Q.series X DAQ Modules for EtherCAT

What is Q.series XE?

All Q.series X DAQ systems possess the same measurement capabilities and performance. The main differentiating factor between the XL and XE versions of Q.series X is the Fieldbus communication protocol, which can be interchanged on Q.series X modules using a simple firmware update.

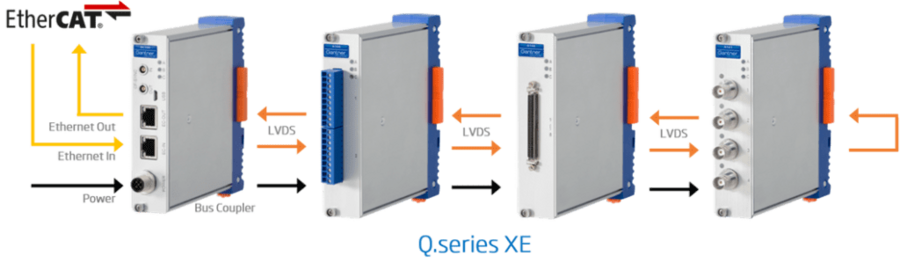

Q.series XE DAQ systems are specialized for EtherCAT (XE) Fieldbus communication. Q.series XE can also incorporate standard Q.station capabilities such as CAN, Modbus TCP/IP, Modbus RTU, PROFIBUS, PROFINET, publish/subscribe, and messaging protocols, e.g., OPC UA, DDS, MQTT, and controller plugins for customer-specific communication protocols.

Dive deeper into EtherCAT

Real-Time Ethernet

- Full-range of Q.series X I/O modules available as XE versions

- Available in Q.bloxx, Q.brixx, and Q.raxx form factors

- Pre-engineered onboard signal condition

- ET1100 EtherCAT slave controller that is fully compliant with the

- EtherCAT slave implementation standard ETG.2200

- Distributed Clock for precise data synchronization

- oversampling technology for data rates up to 100 kS/s

- One bus coupler connects up to 10 I/O modules to the network

- Drop-in replacement for Beckhoff industrial I/O

Q.series XE Measuring Modules

All Q.series XE modules are flexible real-time measuring systems that can be configured.

- Read / Write Configuration via SDO

- CoE per “Modular Device Profile” (ETG.5001.1)

- File transfer via FoE (ETG.1000.5)

- Configurable PDO mapping for optimized data throughput

- Distributed clock for data synchronization (ETG.1020.0)

- Oversampling technology (oscilloscope function)

Configuration via read/write of SDO or file transfer (FoE)

Select from predefined templates:

- Template ±10 V

- Template 4…20 mA

- Template Pt100 2-wire

- Template Pt100 4-wire

- Template full bridge

- Template half-bridge

- TCK template

- TCJ template

and more…

What can Q.series XE modules measure?

Q.series X I/O Signal inputs Design – ANALOG

-

Voltage

-

Current

-

Resistance

-

Potentiometer

-

RTD / Cryogenic thermistor

-

Thermocouple

-

Strain gage: Full-, Half-, Quarter-Bridge

-

Inductive full-& half bridge

-

LVDT

-

IEPE / Charge

-

Analog output

Q.series X I/O Signal inputs Design – DIGITAL

-

Frequency / Counter

-

Pulse-width modulation

-

Time

-

Status

Q.series X I/O Signal inputs Design – HIGH VOLTAGE

-

Voltage

-

Current

-

Resistance

-

RTD

-

Thermocouple

-

Strain gage

-

IEPE

Flexible Form Factors

We offer a variety of modular packaging styles. Choose between Distributed and Flexible DIN rail modules (bloxx), Portable and Compact (brixx), or Multi-channel 19” Rack Systems (1U & 3U).

Q.series X measurement module I/O cards and front plates with their connector terminals can be interchanged between the bloxx, brixx, and raxx (3U) form factors, so you can always adapt your system’s housing with minimal investment.

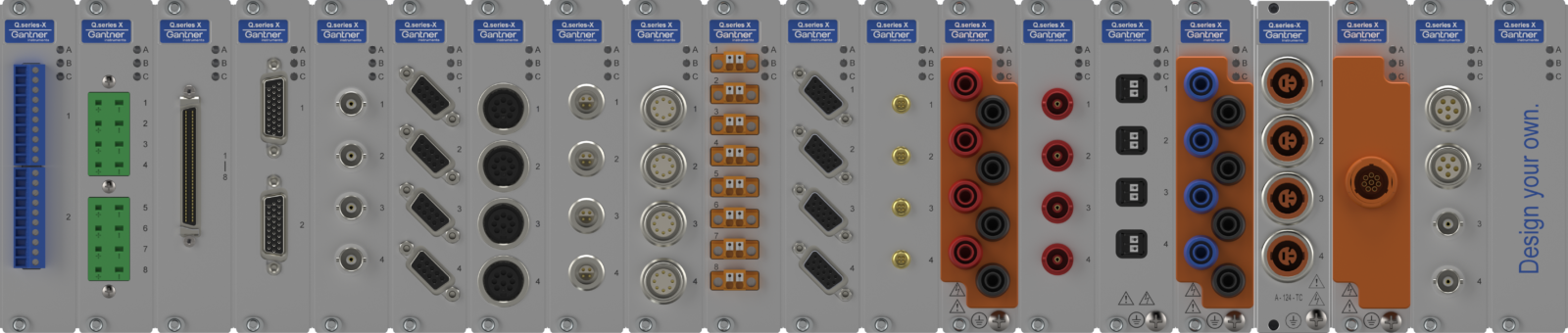

Choose Your Connectors

Whitepaper EtherCAT

Dive deeper into EtherCAT with our knowledge base.

Applications

The versatility of Gantner DAQ products makes them ideal for:

GI Productfinder

Find the right products for your application in a matter of seconds.

FAQ

These are frequently asked questions regarding our EtherCAT:

EtherCAT (Ethernet for Control Automation Technology) is a high-speed, real-time industrial network protocol designed for automation and data acquisition systems. Beckhoff Automation originally developed it and is now standardized under IEC 61158. Unlike regular Ethernet communication, EtherCAT is built for determinism and low latency: an EtherCAT master sends out a frame that each slave device (sensor, actuator, I/O module, etc.) processes on the fly. As the frame passes through, slaves write their data to and read data from it, then the frame returns to the master – all in one continuous stream. This makes EtherCAT extremely fast and efficient for connecting dozens of devices with minimal delay. In practical terms, a data acquisition system using EtherCAT can gather synchronized measurements from many modules (voltage, thermocouple, strain, etc.) with cycle times in the order of 100 μs to a few milliseconds, which is much faster than traditional fieldbuses.

An EtherCAT network is typically a daisy-chained or ring topology (it can be line, star, or tree as well). Each EtherCAT slave is assigned an address, but the EtherCAT frame is not stopped and started at each device – it’s processed as a continuous telegram that hardware in the slave devices handles in real-time. This protocol brings the “power and flexibility of Ethernet” to industrial control, but ensures the timing determinism needed for control loops and synchronized acquisition. For example, you might have an EtherCAT master in a PC or PLC, and multiple EtherCAT-capable measurement modules daisy-chained. The master sends a request frame, and within a few microseconds, each module has inserted its current sensor readings into the frame and passed it along. When the frame comes back, the master has all measurements virtually simultaneously. In summary, EtherCAT is a real-time Ethernet fieldbus for industrial automation, known for its high speed, low jitter, and ability to connect a large number of I/O devices easily.