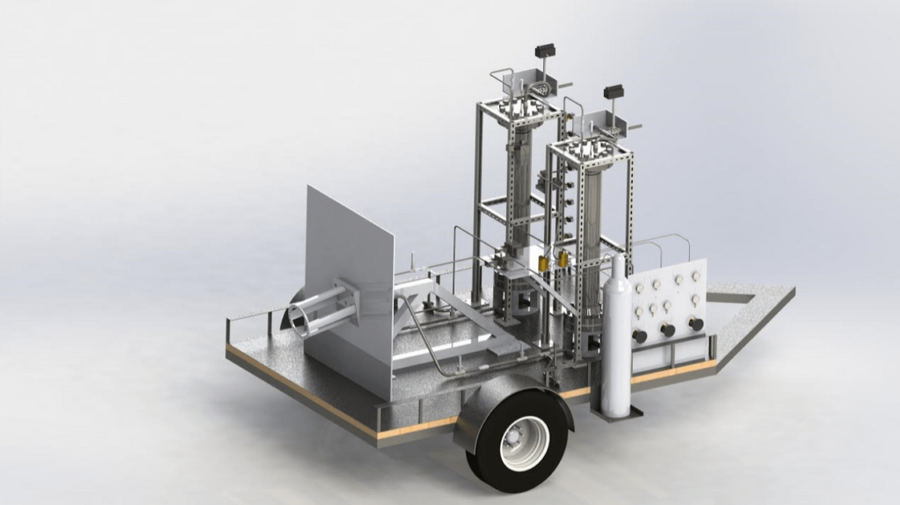

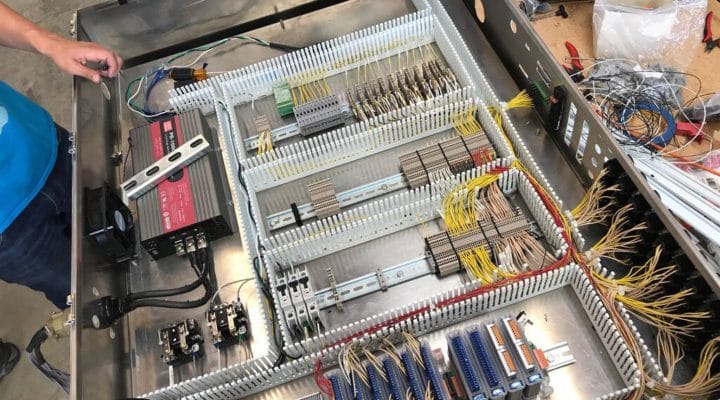

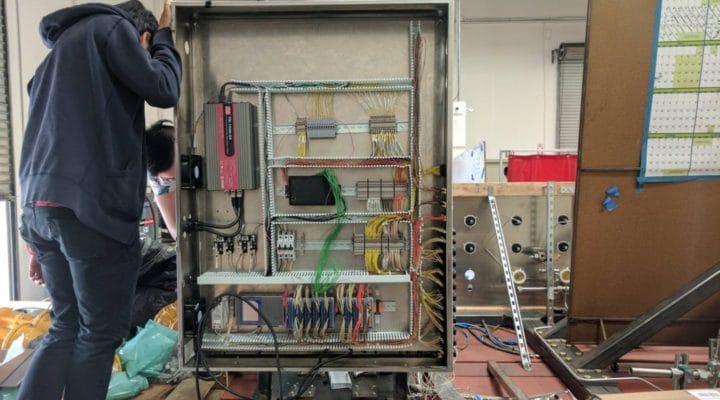

The Gantner Instruments DAQ system is designed to receive signals from the test stand’s sensors and send reports back to the operator for monitoring and control. The Q.station controller is being programmed to automatically respond to errors and actuate fire safety valves to prevent System failures.

Construction recently began on the test stand by the SEDS software and electronics team. Gantner Instruments Technical Support team provided training on the use of the hardware and software and help with the initial configuration of the test stand DAQ system.

We will post more updates as construction continues on the Colossus project!

More information about the project can be found here:

More articles

Strain Measurements on Flexible Pipeline Systems

NOV in Denmark tests flexible pipeline systems with the Gantner Instruments Q.bloxx modules.

Read more...Turbomeca Chooses the Q.series

Turbomeca is a french manufacturer of compressors and turbines for the aviation industry, among its customers Eurocopter, Augusta und Sikorsky. For the test and measurement design of future test stands were the products from four manufacturers tested, and the companies rated on quality in production, and in all functional processes. Turbomeca selects Gantner Instruments GmbH as manufacturer and accredited according to strict rules. Gantner Instruments is exclusively represented by BGP Electronic in France.

Read more...3 ways advanced DAQ solutions help the aviation industry transition to a sustainable future

By 2050 we need to become a carbon-neutral society, and the aviation sector needs to contribute. While flying less can help reduce emissions, we have options for cleaner air travel. For one, we could power our flight with electricity or hydrogen, which are no longer ideas in some futuristic science fiction novel. Rather, they are on the brink of generating a shift in aviation technology.

Read more...New Monitoring Solution – Q.series Portable

For short-term or rout-based condition monitoring of various assets we now provide a portable system solution. Our new Q.series Portable based on Q.station 101 and OEM-boards for analog and digital inputs contained in a robust transport case is fully engineered and ready to use ‘out of the box’. The electronic boards and the power supply system are mounted on shock absorbers to withstand heavy-duty work under harsh environments in the field.

Read more...