Controllers for DAQ system

Gantner Instruments understands that validation and certification of aircraft structural components are expensive and time-consuming. The accuracy and moreover the precision of strain gage measurements are of greatest importance to exactly determine the durability and damage tolerance design of a structure. The costs and risks involved are substantial, pressure for quick entry into service is high, whilst sensor density and data produced during a structural test program are increasing progressively. The design of the Q.series X data acquisition system is aimed at maximizing test efficiency, and reducing overall test cost and time.

Q.series X –

Next Generation

in Data Acquisition

The allowable ultimate stresses must not be exceeded at the design ultimate load for at least 3 seconds (static), normally 1.5 times the maximum load in the design case. In addition, it must be shown that no detrimental deformations occur at loads of at least 75% of the design’s ultimate load.

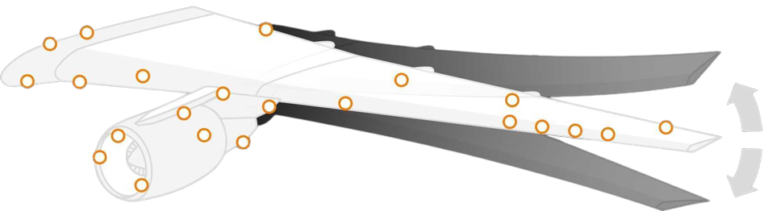

Fatigue testing of the full-scale airframe, wing, or landing gear, must show that catastrophic failure due to fatigue, corrosion, manufacturing defects, or accidental damage, will be avoided throughout the operational life of the airplane.

Low and high cycle fatigue testing to obtain mechanical properties like stiffness and failure strength and validate the safe and economical service life of the component.

Thermal Structural Testing, or Thermal Stress Testing, is a method of testing a structure’s or material’s ability to operate safely at different temperatures to understand its safe operating limits and potential lifespan.

Application Examples

AE

Measuring temperature in components of Hybrid Electric Drives

See all Application

Examples for

Mobility,

Energy,

Aero & Space,

Civil Engineering

and more …

Why Gantner Instruments

01

High Strain Gage Measurement Certainty

More about GI

02

Reliable, Multichannel Data Processing

More about GI

03

Multi-frequency and Redundant Data Logging

More about GI

04

Open Interfaces for Cost-Effective Monitoring of Complex Tests

More about GI

05

Nanosecond Time Synchronization Between All Channels

More about GI

06

Future-proof

More about GI

What our clients say

FPT Fiat Powertrain Technologies – Heavy Duty Engines

Mahle Behr – Automotive Air Conditioning

Max-Planck-Institut for Plasma Physics – Nuclear Fusion Research

Schäffler Group

Safran Turbomeca – Turbo Engines

Bombardier

GradientWind

Chevron

AIRBUS Helicopters

Johannes Eidnes, Product Manager, A&D

DESY cherenkov telescope array (cta) Group

Safran Helicopter Engines

S. J. Choi, DNV, Korea

Dr. Makiola, KSB AG

Mr. Erasto Maleche, ITER Organization, Tokamak Complex Division

Questions about Aerospace Structural Testing? Talk to our Aerospace Experts.

Gantner Instruments assures that your contact data will remain confidential. From time to time, we would like to contact you about our products, as well as other content that may be of interest to you.