Module Configuration

Equipped with two universal analog input channels, the A101 2 x DB15HD SV ensures high-speed data capture at 100 kS/s per channel, making it well-suited for dynamic environments where rapid signal changes occur. The diversity of input ranges accommodates a broad range of sensor types and signal variations.

Input Range Flexibility

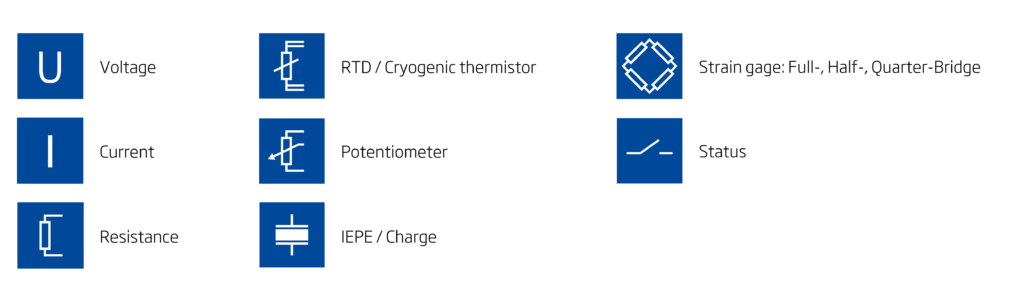

The module’s input range flexibility is designed for accommodating:

- Voltage measurements from low-level signals at ±100 mV to higher voltages up to ±10 V and 0-60 V.

- Current inputs from standard 4-20 mA loops.

- Compatibility with IEPE/ICP sensors for vibration and acoustic measurements.

- RTD support for precise temperature monitoring with Pt100 and Pt1000 sensors.

- Resistance measurements and full strain gage configurations, facilitating its use in stress and force measurements

- 3-Way galvanic isolation of 500 VDC channel-to-channel, channel-to-power supply, and -bank

Digital I/O and Connectivity

With two digital inputs or outputs, the module can handle various control and monitoring tasks such as status indication, triggering processes, taring scales, or setting alarms. The incorporation of robust 2 x DB15-HD connectors ensures dependable connections for signal integrity.

In addition to its versatile input channels and design, the Q.series X A101 2 x DB15HD SV module offers a wide range of communication and compatibility options to seamlessly integrate into various industrial systems.

- Engineers can harness its direct EtherCAT capabilities, complemented by the use of a bus coupler for EtherCAT, for efficient and high-speed data exchange.

- The module supports various interfaces such as CAN-FD, ModbusTCP, Profinet, OPC UA, and more when combined with the Q.station X, for compatibility with diverse control systems.

It also operates effectively within a temperature range of -20 °C to +60 °C, accommodating diverse industrial environments.

Sensor Supply Features

The module stands out with its programmable sensor supply for each channel, providing:

- Adjustable voltage from 3.3 V to 20 V, which can be increased to 24 V if the supply voltage is greater than 27.3 V, in fine steps of 10 mV.

- A current limit range that can be set from 50 mA to 100 mA in 100 µA increments, allowing for precise control over the power provided to each sensor.

Sensor Supply Advantages

A key feature of the Q.series X A101 module is its integrated sensor supply, which significantly simplifies the setup and enhances operational efficiency. Traditionally, active sensors like pressure transducers required separate power sources, leading to complex wiring and potential noise issues. The A101 module addresses this by providing a direct sensor supply, eliminating the need for additional power wiring.

With a programmable voltage range from 3.3 V to 20 V, extendable to 24 V, and a current limit of up to 100 mA, the A101 supports a wide array of sensors including active, amplified load cells, pressure sensors, and accelerometers. This versatility not only reduces connection points and noise but also caters to sensors with varied power requirements, ensuring reliable performance.

Power Supply Considerations

It is important to note that the module requires an additional power source for the SV bus-bar to maintain its galvanic isolation.

Operational Environment

The A101 2 x DB15HD SV is built to endure the rigors of industrial settings. Its construction allows it to function optimally in a wide temperature range from -20 °C to +60 °C, and it is resistant to humidity levels from 5 % to 95 % at 50 °C.

The Q.series X A101 2 x DB15HD SV measurement module, with its comprehensive measurement capabilities and robust design, is a compelling choice for engineers looking for a high-performance data acquisition solution. The technical merits of the module speak for themselves, offering a level of precision and versatility that aligns with the exacting standards of industrial data collection and analysis.

For a deeper understanding of the Q.series X A101 2 x DB15HD SV measurement module, check out the datasheet by clicking here. It’s a valuable resource to explore its specifications and applications.

More articles

Q.series demo at European Rotorcraft Forum

From September 5 – 8, Gantner participated in the 42nd edition of the European Rotorcraft Forum. The event was held in Lille, France.

Read more...25th International Colloquium Tribology 2026

The 25th International Colloquium Tribology takes place January 27–29, 2026, at TAE Esslingen, Germany. This special anniversary edition is held under the theme “Bridging Science and Industry – Driving a Sustainable Future with Tribology” and brings together international experts from research and industry for three days of knowledge exchange and networking.

Read more...Easy integration of Gantner Instruments product platforms into NI LabVIEW

NI LabVIEW has become an essential graphical programming environment widely used in engineering, R&D, testing, and industrial automation. Its flexibility allows engineers to quickly integrate and control diverse measurement hardware, streamlining the entire data acquisition process.

Read more...Introducing the Q.series X A12x 1500V Plus Versions

Gantner Instruments expanded the A12x module lineup with Plus versions (e.g., Q.series X A128 Plus SEB) that feature an increase in their voltage capacity up to 1500V, meeting the evolving demands of industries that require higher voltage limits for testing and measurement. Let's delve deeper into the enhanced capabilities of the A12x module lineup and how they empower engineers across various industries.

Read more...