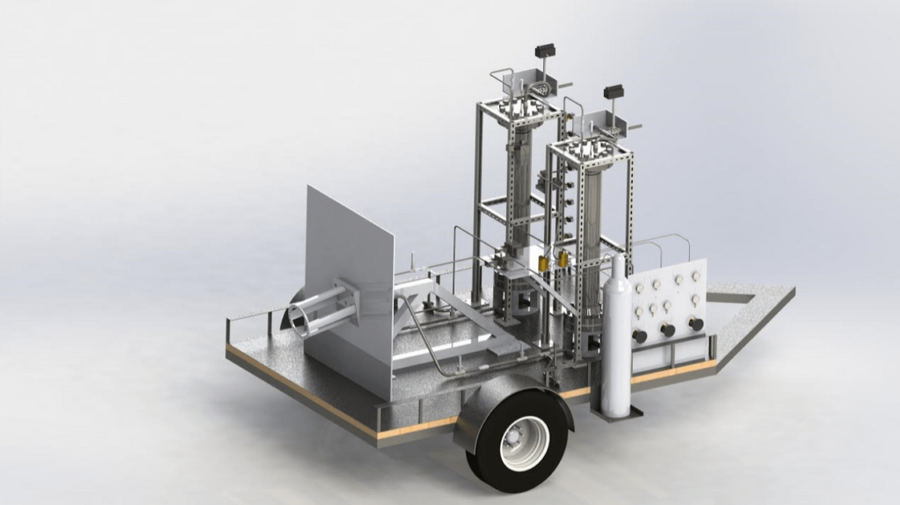

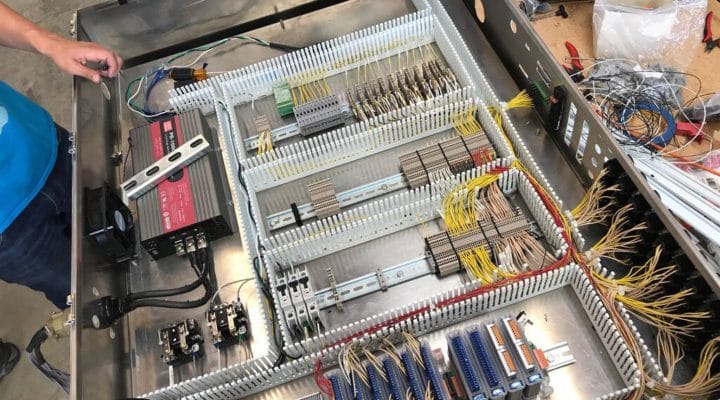

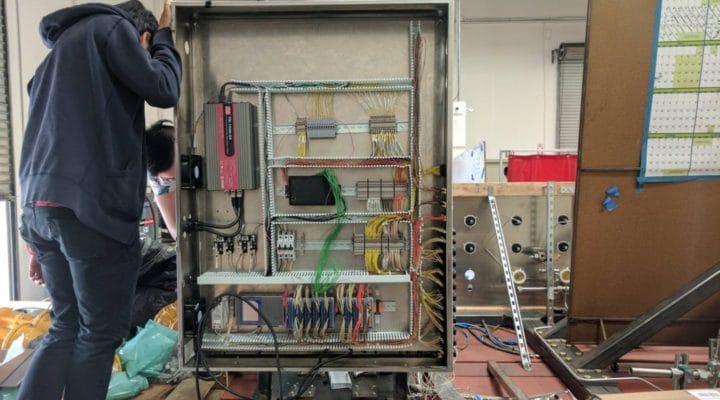

The Gantner Instruments DAQ system is designed to receive signals from the test stand’s sensors and send reports back to the operator for monitoring and control. The Q.station controller is being programmed to automatically respond to errors and actuate fire safety valves to prevent System failures.

Construction recently began on the test stand by the SEDS software and electronics team. Gantner Instruments Technical Support team provided training on the use of the hardware and software and help with the initial configuration of the test stand DAQ system.

We will post more updates as construction continues on the Colossus project!

More information about the project can be found here:

More articles

Precise Measurement of High Voltage Systems

In high-voltage environments, the precision and reliability of measurement systems are crucial for safety, compliance, and performance optimization. High-voltage testing and measurement are integral to developing and producing equipment and systems that operate under high-voltage conditions, such as power transmission systems, high-voltage motors and generators, and components for electric vehicles. Gantner Instruments' Q.series X A12x modules (e.g., Q.series X A128) offer sophisticated solutions to address the unique challenges of high-voltage measurements.

Read more...Q.bloxx A105 CR Cryo Module with Extended Range

Cryo Technology is a rapidly growing market and therefore more and more new sensor kinds appear. A clear trend is that these cryogenic temperature sensors move to higher resistance. With Gantner’s cryo module – the Q.bloxx A105 CR – a measurement range of up to 25kohms is now possible. The module is available as standard DIN rail module, or as Q.brixx/Q.raxx with 4 times 4-pole-LEMO (ERA.1S.304.CLL).

Read more...GDevCon 4 Glasgow

Immerse yourself in the vibrant world of graphical programming at GDevCon 2023 on the 20th and 21st of September, from 9:00 am - 6:00 pm, at the esteemed Glasgow Science Centre, Scotland. This conference is a must-attend event for anyone striving to push the boundaries in the fields of engineering and technology.

Read more...Q.series X A142

Universal I/O module with analog output for closed-loop control applications

Read more...