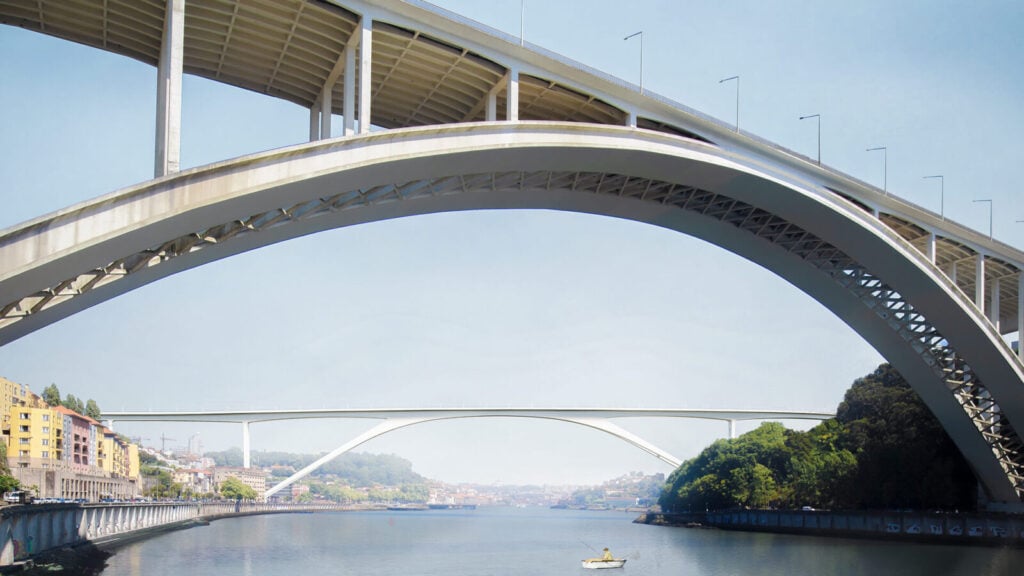

Unique construction challenges

The design of Ponte Ferreirinha presents several significant structural challenges. Its 428,60-meter main span requires supports outside the riverbed to protect the environment, which complicates load distribution and foundation design. The steep riverbanks and nearby buildings limit pier placement and demand a highly efficient frame structure with long side spans. The bridge’s slender, 75-meter-high, variable-depth prestressed reinforced concrete superstructure, supported by long inclined struts, must remain stable under wind, seismic forces, and high compression. Construction relies on balanced cantilever techniques with temporary cable stays, all while minimizing interference with the Douro River and surrounding infrastructure.

Why structural health monitoring matters

The construction of complex structures requires continuous monitoring using online systems that provide permanent oversight. In this context, a Structural Health Monitoring (SHM) system delivers several key benefits:

- Safety first: Detects abnormal deflections, vibrations, or cable tensions to protect both workers and equipment.

- Construction support: Guides the safe advancement of cantilever segments and the tensioning of temporary cable stays.

- Time and cost saving: Identifies overstressing or misalignment early, preventing delays and costly rework.

- Design validation: Confirms that the bridge behaves as predicted under various loads, wind, and seismic forces.

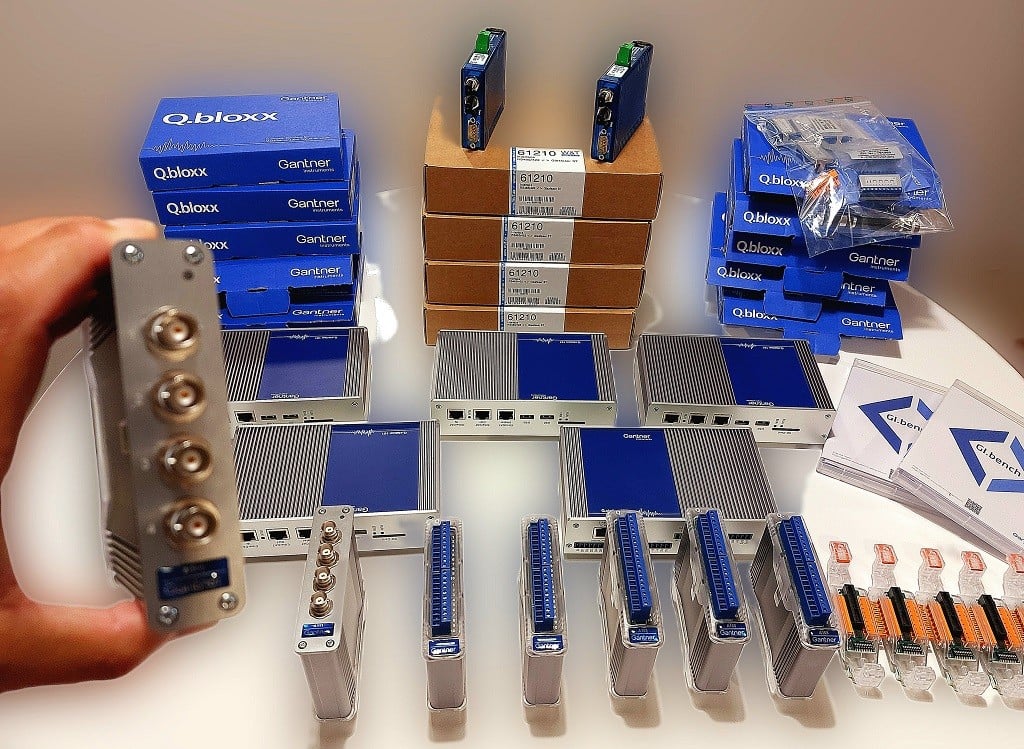

Implementing a robust DAQ system

To achieve these benefits, PerfectDecibel, Gantner Instruments’ partner in Portugal, was consulted to design a data acquisition (DAQ) system capable of meeting the project’s demanding requirements:

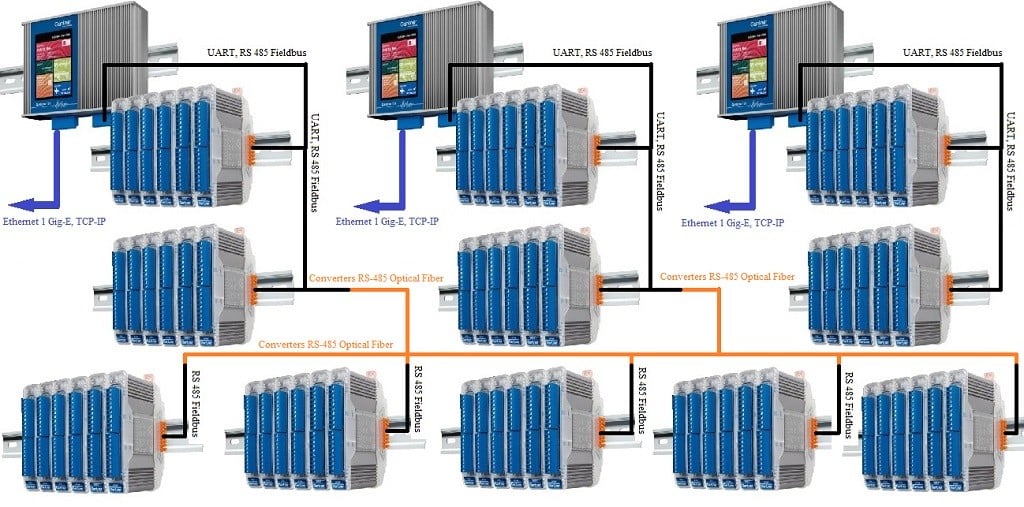

- Scalability: With construction unfolding in five phases, the DAQ system must expand seamlessly as new structural elements are completed.

- Distributed coverage: DAQ modules need to be installed close to sensors spread across several hundred meters, minimizing cable lengths and reducing noise pickup.

- Continuous operation: The system must operate autonomously 24/7, ensuring reliable monitoring under varying environmental and construction conditions.

Technical highlights

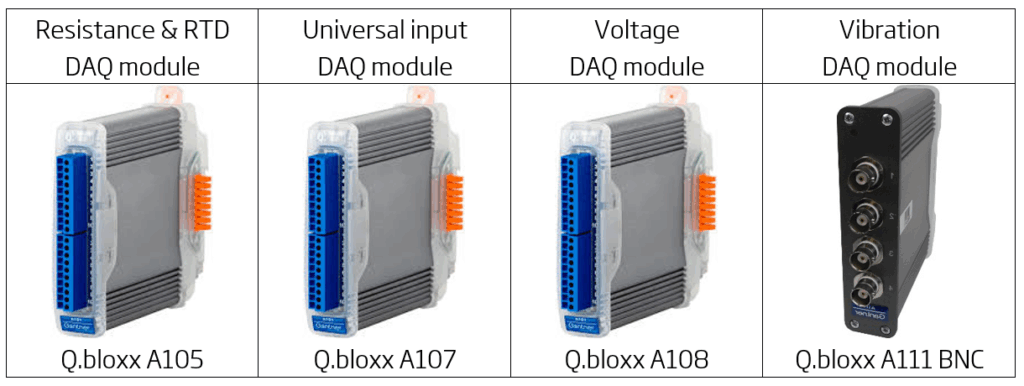

The system features a 200-channel Q.bloxx setup to monitor strain, displacement, temperature, and acceleration. It provides distributed, time-synchronized measurements from multiple sensor types using 24-bit ADCs on every channel. Each module includes pre-engineered signal conditioning, multiple filtering options, and three-way galvanic isolation to ensure stable, interference-free data.

Designed for autonomous operation, the system functions as a standalone DAQ with automatic power-on capability, operating independently of a PC while managing all critical tasks, including data processing, local storage, and buffering, to guarantee continuous, reliable monitoring throughout the construction process.

Fiber-optic communication enables distributed measurement, with sampling rates of 1 minute for strain, displacement, and temperature, and 100 Hz for vibrations. Vibrating wire sensors are integrated via Modbus, and data are stored locally and continuously sent to a remote server for real-time monitoring and analysis.

With Gantner Instruments DAQ system, engineers can make data-driven decisions, ensuring safe, efficient construction while protecting workers, equipment, and the iconic Porto skyline.

Product Spotlight

More articles

Measurements at -40°C ambient temperature

We just tested our Q.bloxx XL A104 TCK in the climate chamber at -40°C ambient temperature and it does a perfect job under these extreme conditions.

Read more...New Monitoring Solution – Q.series Portable

For short-term or rout-based condition monitoring of various assets we now provide a portable system solution. Our new Q.series Portable based on Q.station 101 and OEM-boards for analog and digital inputs contained in a robust transport case is fully engineered and ready to use ‘out of the box’. The electronic boards and the power supply system are mounted on shock absorbers to withstand heavy-duty work under harsh environments in the field.

Read more...Gantner Instruments Helps Flood Victims in the Philippines

Yet another terrible natural disaster has left its mark. In the Philippines, the typhoon Hayian has cost the lives of countless people. Gantner Instruments made a donation to support reconstruction.

Read more...Measure the evolution of battery technology

New ground-breaking products and powerful solutions for fast and accurate Cell, Module and Pack testing

Read more...