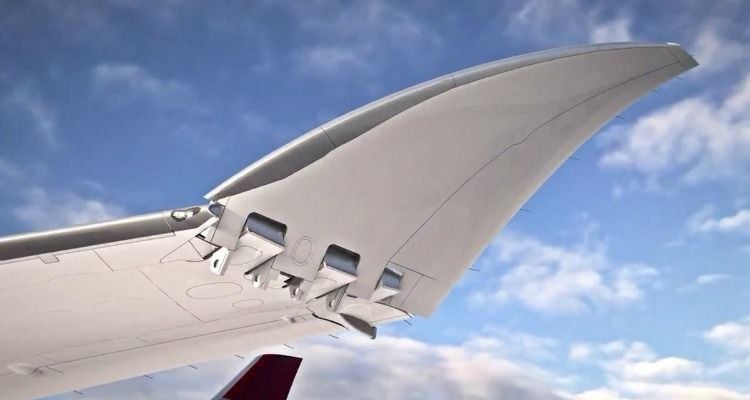

Boeing credits much of the 777X’s improved fuel efficiency to the aircraft’s composite wings, which stretch 71.8m (236ft) from wingtip to wingtip. To make sure that the 777X will fit in existing airport gates, the wingtips will be able to fold upward by 3.5m on each side.

Liebherr-Aerospace has been selected to design, develop, and manufacture the folding wing tip system. With its motor and rotating actuator, this system will fold the wing tip after landing, thus reducing the wingspan of the new wide-body aircraft by 7 meters. The folding wingtip system is the first of its kind in commercial aviation, so extensive testing is required. Not only to ensure passenger convenience (passengers should actually not hear loud noises or significantly feel the action of the mechanics), but also from a safety perspective. Failures or external threats must not compromise both primary and backup systems simultaneously. A wingtip failure will ground the aircraft!

For this critical test program Liebherr-Aerospace uses a Gantner Instruments Q.series system to perform the primary data acquisition tasks. The flexibility of the Q.series system, in combination with a wide variety of commercial off-the-shelf I/O modules, allows Liebherr-Aerospace to maximize test equipment utilization, test bench availability and overall test lab performance. On top of that, the Q.series measurement system features a set of specific features that are crucial for successful aircraft component testing. So does the Q.series system come with precise nanosecond time synchronization between all modules and to external time references, eliminating the uncertainty of data skew during critical test conditions.

The build-in test automation functionality enables quick and efficient monitoring and processing of measurement data, minimizing manual system handling and shortening overall test duration time. And last but not least, the Q.series system has 3 levels of redundancy for assured data availability. Measurement data can be transferred to 2 data storage locations simultaneously and 1 data location for backup.

More Information

Click here to receive a personalized Application Example Pack containing the real-world application example “Boeing 777X Folding Wingtip System Test” and a few bonus application examples within the Aerospace industry!

More articles

Gantner Instruments TechDay

On April 28, 2026, Gantner Instruments invites you to the GI TechDay DACH 2026 at their headquarters in Schruns, Austria. Join this free event focused on testing and inspecting electric drives, batteries, and fuel cells.

Read more...Python Integration – A New Level of Automation and Analysis

Engineering teams rely on powerful, customizable tools to handle increasingly complex test scenarios. GI.bench now includes integrated Python scripting, empowering engineers to automate measurement workflows, perform advanced real-time analyses, and seamlessly integrate with external software. This feature leverages Python's rich ecosystem, ensuring flexibility and efficiency in test and measurement projects.

Read more...Q.series X A192

The Multifunction Module when Flexibility and the Highest Performance Matters Most

Read more...Webinar – Top Considerations for Selecting a Data Acquisition System for Testing Application

In today’s ever-changing technology environment, Test Engineers face bigger & more complex challenges than ever before when choosing a Future Proof, Robust & Expandable Data Acquisition System.

Read more...