Due to its large size, the maintenance services are divided into strategic areas to serve the 16 existing lines optimally and exclusively. A breakdown in a train can jeopardize the proper functioning and punctuality of a line. That is why the maintenance service needs to have technological test tools to anticipate problems through predictive maintenance.

Based on periodic, systematically conducted braking performance tests, Metro de Madrid can reliably and safely roll out condition-based maintenance.

A series of measurements on three different braking systems (pneumatic brake, electrical brake, and emergency brake) lets Metro de Madrid better plan their maintenance cycles and deploy their predictive maintenance concept.

To perform brake testing on a total of 276 different metro cars, Metro de Madrid required a precise, robust, and portable system that it could install on the different trainsets. The portable and rugged Q.brixx X system proofed to be the ideal system for this application. A Q.brixx XL A108-4M1 measurement module acquires an acceleration signal from a Dytran series 7577 high precision MEMS sensor. The signal is sampled at a rate of 100 Hz, and unwanted noise is then filtered out with a fourth-order lowpass Butterworth filter. For improved robustness, the Q.brixx X system is installed inside a custom-made Pelicase.

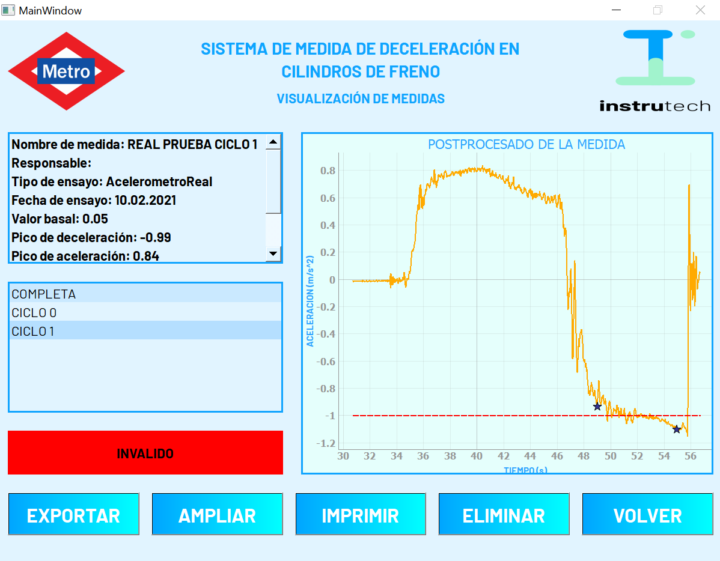

Before the braking test, the metro car is placed on a horizontal track, and the accelerometer offset is eliminated. The metro then performs an acceleration and deceleration cycle. The braking and rest endpoints are selected for each cycle. The average steady-state acceleration and deceleration values are then calculated. Next, the average acceleration value during the rest phase after the braking is calculated. This value represents the mean value. Finally, the average deceleration is calculated as the absolute value of the difference between braking deceleration and rest acceleration.

For user convenience and to ensure test repeatability, instrutechSOLUTIONS developed a custom software application. The application was written in Python, benefiting from the open and flexible interfaces known as GI.connectivity, which came free of charge with the DAQ system. The Python application allows setting the accelerator offset, displaying the measured acceleration/deceleration signal, and providing a pass/fail indication for the average deceleration measured during brake testing.

This test & measurement application showcases the versatility of Gantner’s Q.series X data acquisition system. Combining of a flexible and modular hardware platform, in combination with reliable data exchange and interoperability through various read/write interfaces, makes Gantner Instruments one of the most sought-after companies for data acquisition systems.

Modules used:

- 1x Q.brixx X station B

- 1x Q.brixx XL A108-4M1

- 1x GI.bench Data Acquisition Software

More articles

TestRig Symposium

The two-day TestRig symposium presents the current state of the art, future-oriented developments and outstanding case studies in the field of test rig construction and operation, and promotes the personal exchange of experience. The symposium will be complemented by an accompanying exhibition.

Read more...Measurement of voltage and current in high voltage systems!

With the new measurement technology from Gantner Instruments, the Q.raxx slimline A127 4CV. But what is hidden behind the new DAQ system?

Read more...The 35th Dresden Bridge Building Symposium 2026

Join us on March 18–19, 2026, in Dresden, Germany, for the 35th Dresden Bridge Construction Symposium (DBBS) - one of the most prestigious events in bridge engineering.

Read more...Trapped in Ice

Arctic ice is disappearing — the question is how fast. Summer sea ice could endure 100 more years, or it could vanish later this decade, with disastrous consequences for the rest of the planet. To nail down the answer, an expedition to the top of the world has to uncover the complex physics of ice.

Read more...