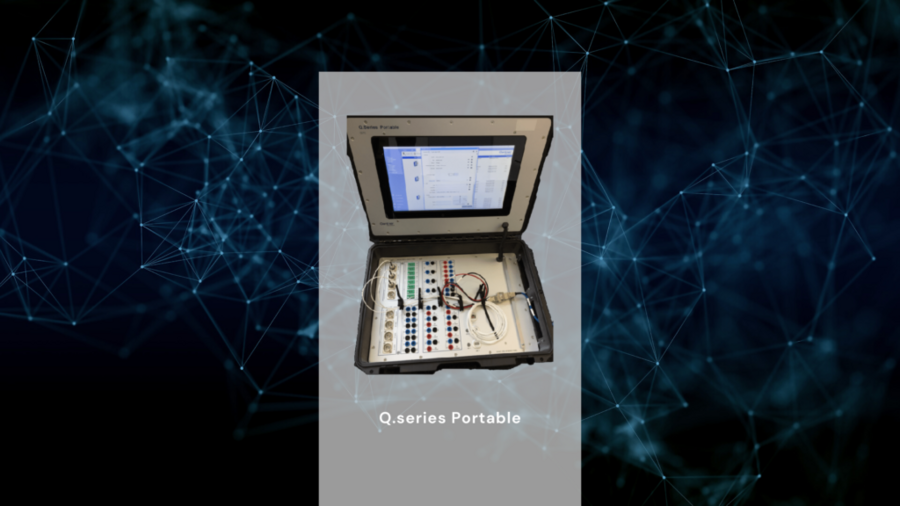

The Q.series Portable is available in two versions:

- Q.series Portable – Standard with up to 32 user defined channels

- Q.series Portable – Extended with up to 64 user defined channels and inbuild touch Display

Both versions have inbuild storage device extendable with USB drives and can be extended by further modules e.g. Q.staxx on two UARTS. With customized plugs and sockets for sensor connection and inbuild sensor excitation for example for MEMS sensors the system is ready to use after very short installation time. With special cable entries sensor cables with installed plugs can be inserted into the transport case while providing an IP protection grade of IP54 / IP63 (depending on type of cable entry).

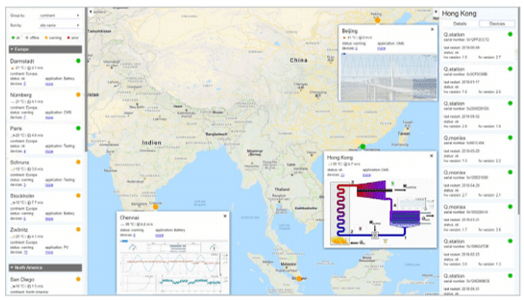

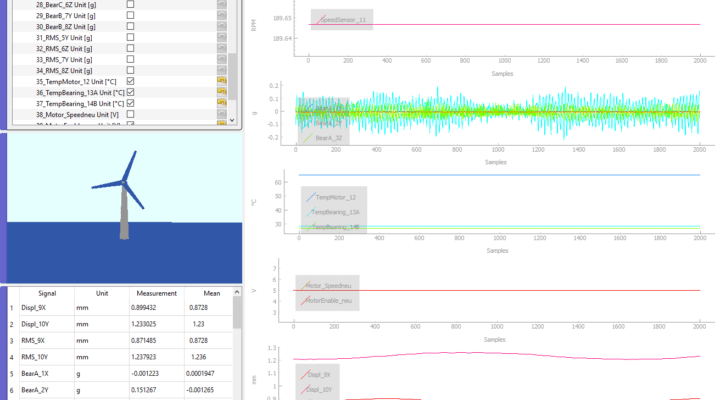

The Q.series Portable can be installed close to a machine, equipment, plant, etc. or extended across a large area with daisy chained additional modules. Connectable and networkable by Ethernet to other Gantner DAQ systems or remote computers for data visualization, data can be internally logged with inbuild storage or accessible USB drive ports. With the OPC UA interface of the Q.station also an online connection to SCADA systems is possible. 4G/LTE Modem for automated data transfer to customer host or GI.cloud can be ordered as an option.

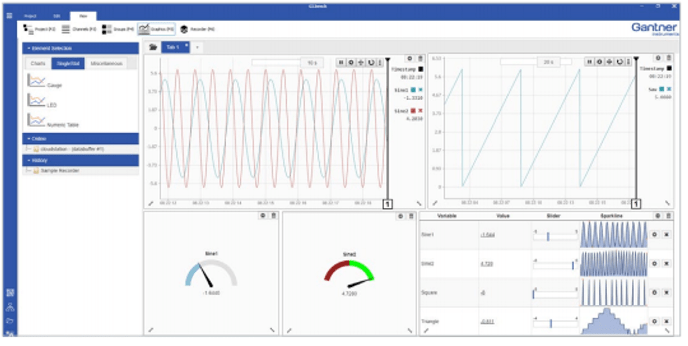

With the different interfaces you have the choice to use it as a stand-alone data logger or visualize the live data on GI.bench, GI.cloud or with a customized user interface made with Python.

For more information about the Q.series Portable you can check out the flyer:

More articles

Wünderla ko

“Wünderla ko" on September 16, 2023 from 10 am - 4 pm along Montafonerstrasse 4-21 in Schruns.

Read more...Precise Measurement of High Voltage Systems

In high-voltage environments, the precision and reliability of measurement systems are crucial for safety, compliance, and performance optimization. High-voltage testing and measurement are integral to developing and producing equipment and systems that operate under high-voltage conditions, such as power transmission systems, high-voltage motors and generators, and components for electric vehicles. Gantner Instruments' Q.series X A12x modules (e.g., Q.series X A128) offer sophisticated solutions to address the unique challenges of high-voltage measurements.

Read more...Real-world High-Power EIS Measurements – Free Webinar

Gantner Instruments invites experts and decision-makers from manufacturing companies and asset management to our focused webinar on “Real-world High-Power EIS Measurements.”

Read more...Innovation in Alpine Solar: Overcoming Winter Energy Challenges

Switzerland is investing in the untapped potential of Alpine photovoltaic (PV) generation and making strides toward a sustainable future. This blog explores the innovative Sedrun Solar project, a pioneering high-altitude PV initiative to fill the winter energy gap. Uncover how rigorous testing and insightful data collection, facilitated by Gantner Instruments, are paving the way for optimizing this renewable energy source.

Read more...