NOV (National Oilwell Vacro) is a global company in the fields of drilling and conveying technology. NOV supports the world’s most advanced drilling solutions in the oil and gas industry.

Here almost 150 measuring channels are used in a test system:

- 10 x IEPE with 5 x Q.bloxx A101

- 24 x current with 3 x Q.bloxx A108

- 12 x Pt100 with 3 x Q.bloxx A107

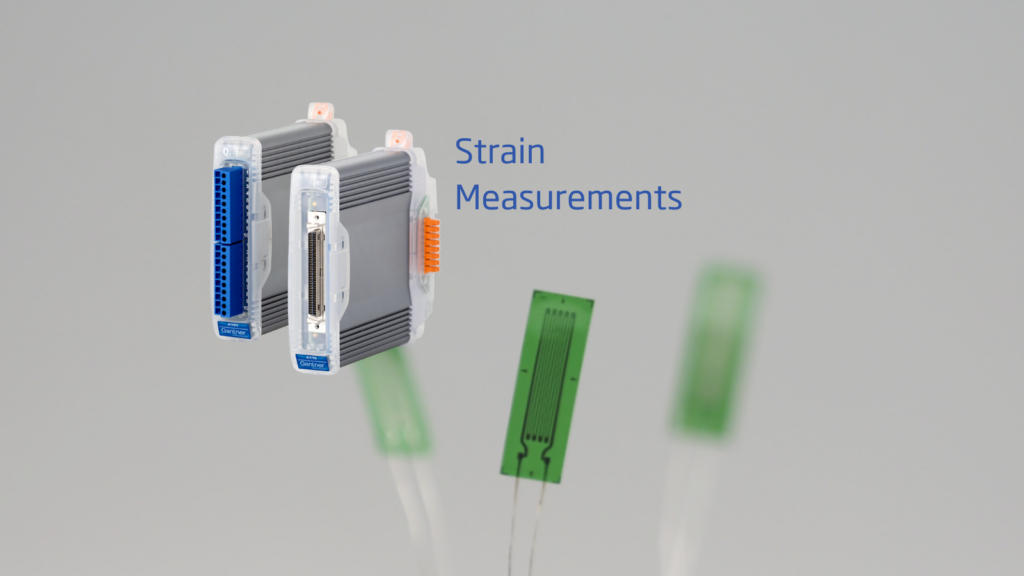

- 96 x SG with 12 x Q.bloxx A116

- Multiple digital I/Os

The measured data is recorded at a sample rate of 10 kHz. A data logger was configured in the Q.station test controller that records the conditioned and raw data. The recorded data is transferred to a SQL database using the test.node server software.

At present, four test systems are being built; with additional systems being planned. Testing is performed in cooperation with our Danish partner IPC Teknik ApS.

More articles

Gantner Instruments and PhotonFirst Sign MoU

Gantner Instruments and PhotonFirst have signed an MoU to advance fiber optic sensing technologies. This partnership focuses on innovative measurement solutions.

Read more...Gantner Instruments Environment Solutions celebrates its 10th company anniversary and starts with a ground-breaking ceremony for the construction of another company building

Over the past ten years, Gantner Instruments Environment Solutions GmbH has grown into a global market leader of monitoring and control solutions for large-scale solar systems.

Read more...Fuel Cells: Advanced Measurement Techniques and Navigating the Hydrogen Market

The energy landscape is in a state of flux, shifting towards sustainable practices, and fuel cells have risen as a promising beacon of renewable energy. The mastery of fuel cells, their inner workings, and the nuances of their measurement, is central to this paradigm shift towards green energy. These devices, which are essentially electrochemical cells that transform chemical energy into electricity, promise a more sustainable, carbon-neutral future, provided we can harness their full potential. This blog post delves into the captivating scientific universe of fuel cell measurement, elaborating on the methodologies, complexities, challenges, and breakthroughs that make fuel cell technology so intriguing.

Read more...Innovation Call Vorarlberg 2023

Digital Innovation: Fueling the Future and Unveiling the Unseen

Read more...