects Gantner Instruments for Structural Testing

Korea Aerospace Industries (KAI) has selected the Q.raxx slimline DAQ system from Gantner Instruments for static strength and fatigue evaluation testing of the LCH/LAH helicopter airframe, main landing gear, and engine mount structure.

Read more...