Combining Strengths: Gantner Instruments and i4M Technologies Announce Cooperation Agreement for Wired and Wireless Data Acquisition

By integrating wired and wireless sensor technologies, this collaboration aims to deliver versatile, high-performance measurement systems capable of meeting the diverse demands of modern testing and monitoring applications. Whether you are engaged in structural health monitoring (SHM), condition monitoring of rotating machinery, or demanding dynamic testing applications, our advanced technologies deliver precise, time-synchronized data acquisition from both wired and wireless sensors.

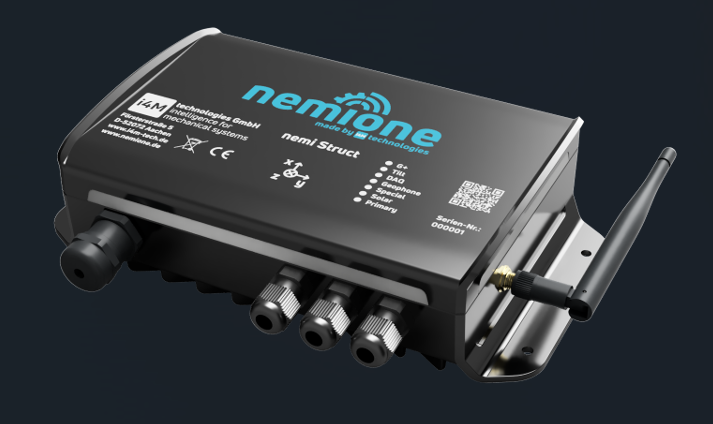

Introducing nemi Struct: The Flexible Structural Health Monitoring Solution

Gantner Instruments, in cooperation with i4M Technologies, is proud to announce the launch of nemi Struct, a versatile and robust SHM solution leveraging the proven nemione® product family. Designed to optimize efficiency, ease installation, and reduce maintenance costs, nemi Struct is ideally suited for monitoring structural integrity across buildings, bridges, and critical infrastructure.

Key Features of nemi Struct:

- Comprehensive Measurement Capabilities: nemi Struct supports a broad spectrum of measurements, including strain, temperature, crack width, tilt, vibrations, and oscillations. By selecting the ideal nemione measuring units for your requirements, nemi Struct ensures precision and reliability in data acquisition.

- Flexible Energy Options: nemi Struct offers various power configurations tailored to your runtime needs, including long-life primary cells, rechargeable batteries, or battery packs combined with solar panels. This flexibility guarantees continuous operation even in remote locations.

- Wireless Efficiency: By adopting wireless sensor technology, nemi Struct significantly reduces installation complexity and costs, making it particularly advantageous for monitoring extensive structures. The wireless design facilitates straightforward deployment, easy maintenance, and cost-effective scalability.

Thanks to its flexible design and configuration options, nemi Struct enables continuous, long-term monitoring of structural integrity, allowing early detection and proactive management of structural damage across all your SHM projects.

Explore nemi Struct in detail through this introductory video:

Wireless Sensor Solutions for Precision and Efficiency in Challenging Applications

i4M Technologies, a rising leader in wireless measurement technology, has developed advanced wireless sensor systems for precise measurement of parameters like strain, force, vibration, rotation, and temperature. Gantner Instruments is now offering these next-generation wireless sensors, characterized by:

- High Speed & Precision: Achieve up to 24-bit resolution with high sampling rates, significantly enhancing data quality and accuracy.

- High Channel Capacity: Increased measurement channels per wireless network reduce the complexity of system setup, minimizing costs.

- Low Energy Consumption: Ultra-low-power sensor designs extend battery life, decreasing maintenance intervals and operational downtime.

- Integrated Data Acquisition: Seamlessly integrate time-synchronized data collection from both wired and wireless sensors within a single data acquisition system.

Our new wireless sensors deliver substantial cost reductions by eliminating complex wiring, making them especially suitable for large-scale infrastructure monitoring and dynamic applications such as wind turbine and rotating machinery monitoring. Equipped with an integrated 9-DoF Inertial Measurement Unit (IMU), these sensors capture essential data, including acceleration, rotation rates, rotation angles, and magnetic fields across three axes, enabling advanced condition analysis in real-time.

Powerful Integration of Wireless Sensors into Gantner’s Data Ecosystem

The integration of wireless sensors into Gantner Instruments’ data acquisition ecosystem is fully supported by advanced software platforms such as GI.bench and GI.cloud. These platforms offer robust data logging, visualization, alarming, and analysis tools, along with open interfaces such as EtherCAT, Modbus, OPC UA, and MQTT for seamless system integration and interoperability.

The cooperation agreement between Gantner Instruments and i4M Technologies marks a significant leap forward in synchronized data acquisition capabilities. By combining expertise in both wired and wireless technology domains, we are set to lead the industry in providing versatile, high-performance solutions tailored to the rapidly evolving needs of test and measurement applications.

Wireless sensor solutions from i4M Technologies, including the new nemi Struct, are now available directly through Gantner Instruments. Contact your local representative today to discover how these cutting-edge wireless technologies can streamline your operations, enhance data reliability, and significantly reduce costs.

More articles

Boeing 777X folding wingtip

Boeing is looking to debut a new and ambitious aircraft in 2020: the 777X, a dual-aisle, twin-engine aircraft that is built around fuel efficiency. The aircraft is designed to use 12% less fuel than any competing aircraft and 20% less fuel than today’s 777.

Read more...Dynamic High Voltage Measurement: Q.series X A128 Plus SEB

Gantner Instruments introduces the Q.series X A128 Plus SEB, a dynamic high-voltage data acquisition solution.

Read more...A Step Closer to Near-Supersonic Train Travel

South Korea’s hyperloop train reaches over 1,000 km/h in recent tests.

Read more...Cloud-based Railway Bridge Monitoring with Solar Powered Q.series DAQ

For a large railway operator, Gantner Instruments continuously monitors a railway bridge using displacement transducers to detect deflection in bridge support elements.

Read more...