EtherCAT was developed with industrial automation in mind, so finding EtherCAT-ready high-accuracy data acquisition devices which cover a wide range of sensors can be a challenge. Modern data acquisition system vendors such as Gantner Instruments offer a full range of measurement modules with a direct EtherCAT interface. There is no limitation in the type of sensors you can use within an EtherCAT-based data acquisition system: thermocouple, Pt100, LVDT, strain gage, IEPE/ICP©, piezoelectric (charge), high-voltage measurement up to 1200 VDC, and even fiber Bragg grating sensors.

Gantner Instruments provides you with robust I/O modules with the best-in-class accuracy, high stability, and minimal noise without long-term drift for all of the measurement types mentioned above. What do we mean by best-in-class accuracy?

Here are three examples:

- The margin of error for our A105 I/O module with four channels for RTD measurements is 0.05 K at a resolution of 100 µK.

- Our A108 I/O module brings eight channels of voltage or current measurements with an error margin of +/-2 mV for an input range of +/-10 V with a resolution of 1.5 µV.

- Our A116 I/O module can support eight inputs of quarter-, half-, and full-bridge strain-gages with an accuracy as low as 0.05 %.

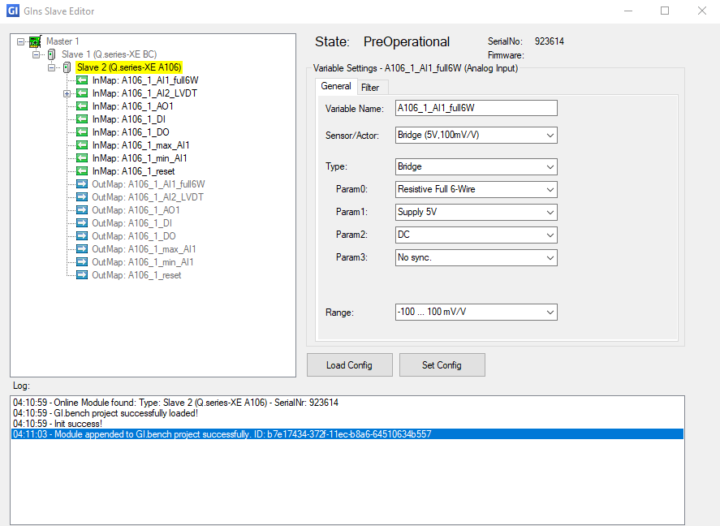

The Q.series X line of I/O modules is equpipped with pre-engineered signal conditioning functionality out-of-the-box. There is no need to program filters, linearization curves, or sensor scaling functions. With Gantner’s configuration software GI.bench, all configuration is done by mouse click, and also arithmetic functions like RMS, min., max., and average are set without any programming necessary. Suppose you choose a module that includes digital outputs. In that case, you can trigger an alarm output independent from any interaction with the master stack by defining a threshold directly on the I/O module.

Benefits in using our DAQ Platform

- Pre-engineered data acquisition functionality

- Out-of-the-box signal conditioning

- 20 continuous and triggered data loggers

- Significantly higher data rates

- Arithmetic, linearization and scaling functions

- No Sensor limitation

- Filtering onboard

- Alarm triggering

- 3-way 500 VDC galvanic isolation

Our Q.series X are in stock and we are able to deliver very fast.

Don’t miss this Chance and request a quote now!

Why Gantner Instruments DAQ modules make your life easier?

All Gantner Instruments I/O modules are fully compliant with the EtherCAT slave specifications from the EtherCAT Technology Group (ETG). Our I/O modules can connect with any EtherCAT master stack that follows these ETG specifications. To make integration with your master stack as simple as ABC, we provide various options for setting up our I/O modules in your EtherCAT master:

- EtherCAT Slave Information (ESI) file: With our GI.bench DAQ software, you can configure the I/O modules then easily export ESI files, which is the XML file used by many EtherCAT masters to configure slave devices and generate network description files.

- CoE online scan: The dynamic exchange of configuration settings between slave modules and the EtherCAT master using CAN Application Protocol over EtherCAT (CoE). This feature is supported by more advanced EtherCAT masters and offers extended flexibility between various hardware platforms all using EtherCAT.

- Direct EtherCAT master interface: Our GI.bench software offers the unique capability to interface with several EtherCAT master stacks to configure I/O modules directly via File Access over EtherCAT (FoE). This outstanding functionality is available for TwinCAT, the EC Master stack from Acontis, and the KPA master from koenig-pa GmbH.

Learn how Fraunhofer is using our DAQ platform in combination with TwinCAT

Discover how Fraunhofer Institute of Wind Energy Systems (IWES) aims to reduce the development costs and yield losses associated with operating 10+ MW wind turbines and why they chose Gantner Instruments DAQ for the job.

Is your EtherCAT master not listed here? Contact us to discuss the use of our DAQ hardware with your EtherCAT master stack!

More articles

FHV Jobmesse 2025

Gantner Instruments will be part of the largest job fair in the region on March 14, 2025.

Read more...Gantner Instruments presents new Machine Learning and Fault detection routines at leading PV and Energy conference in Brussels, Belgium

Within the EU founded project “IPERMON” (“Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity”) Gantner Instruments was developing different fault detection routines and failure classification methods for time series data sets.

Read more...Automotive Testing Expo Europe 2025

Join us at the Automotive Testing Expo in Stuttgart from May 20–22, 2025! Discover how our Q.series X DAQ systems and GI.bench software take your vehicle testing to the next level.

Read more...