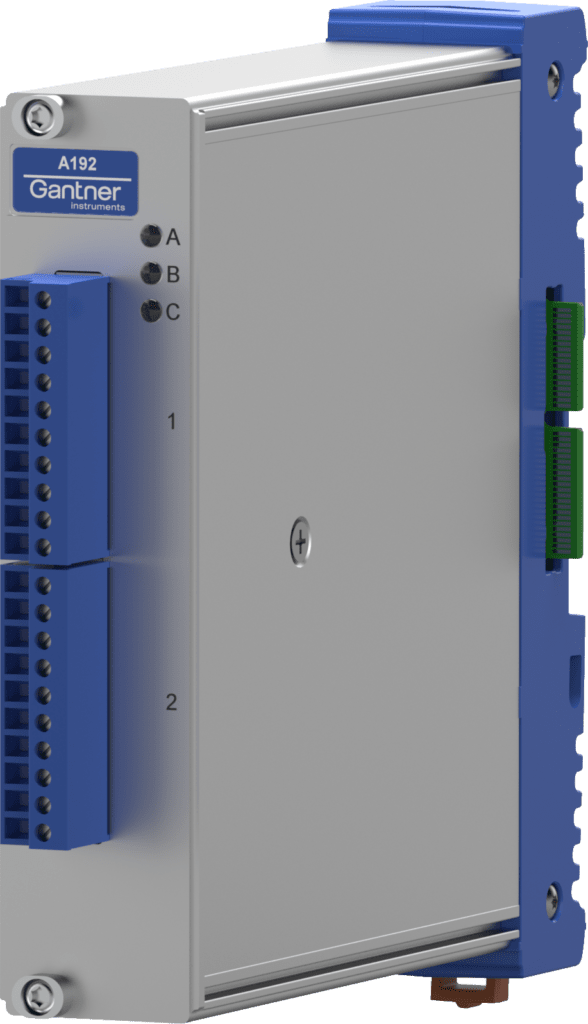

The Q.series X A192 is the newest, most flexible, and capable I/O module in the Q.series X product line. The A192 has been designed with critical (aero)space testing applications in mind, for instance static fire test of rocket engines, structural health monitoring, fatigue validation, and iron bird testing. The module’s universal analog input can be configured for either voltage, current, resistance, RTD, thermocouple, strain gage or IEPE measurement. To allow for greatest flexibility in selecting the appropriate sensors for your test bench, the A192 provides fully programmable transducer excitation in combination with an adjustable input range and amplifier gain (automatic).

Like any of the Q.series X modules, various communication busses are supported; Ethernet, EtherCAT and LocalBus. In addition, the A192 includes an analog output to share the measurement signal with, for example, a control command system or redundant data logger. The two onboard digital I/O channels are freely configurable and can be used to communicate status to the test bench emergency system. TEDS can be added to simplify system setup, self-check or for sensor traceability. And not least of all, the module comes with three-way galvanic isolation up to 500 VDC. All this makes the A192 the most versatile measurement module available for your mission-critical ground test applications.

Key Features:

- Multipurpose I/O module with 1-Ch at 100 kS/s with programmable Sensor Excitation and Analog Output

- Voltage ranges ±10 V, ±5 V, ±1 V, ±100 mV, ±10 mV

- Current range ±25 mA

- IEPE/ICP with programmable sensor excitation (1 mA to 12 mA in steps of 10 µA)

- Thermocouple

- Pt100/Pt100

- Resistance

- Strain Gage (quarter, half, full) with programmable sensor excitation (1 V to 12 V in steps of 1 mV, continuous short circuit proof)

- 1 Analog output channel

±10 VDC or ±22 mA - 2 Digital Inputs or Outputs

- Status, trigger, tare, alarm

- Standard 10-pole or customized input sockets

Find out more about our products here:

More articles

Webinar – Top Considerations for Selecting a Data Acquisition System for Testing Application

In today’s ever-changing technology environment, Test Engineers face bigger & more complex challenges than ever before when choosing a Future Proof, Robust & Expandable Data Acquisition System.

Read more...Innovation Call Vorarlberg 2023

Digital Innovation: Fueling the Future and Unveiling the Unseen

Read more...The 10 most important principles for effective acceleration measurement and vibration monitoring

In vibration monitoring and acceleration measurement, there are many variables to consider, and many opportunities to make mistakes. Sometimes it is nice to have a checklist that keeps you on the right track. Here are the 10 essentials for effective vibration monitoring and acceleration measurement

Read more...A Step Closer to Near-Supersonic Train Travel

South Korea’s hyperloop train reaches over 1,000 km/h in recent tests.

Read more...