The team at Geosciences Rennes, a joint mixed research unit between the University of Rennes and the CNRS (UMR-6118), has been conducting monitoring experiments on the volcano La Grande Soufrière over the last 15 years. La Grande Soufrière is located in Guadeloupe, a French overseas region located in the southern Caribbean Sea.

In response to the volcano regaining activity since 2014, the Géosciences laboratory decided to increase their monitoring capacity on the top of the lava dome by deploying a network of sensors (e.g., Pt100 in fumaroles, 1D and 3D seismic geophones, thermocouples in the soil, pressure sensor and Pt100 in the boiling acid lake). The team’s previous positive experience with the Gantner Instruments’ e.series (e.reader, e.pac, and e.bloxx) led them to retain the Q.series to develop their new acquisition network.

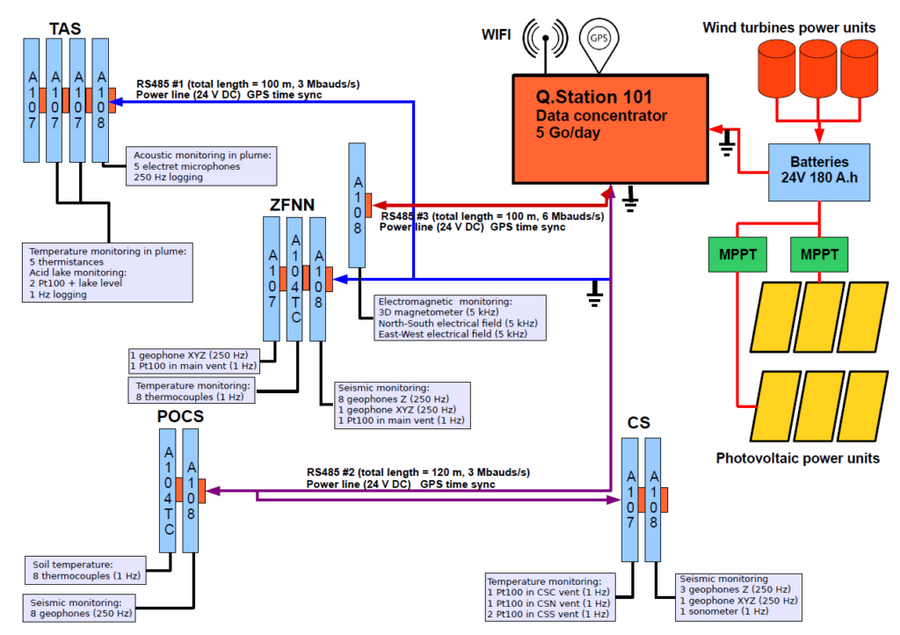

Figure 1 is a synoptic of the basic network at work since 2015: a Q.station 101 together with multiple Q.bloxx A108 and A107 modules distributed over three RS485 buses. Wind turbines and photovoltaic units provide electrical power to the network. A long-range Wi-Fi link is used to transmit the data to the volcano observatory located 10 km away. A GPS antenna is used to synchronize the Q.station, which is particularly crucial because precise time synchronization is needed to correlate the seismic data acquired with the geophones connected to A108 modules. Because of their versatility, A107 modules are used in the most active areas where multiphysics measurements are performed with either resistive, voltage, or current sensors. The A107 modules’ flexibility allows IPGP to test using their sensor prototypes in the measurement campaign.

The environmental conditions at the top of the volcano are very harsh. The main difficulties are heavy tropical rain (8,000 mm per year), strong winds, lightning storms, and acidic gases emitted by fumaroles. Despite these harsh conditions, Gantner Instruments systems remain operational almost all the time. The systems are protected using a “double box” technique. The first box on the outside is used to protect against heavy rains and wind. The conditions inside this container roughly correspond to IP62 except for the acidic gases present. A Pelican case is then placed inside the first box, which contains the DAQ system and protects against humidity and acidic gases.

The Géosciences laboratory is currently improving its acquisition network by installing several Q.stations at different locations around the volcano. This solution reduces the lengths of the RS-485 lines that appear sensitive to lightning and the GPS time synchronization provides a common time base for all measurement data.

For an example of the scientific usage of the data acquired with the Gantner Instruments DAQ platform, you may consult our recent paper regarding “Abrupt changes of hydrothermal activity in a lava dome detected by combined seismic and muon monitoring” available online.

More articles

Apprenticeship at Gantner Instruments

We open our doors to exclusive insights into our company by talking to our apprentice, Philip, about his experiences with his apprenticeship at Gantner Instruments. In this interview, Philip tells us his story, from his search for an apprenticeship to his everyday life with us, and provides a deeper insight into a corporate culture that is much more than just a workplace.

Read more...Innovation in Alpine Solar: Overcoming Winter Energy Challenges

Switzerland is investing in the untapped potential of Alpine photovoltaic (PV) generation and making strides toward a sustainable future. This blog explores the innovative Sedrun Solar project, a pioneering high-altitude PV initiative to fill the winter energy gap. Uncover how rigorous testing and insightful data collection, facilitated by Gantner Instruments, are paving the way for optimizing this renewable energy source.

Read more...IPERMON – Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity

Currently, a vast amount of research institutions and organizations are focusing on ways to improve the operation, reliability and consequently the output of PV systems. An important aspect yet to be targeted remains the procedural and standardized approach to calculate accurately the factors behind the various performance loss mechanisms, while also detecting and diagnosing potential failures at early stages or before occurrence. Identification of degradation and failure modes at preliminary stages is important as these mechanisms directly influence the performance, lifetime and reliability of PV technology.

Read more...6 Tips for Stress-free Strain Measurement during Fatigue Testing of Aircraft Structures

Strain is the single most important measurement during aircraft fatigue testing. The accuracy and precision of strain gauge measurements is of the greatest importance to exactly determine the durability and damage tolerance of a structure. The higher a structure is in the ‘pyramid of test’, the higher the test complexity, number of measurement channels, and data produced. On top of that the risk in terms of time delay and cost associated to a test program increases more than proportional with the increase in test complexity. Here are six tips to help you choose the right data acquisition system for your fatigue test:

Read more...