As the world moves towards a greater reliance on renewable energies, the need for flexible solutions to balance energy supply and demand becomes crucial. One key technology that holds great potential in this regard is domestic heat pumps. Ongoing research explores how these heat pump systems and their thermal storage capabilities can be harnessed as flexible resources within the broader electrical energy system. Being an industrial partner within the Josef Ressel Centre for Intelligent Thermal Energy Systems at Vorarlberg University of Applied Sciences, Gantner Instruments drives innovation in the field of demand side management with heat pump systems, with a particular focus on enhancing performance and simplifying research processes. This article will delve deeper into the test rig used for research purposes [1], highlighting the sensor and actuator setup, control challenges, and the pivotal role played by GI.bench and GI.cloud in optimizing heat pump performance.

Test Rig Configuration

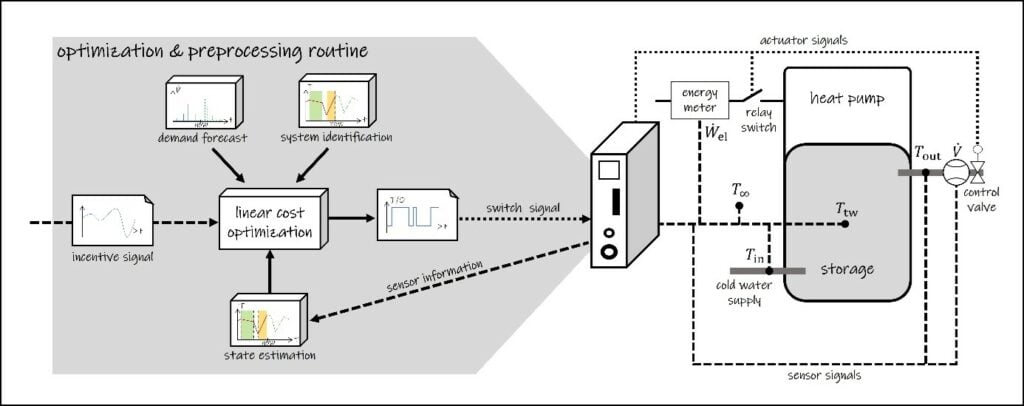

The test rig features an off-the-shelf 200-liter air-source hot water heat pump (HWHP). Equipped with a comprehensive sensor and actuator setup, the test rig allows for detailed data acquisition and control. K-Type thermocouples measure temperatures such as thermal well, water inlet, hot water outlet, and ambient temperature. Additionally, a power meter records electric power consumption, while a magnetic inductive flow meter measures the volume flow rate. Control of the hot water demand profile is achieved through a continuously controllable 2-way motor valve. All data acquisition and control tasks are seamlessly managed by the Gantner Instruments Q.station-XT.

Performance Increase for Researchers

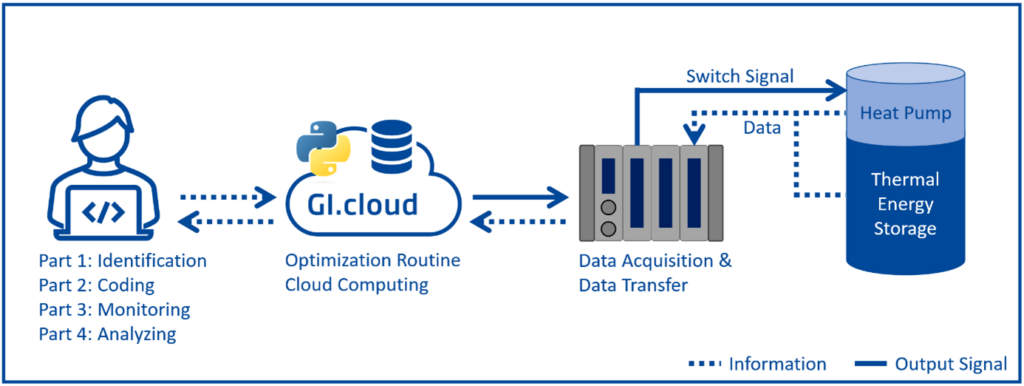

The simplicity of GI.bench and GI.cloud plays a vital role by enabling seamless data preprocessing in a lab setup. The GI.bench facilitates the connection of heat pump systems to GI.cloud, a centralized platform that empowers researchers to control the single heat pump unit. Developed using Python Jupyter notebooks, the software can be easily deployed on both the Q.station edge device and GI.cloud, creating a unified software ecosystem. This streamlined environment enables researchers to effortlessly perform data preprocessing, system identification, and state estimation. The user-friendly interface and intuitive workflows of GI.bench and GI.cloud free researchers from complex technicalities, empowering them to focus on their core research objectives.

The GI.cloud enables researchers to access and control the heat pump systems from anywhere. The Q.station edge device acts as a crucial bridge, facilitating seamless data transfer and control functionalities between the heat pump system and the GI.cloud. This connectivity infrastructure allows researchers to remotely monitor, analyze, and optimize heat pump schedules in real time. In the demo case, the optimization routine operated at 15-minute intervals, analyzing the data and predicting the best switching state for a prediction horizon of up to 24 hours. The average tank temperature is crucial for the decision process, thus, it has to be calculated using state estimation prior to optimization. Once the optimization is complete, the calculated solution is executed in real time as signal via the Q.station’s output ports to efficiently control the heat pump unit according to the desired parameters. This approach ensures optimal performance and energy utilization for the heat pump system. You can find more about this in the open-access publication by Baumann et al. [1], which was also featured in Advances in Engineering.

Conclusion

The collaboration between Gantner Instruments and the Josef Ressel Centre helps to transform research in intelligent thermal energy systems. By leveraging the power of GI.bench and GI.cloud, researchers enhance their performance, simplify workflows, are able to extract valuable insights and improve the flexibility and efficiency of domestic heat pumps as flexible resources. The user-friendly interfaces, seamless connectivity, and comprehensive data preprocessing capabilities offered by GI.bench and GI.cloud enable researchers to unlock the full potential of heat pump systems for demand side management. Thereby, the partnership enables research necessary for the transition towards a sustainable energy system to be faster and more efficient.

[1] C. Baumann, G. Huber, J. Alavanja, M. Preißinger, P. Kepplinger, Experimental validation of a state-of-the-art model predictive control approach for demand side management with a hot water heat pump, Energy and Buildings 285 (2023) 112923.doi:10.1016/j.enbuild.2023.112923.

More articles

GI.basic Training in NRW

GI.basic training near you: we will be in NRW on May 16, 2024

Read more...8 Tips to Consider When Buying a Strain Gage Amplifier

The strain gage is one of the most important tools of the electrical measurement technique applied to the measurement of mechanical quantities. As their name indicates, they are used for the measurement of strain.

Read more...Q.series X D107 SV: Digital Measurement Module with Sensor Supply

The Q.series X D107 2 x Lemo 2B SV module from Gantner Instruments provides a comprehensive solution for digital signal acquisition and sensor supply needs. Designed for distributed installations requiring precise digital measurements, this module enhances the Q.series product family's robust offering.

Read more...Webinar – Crate.io + Gantner Instruments: Real-time energy grid control based on big data

With the increase in renewable energy sources, the challenge for electric grid operators to keep grid frequencies stable has become even more significant. Constant data collection is essential for modern control technology and makes it possible to execute controls more quickly, whereby the use of smart grids can be further optimized.

Read more...