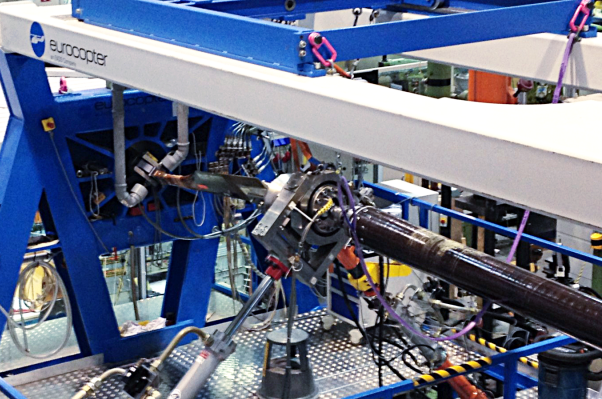

Typical test applications that are performed by component structural testing lab are blade fatigue testing, rotor hub endurance testing, and full-scale airframe testing. The legacy control and data acquisition system used by Airbus Helicopter, called “AMOS”, is a comprehensive and proprietary concept used across all their test rigs. The system offers extensive functionality and flexibility, nevertheless is expensive to maintain and difficult to upgrade to meet today’s demanding test requirements.

The new control and data acquisition system had to maintain the functionality and flexibility that Airbus is accustomed to, whilst introducing state-of-the-art hardware and software technology. A challenging assignment. Many well-known control and data acquisition system vendors presented their latest solutions. After a long and intensive evaluation, considering all technical and commercial aspects, Gantner Instruments was selected as supplier of choice for the Airbus’ new control and data acquisition system solution.

“We chose the best, most modern and most flexible concept for our next generation Control and DAQ system. For this project we chose Gantner Instruments.”

-Sr. Test Engineer Airbus Helicopters

The heart of the Gantner Instruments’ supplied control and data acquisition system is the Q.raxx EC A106 I/O module in a 19″ rack enclosure. Key features of the Q.raxx EC include; distributed clock for data synchronization (ETG.1020.0), File access over EtherCAT (ETG.1000.5), CAN over EtherCAT ( ETG.5001.1), oversampling technology for data rates up to 100 kHz, and configurable PDO mapping to optimize the data throughput.

The Q.raxx EC ensures that both control and measurement system work together on one fieldbus, eliminating the uncertainty of data skew during critical test conditions. Gantner Instruments’ Q.raxx EC sets the standard for data acquisition performance and flexibility – meeting, and exceeding, the most demanding test system specifications set by Airbus Helicopters.

More articles

Integrated Video and Data Logging – Enhanced Context and Analytical Depth with GI.bench

When analyzing measurement data, numbers alone often leave unanswered questions, particularly during unexpected events. GI.bench solves this challenge by integrating synchronized video recording directly with your measurement data, providing powerful visual context and significantly enhancing analytical clarity.

Read more...PowerUp EV: Virtual Business Meet on EV Technology

Join us for PowerUp EV, a virtual business meet dedicated to exploring the latest advancements and trends in Electric Vehicle (EV) technology. Organized by Smart Energy Magazine the event is cosponsored by Gantner Instruments, a leading provider of testing solutions for the automotive industry, this event aims to bring together experts, professionals, and enthusiasts in the EV sector for insightful discussions and networking opportunities.

Read more...Gantner Instruments delivers DAQ system to the Technical University of Denmark – DTU

Gantner Instruments is proud to announce that is has delivered it’s Q.series Data Acquisition System to the Technical University of Denmark (DTU) for their Villum Center for Advanced Structural and Material Testing (CASMaT). The center is a collaboration between DTU Civil Engineering, DTU Mechanical Engineering and DTU Wind Energy with the objective to strengthen experimental research in mechanics of structures and materials. A large donation from VILLUM FONDEN made it possible to establish the center.

Read more...Empowering Researchers: Simplifying Research and Enhancing Performance with GI.bench and GI.cloud

Discover how Gantner Instruments enhances heat pump performance and streamlines research, driving innovation in renewable energy and demand side management.

Read more...