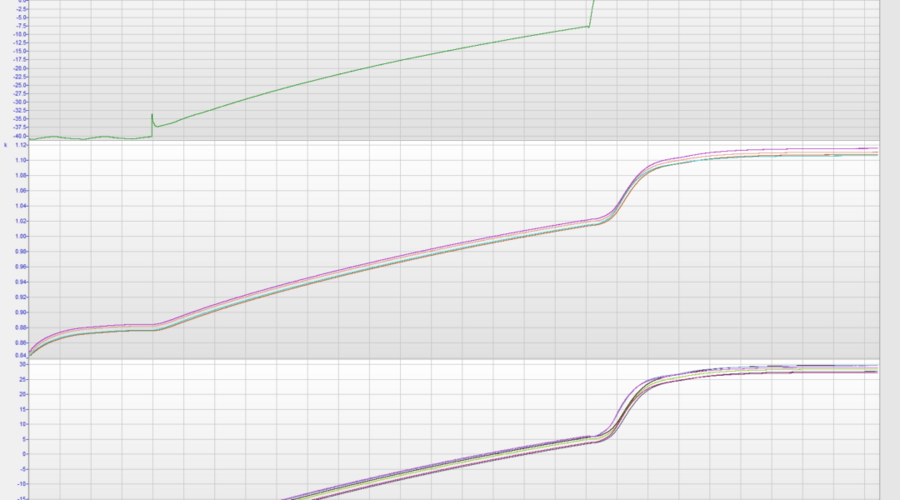

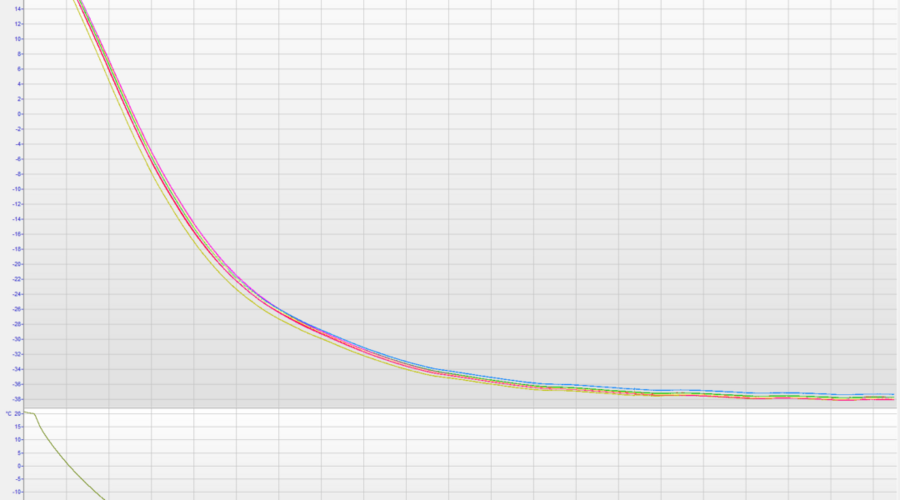

The Q.bloxx XL A104 TCK provides 8 channels for thermocouples (here as Type K, NiCr/Ni) with standard miniature front sockets.

During a day in the climate chamber at -40°C it was completely frozen. After connecting with power supply to the I/O module it was delivering stable and precise measurement values. When temperature was increasing it passed dew point. We observed no impact on the measurement quality or from condensation during this phase. Our I/O module passed this test successfully – even when the datasheet recommends only -20°C operating conditions.

More articles

Q.series X D101 SV: Digital Measurement Module with Sensor Supply

The Q.series X D101 4 x Lemo 2B SV from Gantner Instruments is a digital measurement module that has been engineered to facilitate a broad spectrum of digital signal processing tasks. It is designed with a focus on providing accurate and rapid data acquisition for industrial applications that require high-performance measurement capabilities with integrated sensor excitation.

Read more...Daily Meals for 300 Children

After establishing our company last year in India, we became aware of the Sri Karpagavalli Vidyalays Middle School, a school for 300 girls and boys ages 5 through 14. Not only do these children, coming primarily from the slums, lack educational material, they frequently do not even have elementary necessities like food.

Read more...Wendelstein 7-X Stellarator

After 9 years in construction, the stellarator (nuclear-fusion machine) of the Max Planck Institute in Greifswald generated plasma for the first time on December 10, 2015. The reactor had been gradually ramped up over the past 12 months. The event was given extensive coverage in the media. Gantner Instruments specially developed sensors for temperature and strain measurement for the project, which are otherwise unavailable on the market.

Read more...Dynamic High Voltage Measurement: Q.series X A128 Plus SEB

Gantner Instruments introduces the Q.series X A128 Plus SEB, a dynamic high-voltage data acquisition solution.

Read more...