As the demand for hydrogen-powered systems grows, so too does the need for precise measurement technology in extreme environments. Hydrogen technologies often operate at cryogenic temperatures, where precision and reliability are critical for ensuring safe and efficient performance. Gantner Instruments is proud to offer state-of-the-art cryogenic measurement solutions, including our Q.bloxx A105 CR Module, designed specifically for applications in hydrogen production, storage, and fuel cells.

Cryogenic Precision with the Q.bloxx A105 CR

The Q.bloxx A105 CR Module is designed to provide highly accurate temperature measurements at cryogenic levels, ideal for use in hydrogen-powered engines and liquefied hydrogen storage systems. Featuring 4 galvanically isolated input channels, it supports popular cryogenic sensor types such as Cernox® and TVO, with selectable ranges up to 25 kΩ, which makes the module adaptable for use with a variety of cryogenic sensors, which is essential in the fast-growing hydrogen sector.

Key features of the A105 CR Module include:

- 7.5 µA sensor excitation: Minimizes sensor self-heating to reduce measurement errors, which is critical in maintaining accuracy at cryogenic temperatures.

- High-accuracy digitalization with a 24-bit ADC: Ensures stable, precise readings even in rapidly changing environments, with a sample rate of 10 Hz per channel.

- Sensor-specific linearization: Up to 32 calibration points allow for precise compensation of non-linearity in cryogenic temperature sensors, providing long-term stability and accuracy across various hydrogen applications.

Advanced Solutions for Hydrogen Storage Systems

Hydrogen storage and transport systems, especially those operating with liquefied hydrogen, are susceptible to extreme temperature variations. The Q.bloxx A105 CR Module ensures stable and accurate temperature readings, which are essential for optimizing storage conditions, preventing boil-off losses, and ensuring the structural integrity of hydrogen containment vessels. The module can handle high-resistance sensors and support extended measurement ranges, making it ideal for emerging applications where new sensor technologies are rapidly evolving.

For hydrogen vessel testing, the A105 CR supports continuous monitoring of the temperature within critical components, enabling real-time adjustments to maintain optimal operating conditions. The module’s precise measurements help prevent performance degradation due to thermal stress or uneven heat distribution in the system.

Maximizing Efficiency in Cryogenic Hydrogen Testing

Gantner Instruments’ cryogenic measurement solutions help push the boundaries of innovation in hydrogen technology. By ensuring long-term measurement stability and reducing sensor self-heating, our modules provide the reliability required for hydrogen storage, fuel cell development, and cryogenic engine performance. Whether integrated into R&D projects or full-scale industrial applications, the Q.bloxx A105 CR Module delivers the precision necessary to support the future of hydrogen energy.

The Q.bloxx A105 CR Module is just one of the advanced measurement modules that can be integrated into the Q.series X system for a complete characterization of thermal, mechanical, and electrical working conditions in extreme environments with extreme accuracy.

Proven Expertise in Cryogenic Hydrogen Applications

Gantner Instruments has a strong track record of providing advanced measurement solutions for complex cryogenic applications, including significant projects in nuclear fusion research and hydrogen energy systems. Our ability to deliver precise, reliable, and customizable data acquisition systems has led to our selection for several demanding projects.

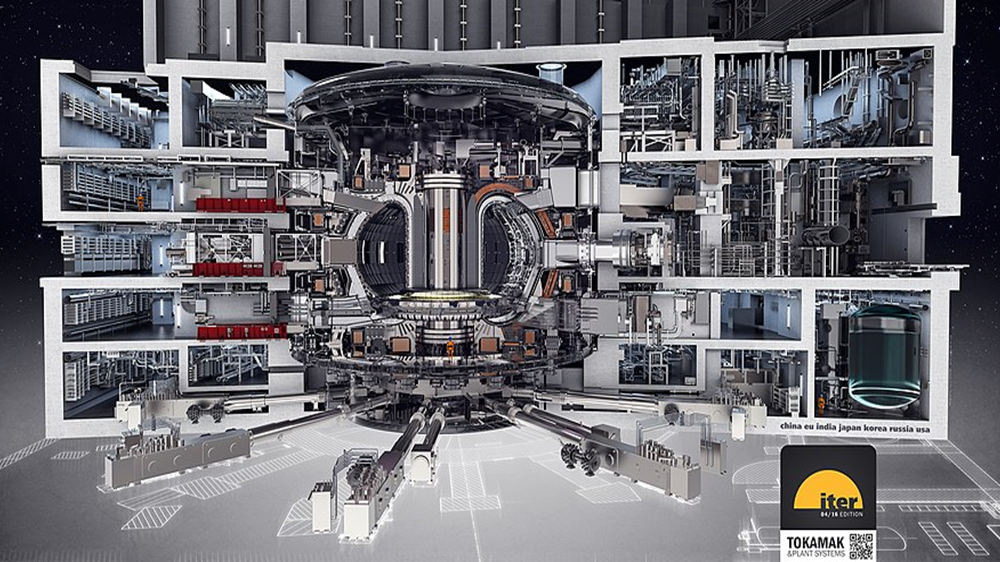

ITER Cryogenic System Monitoring

Reason for Selection: Our capability to deliver highly accurate temperature measurements at cryogenic levels, combined with custom solutions to mitigate magnetic field interference, made us the preferred choice for ITER’s critical monitoring needs. The Q.bloxx A105 CR module’s low excitation current minimized sensor self-heating, ensuring precise measurements essential for maintaining the superconducting magnets at temperatures as low as 2–3 K.

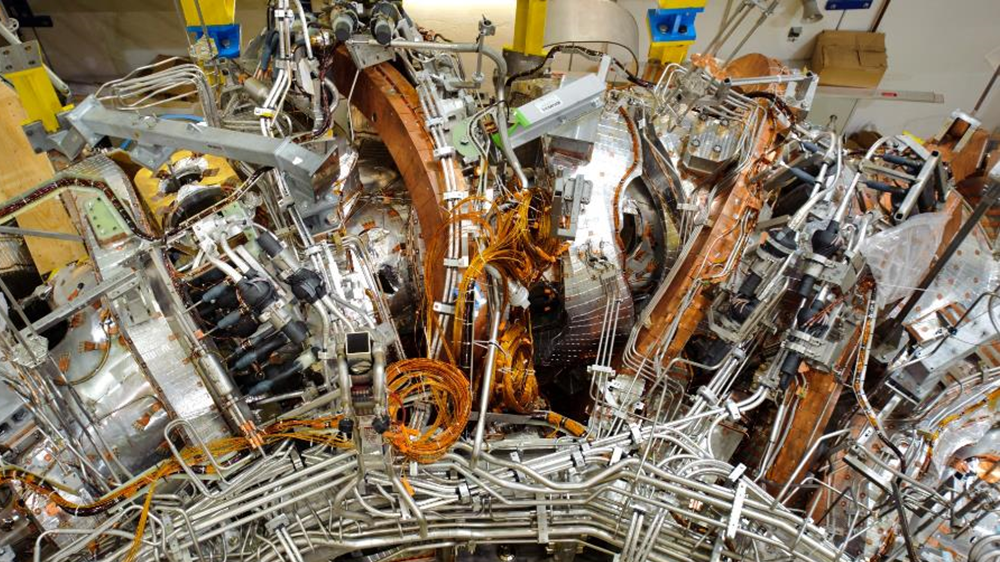

Wendelstein 7-X Fusion Reactor Monitoring by Max Planck Institute for Plasma Physics (IPP)

Reason for Selection: The project’s requirements included precise measurements across a wide temperature range, resistance to strong magnetic fields, and minimal sensor self-heating. Our intermittent measuring modes reduced power to the sensors, minimizing self-heating and thermal voltages, which was crucial for accurate measurements in the challenging environment of a fusion reactor.

More articles

Overcoming Challenges in Building Safe and Efficient Test Benches with test.con

Addressing Critical Obstacles in Test Bench Development

Developing test benches that comply with stringent safety standards and regulatory requirements is unavoidable in industries like automotive, energy, and medical technology. However, this process presents unique challenges, including navigating complex compliance landscapes, integrating diverse systems, managing operational risks, and ensuring thorough documentation. Below, we examine these challenges and demonstrate how Gantner Instruments' test.con software can effectively address them.

Wendelstein 7-X Stellarator

After 9 years in construction, the stellarator (nuclear-fusion machine) of the Max Planck Institute in Greifswald generated plasma for the first time on December 10, 2015. The reactor had been gradually ramped up over the past 12 months. The event was given extensive coverage in the media. Gantner Instruments specially developed sensors for temperature and strain measurement for the project, which are otherwise unavailable on the market.

Read more...PV & Grid Integration Symposium

Meet us at the 2019 PV Systems Symposium, the leading industry get together for PV Monitoring and grid integration in Albuquerque (New Mexico), United States.

Read more...Q.series X A101 SV: Universal Measurement Module with Sensor Supply

The Q.series X A101 2 x DB15HD SV module from Gantner Instruments is a precisely engineered multi-functional measurement module that seamlessly integrates into a variety of industrial applications. With 2 universal analog inputs and a programmable sensor supply voltage and current limit, this module is crafted to provide precise and reliable data across a spectrum of measurement needs.

Read more...