Engine &

Powertrain Testing

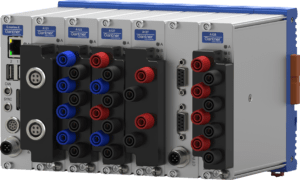

An internal combustion engine (ICE) needs continuous, long-term testing to ensure its safety and suitability. To accurately characterize engine performance at different working conditions, speed, torque, temperature, and vibration parameters must be measured with varying sample rates. Continuous testing around-the-clock is putting stringent uptime requirements on the data acquisition system. The Q.series X’s accuracy, flexibility, and reliability make it the data acquisition system of choice for the world‘s leading engine manufacturers and test facilities.

A dynamometer is a device that measures the force, torque, or power, giving a full breakdown of the engine’s performance. More specifically, a dyno test evaluates the measure of torque and rotational speed, giving a reading that indicates the amount of power in the engine.

A real-world testing method to get accurate power results; Vehicle components, such as the transmission and drive axle, both require a certain amount of power to operate, which results in parasitic power loss from the engine as measured at the flywheel during the engine dynamometer testing.

Hot testing is the best way to obtain all the information needed for checking the engine’s performance to achieve type approvals and certifications. Typical measurements include engine oil pressure and temperature, combustion air and exhaust gas temperature, engine speed, useful power, and torque.

Thermal shock tests assess the interaction between an internal combustion engine operation, a range of cooling and lubrication system thermal cycling scenarios, and the wear and thermal deformation of individual engine components.

Transmission durability tests allow the durability and performance of gearboxes at significant mileage to be tested much faster than if conducted via on-road tests. Due to their repeatability, these tests allow comparing various design solutions.

Why Gantner Instruments

01

Flexible Mixed-Signal Data Acquisition

Need Expert Results Fast?

02

Minimal Signal-to-Noise Ratio

Minimal Signal-to-Noise Ratio

03

Fully Configurable Data Loggers

Need Expert Results Fast?

04

Easy Integration

Need Expert Results Fast?

05

No Downtime

Need Expert Results Fast?

06

1500V High-Voltage Galvanic Isolation

1500V High-Voltage Galvanic Isolation

Who trusts Gantner for Combustion Engine & Powertrain Testing?

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.