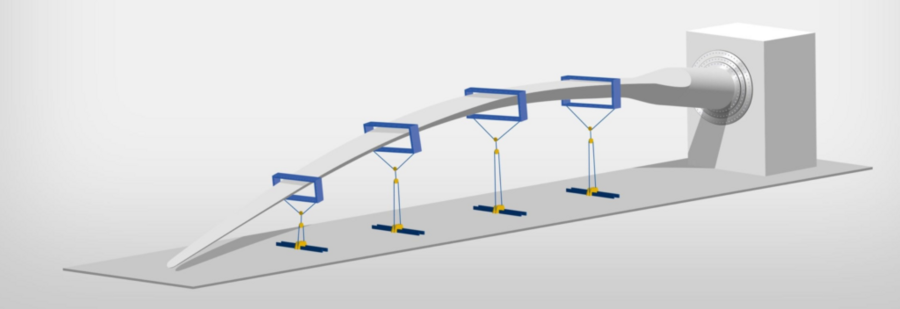

As the size of wind turbines whose blades will soon exceed the 100 m mark and generate power of up to 8 MW, the question of the material (composites) and its strength is an ongoing issue. The Danish Test Center BLAEST in Aalborg has specialized in the testing of components of wind turbines.

The test center BLAEST, owned by the leading wind technology institutes Force Technology, Technical University of Denmark (DTU – Risø) and Det Norske Veritas DNV Germanischer Lloyd – GL operates several test stands for strength and fatigue testing of rotor blades.

The prototype of each rotor blade has to be tested before approval, and series production on its strength. These tests are carried out in accordance with IEC 61400-23. BLAEST is certified for the complete test.

Read on this topic, our cover story in the issue 03/2016 of the journal mpa here!

More articles

Python Integration – A New Level of Automation and Analysis

Engineering teams rely on powerful, customizable tools to handle increasingly complex test scenarios. GI.bench now includes integrated Python scripting, empowering engineers to automate measurement workflows, perform advanced real-time analyses, and seamlessly integrate with external software. This feature leverages Python's rich ecosystem, ensuring flexibility and efficiency in test and measurement projects.

Read more...3 ways advanced DAQ solutions help the aviation industry transition to a sustainable future

By 2050 we need to become a carbon-neutral society, and the aviation sector needs to contribute. While flying less can help reduce emissions, we have options for cleaner air travel. For one, we could power our flight with electricity or hydrogen, which are no longer ideas in some futuristic science fiction novel. Rather, they are on the brink of generating a shift in aviation technology.

Read more...Strain Measurements on Flexible Pipeline Systems

NOV in Denmark tests flexible pipeline systems with the Gantner Instruments Q.bloxx modules.

Read more...What is Electrochemical Impedance Spectroscopy (EIS)?

As society shifts towards clean, renewable energy, batteries and hydrogen technologies are becoming increasingly crucial. Electrochemical Impedance Spectroscopy (EIS) offers researchers and engineers valuable insights into these technologies' inner workings. In this blog post, we will explore EIS's benefits, its integration with Q.series X, and its application to batteries and hydrogen technologies.

Read more...