IPERMON

“Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity”

About IPERMON

Scope

A key factor that will enable the further increase of the uptake of the technology is the reduction of PV electricity costs by increasing the lifetime output as highlighted by the Solar Europe Industry Initiative (SEII). This can be achieved by improving the reliability and service lifetime performance through constant, solid and traceable PV plant monitoring of installed systems, hence directly impacting positively investment cost, levelised cost of electricity (LCoE) and in general PV competitiveness. In this sense, a main challenge in the quest for ensuring quality of operation especially for grid-connected PV systems is to safeguard reliability and good performance by identifying and quantifying accurately the factors behind the various performance loss mechanisms, while also detecting and diagnosing potential failures at early stages or before occurrence, through robust performance monitoring, fault detection and preventive maintenance.

Research

A leading industrial company, Gantner Instruments (GI), partnering with a research organisation, University of Cyprus (UCY), initiated a team to develop a PV performance monitoring system equipped with various advanced monitoring algorithms for detecting and diagnosing potential failures, performance losses and degradation mechanisms in photovoltaic systems at an early stage.

Goal

The ultimate goal of the project is to develop an innovative performance monitoring system that will significantly improve and ensure quality of operation of grid-connected PV systems in order to fulfil and guarantee owner/investor expectations.

Objectives

The main objective is to develop an innovative performance monitoring system that will significantly improve and ensure quality of operation of grid-connected PV systems in order to fulfil and guarantee owner/investor expectations. The system which will provide the first independent complete baseline solution to ensure operational quality and optimise energy production will comprise of a complete structural sensor and data acquisition platform with high sampling capabilities, large storage databases and an advanced web-portal to incorporate the research originating performance loss, failure routines and degradation quantification algorithms for real-time analysis. In this sense, the algorithms and tools will provide the baseline to ensure PV plant performance quality assurance, energy yield optimisation, reflect financial parameters and provide accurate day-ahead production forecasts.

The aims of the proposed project will be to:

- Assess performance losses, failures and degradation mechanisms.

- Formulate a procedural protocol and guidelines for the identification and quantification of losses, failures and degradation of PV systems.

- Develop capacity rating, performance loss and degradation algorithms that will be incorporated as software modules to the advanced monitoring system.

- Optimise energy yield prediction for accurate production forecasts and

- Demonstrate O&M support including triggers and preventive maintenance.

The project can enable large scale deployment of PV, increase the competitiveness of the technology (both technical and economical) and safeguard the investment.

The Main Project Activities

- Formulation of guidelines for the installation of sensors and data-acquisition device.

- Development of algorithms for the identification of performance losses.

- Development of routines to detect failures that occur at the module, array and system level.

- Benchmarking of algorithms for the identification of performance losses and failures on a number of grid-connected PV systems currently available at UCY (1 minute data-set analysis).

- Formulation of algorithms for the identification and quantification of long term degradation. Algorithms will be also tested at the GI Outdoor Test Facility (OTF) in Arizona.

- Formulation and verification of PV production prediction algorithms for day ahead forecast. The forecasts will be verified against real outdoor measurements.

- Development of performance monitoring system prototype and operational verification with real power plant data from GI’s network.

- Development of pre-commercial product and integration on GI’s existing monitoring platform.

Work Packages

The activities of the research project are divided in six work-packages (WPs).

The Architecture of GI.bench

Project Management (WP1)

Formulation and benchmarking (WP2)

Capacity testing (WP3)

Development (WP4)

Integration and testing (WP5)

Dissemination of results (WP6)

Project Management (WP1)

Formulation and benchmarking (WP2)

Capacity testing (WP3)

Development (WP4)

Integration and testing (WP5)

Dissemination of results (WP6)

The latests Results Emerging From the Work Packages

Result 1:

Innovative data quality routines (data verification and correction) to ensure high levels of data sanity which is an essential part for the application of data analytics.

Result 2:

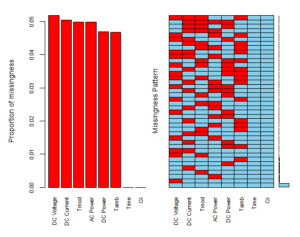

Routines to detect erroneous data and sensor drifts for reactive and proactive maintenance (data missingness matrix).

Result 3:

Capacity test employing different methods (ASTM Regression Method, IEC 61724 method and the mechanistic performance model) to present accurately the power performance index (PPI) and initiate alerts when set thresholds are exceeded.

Result 4:

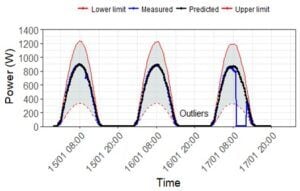

Detailed verification and bench marking of failure detection and classification events at test-bench systems at the University of Cyprus and actual power plants administered by GI

Result 5:

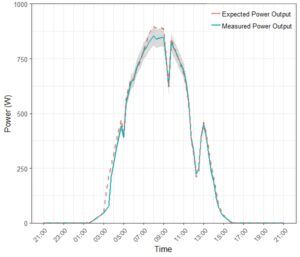

Health-state detector to quantify the performance on a daily basis of PV power plants against a digital twin accurate performance replica (mechanistic performance model). The monitor can detect and classify commonly exhibited failures with over 98 % accuracy.

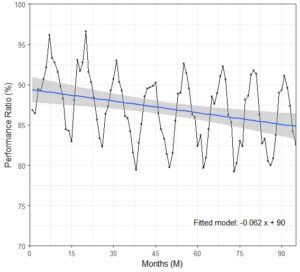

Result 6:

Accurate calculation of long-term degradation rate by utilizing all commonly applied time series analytical and statistical techniques (OLS, ARIMA, CSD and YoY).

Result 7:

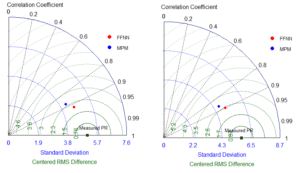

Benchmarking the predictive accuracy of machine learning and the mechanistic performance model. Taylor diagram shows that both models can predict accurately the performance of PV systems (accuracy error <2 %).