In the following examples of applications, our products are being used with great success:

MAHLE Behr

Development and testing of air conditioning components for the automobile industry. The extremely high demands for efficiency make it necessary when measuring heat levels to ensure a very precise recording of temperatures. For this reason, our modules have been employed in this area for several years.

German Weather Service (DWD)

The weather stations installed throughout the country have to deliver reliable measurement values at all extremes of external temperature. Whether in the winter in the Alps or in the summer at the seaside, Gantner modules are used by the DWD to produce accurate measurements, whatever the ambient temperature.

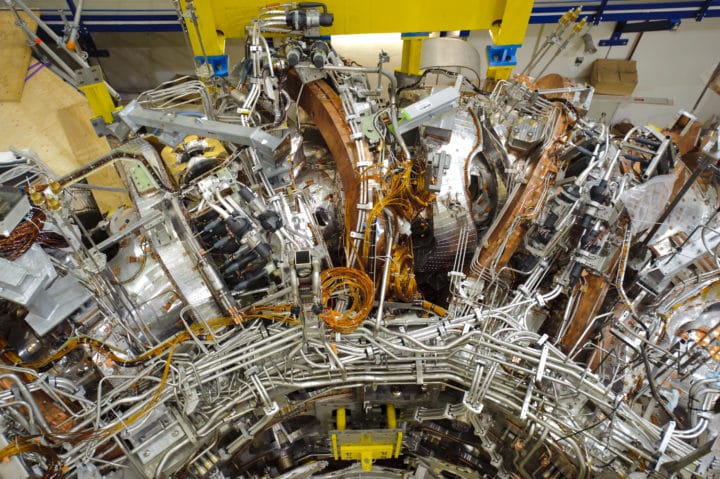

Max-Planck-Gesellschaft, Institute for Plasma Physics

The development of the fusion facility Wendelstein 7X would be impossible without reliable and precise temperature recording. Our modules are also used in this project, as there are no comparable alternatives on the market.

The following are the most important characteristics of the module A105, which is available as Q.bloxx for top hat rail mounting, as a mobile system Q.brixx or in a 19″ version:

- 4 galvanically separated input channels for Pt100, Pt1000 and for resistance measurement

- Measurement precision

0.05 °C - Temperature stability

0.02 °C per 10 °K change

in ambient temperature - Analog/digital conversion

24 bit - Filter, linearization, min/max and alarm independently configurable for each channel

- Versions can be provided for special sensors, for example cryosensors (TVO, Cernox)

More articles

Gantner on expansion course

In 2014 Gantner Instruments GmbH moved into its new, energy-efficient company building in Schruns. The modern building with an area of 1000 m² has been designed from the beginning to offer the possibility of extension. This option was used in 2017 by the company, which has a steady double-digit growth per year since its inception.

Read more...Test of Battery and Battery Management Systems

At a very early stage Gantner Instruments was involved with special products for testing of batteries in the E-Drive environment. An already existing and successful product range is now supplemented with a useful novelty.

Read more...Introducing GI.bench – Enhanced DAQ Capabilities for Engineering Excellence

Engineers and technicians often have a lot of problems when they are dealing with complicated data acquisition setups. These setups can include large amounts of data, the use of different devices, and the need for information in real time. Addressing these challenges head-on, Gantner Instruments proudly announces the latest evolution of our industry-leading software, GI.bench.

Read more...What is Electrochemical Impedance Spectroscopy (EIS)?

As society shifts towards clean, renewable energy, batteries and hydrogen technologies are becoming increasingly crucial. Electrochemical Impedance Spectroscopy (EIS) offers researchers and engineers valuable insights into these technologies' inner workings. In this blog post, we will explore EIS's benefits, its integration with Q.series X, and its application to batteries and hydrogen technologies.

Read more...