For the testing of these e-drives, we implemented the data acquisition solution and evaluation for a large German automotive supplier. Power consumption and speed are relevant to evaluating the efficiency of electromechanical systems. Since the motors are permanently installed into vehicle body parts, often only the electrical current and voltage signals are all that’s available for quality testing.

Using the Current Signal to Determine Motor Speed

In a classic DC motor, the mechanical commutator leads to a brief drop in the current curve when poles are reversed. Depending on the design and number of poles of the motor, the quantity of current dips corresponds to one revolution. This model is also reflected in the current curve of brushless motors with electronic commutation.

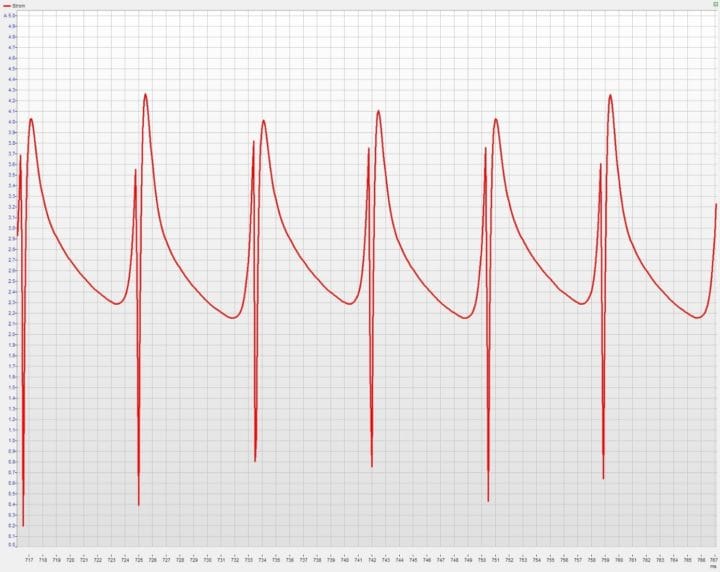

Figure 1 demonstrates the current curve of a motor over time. The current pictured here was measured with a Q.bloxx XL A107 I/O module and a shunt. The current drops visible in this example occur during commutation at intervals of 8.4 ms.

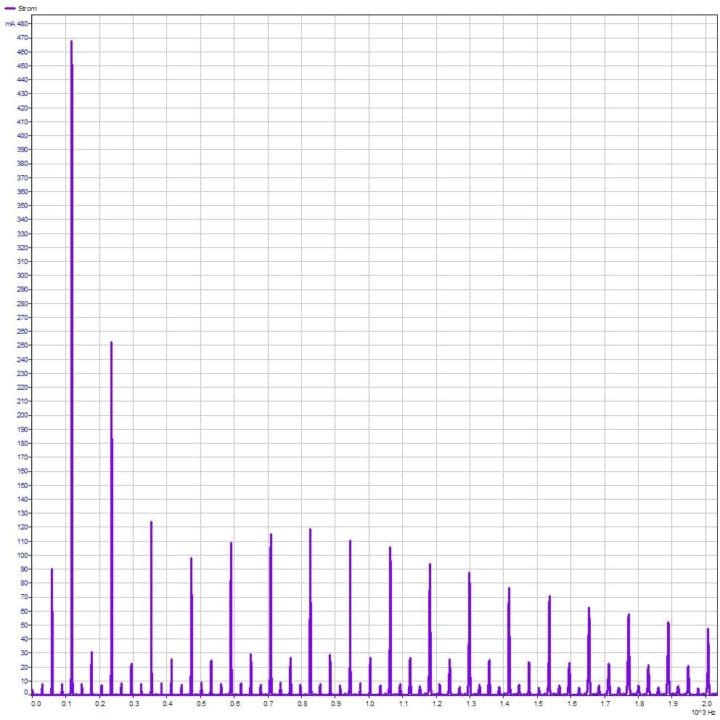

Accordingly, the spectrum of the current curve (Figure 2) shows its maximum occurs at 119 Hz. Assuming 3 commutations per revolution, this corresponds to a speed of 2380 revolutions per minute.

The spectrum can be performed both online and offline by Q.series X controllers. In this way, the engine speed can be determined continuously and live on the test bench using the current signal. The necessary configuration is performed in just a few steps.

Quick-and-Easy Configuration on the Test Bench

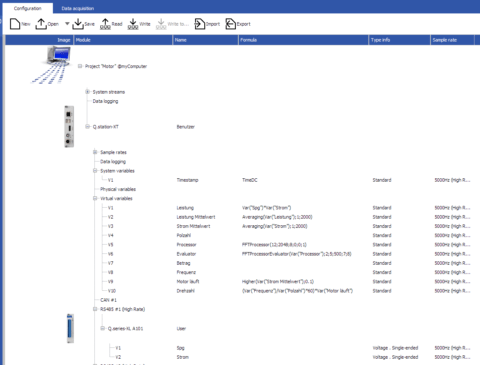

The FFT function of the Q.series X controller offers, among other things, the possibility to evaluate the maximum of a spectrum within a selected frequency band by magnitude and frequency. The frequency of the maximum corresponds to the fundamental wave and is divided by the number of poles and multiplied by 60 to give the speed in revolutions per minute (rpm). Also, the current is used to detect whether the motor is in operation and whether the electrical power can be calculated.

This edge computing allows the motor speed to be determined without a separate computer.

Depending on the test bench configuration, data can now be transferred to the system control, e.g., via EtherCAT or visualized within GI.bench on the test bench PC or over the local network.

Simply Powerful Visualization

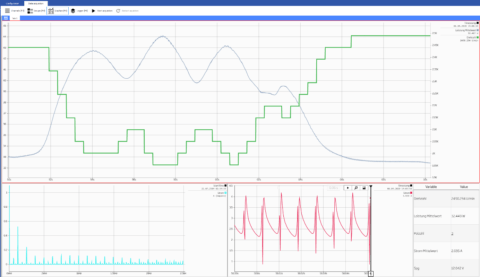

With GI.bench, you can create custom dashboards for visualization. Figure 4 shows the speed and power in the upper chart. When the motor is loaded, the speed decreases (green curve), while the power consumed increases (grey curve). Also, the current spectrum (blue), the current trace (red), and the parameters (table) are displayed numerically in this interface.

For references, demo programs and questions you can always contact us at info@gantner-instruments.com.

More articles

6 Tips for Stress-free Strain Measurement during Fatigue Testing of Aircraft Structures

Strain is the single most important measurement during aircraft fatigue testing. The accuracy and precision of strain gauge measurements is of the greatest importance to exactly determine the durability and damage tolerance of a structure. The higher a structure is in the ‘pyramid of test’, the higher the test complexity, number of measurement channels, and data produced. On top of that the risk in terms of time delay and cost associated to a test program increases more than proportional with the increase in test complexity. Here are six tips to help you choose the right data acquisition system for your fatigue test:

Read more...IPERMON – Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity

Currently, a vast amount of research institutions and organizations are focusing on ways to improve the operation, reliability and consequently the output of PV systems. An important aspect yet to be targeted remains the procedural and standardized approach to calculate accurately the factors behind the various performance loss mechanisms, while also detecting and diagnosing potential failures at early stages or before occurrence. Identification of degradation and failure modes at preliminary stages is important as these mechanisms directly influence the performance, lifetime and reliability of PV technology.

Read more...Gantner Instruments presents cryogenic measurement solution at Space Tech Expo

From October 24 -26 the Space Tech Expo and Conference took place in Bremen, Germany. The Space Tech is Europe’s meeting place for space business, Technology and innovation.

Read more...Measure the evolution of battery technology

New ground-breaking products and powerful solutions for fast and accurate Cell, Module and Pack testing

Read more...