NOV (National Oilwell Vacro) is a global company in the fields of drilling and conveying technology. NOV supports the world’s most advanced drilling solutions in the oil and gas industry.

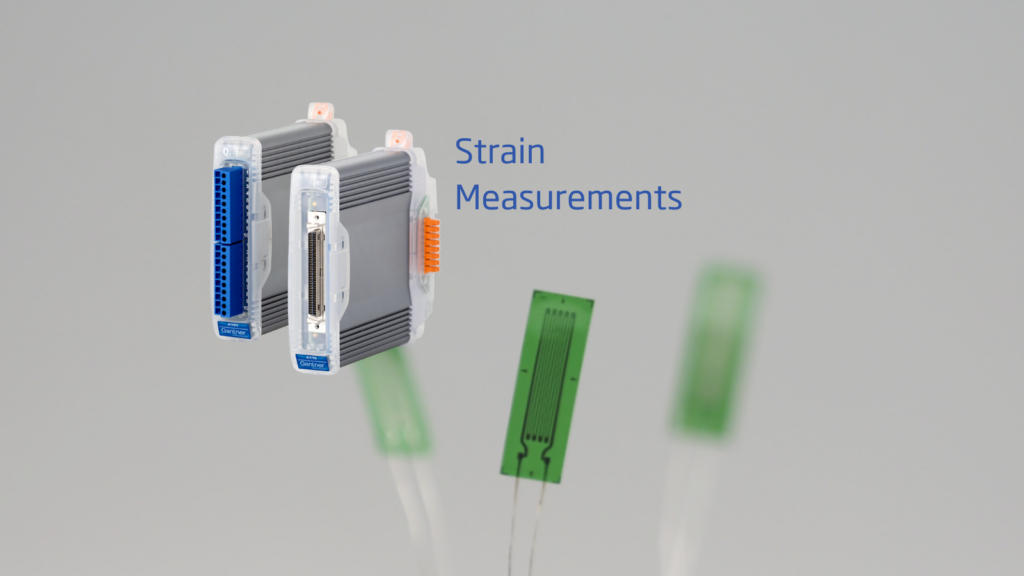

Here almost 150 measuring channels are used in a test system:

- 10 x IEPE with 5 x Q.bloxx A101

- 24 x current with 3 x Q.bloxx A108

- 12 x Pt100 with 3 x Q.bloxx A107

- 96 x SG with 12 x Q.bloxx A116

- Multiple digital I/Os

The measured data is recorded at a sample rate of 10 kHz. A data logger was configured in the Q.station test controller that records the conditioned and raw data. The recorded data is transferred to a SQL database using the test.node server software.

At present, four test systems are being built; with additional systems being planned. Testing is performed in cooperation with our Danish partner IPC Teknik ApS.

More articles

Gantner Instruments Presents Cryogenic Measurement Solutions for Hydrogen Technology

Hydrogen systems are a steadily growing field encompassing several technologies, such as liquefied hydrogen storage tanks, fuel cells, and cryogenic engines. These require meticulous temperature monitoring to ensure system integrity and performance. Operating in these low-temperature environments presents unique challenges, such as thermal contraction of materials, sensor self-heating, and the non-linearity of cryogenic sensors. Without accurate measurement, performance degradation and potential system failures become risks.

Read more...Test of Battery and Battery Management Systems

At a very early stage Gantner Instruments was involved with special products for testing of batteries in the E-Drive environment. An already existing and successful product range is now supplemented with a useful novelty.

Read more...Systèmes d’acquisition de données portables et mobiles

De nombreuses raisons justifient un système de mesure flexible et robuste qui doit être facile à transporter pour collecter des données de mesure à différents endroits. Il peut s'agir, par exemple, de mesures à court terme sur des machines ou des composants d'usine lors de la mise en service après un entretien, ou de mesures récurrentes sur des ponts ou d'autres ouvrages d'art.

Read more...Measurements at -40°C ambient temperature

We just tested our Q.bloxx XL A104 TCK in the climate chamber at -40°C ambient temperature and it does a perfect job under these extreme conditions.

Read more...