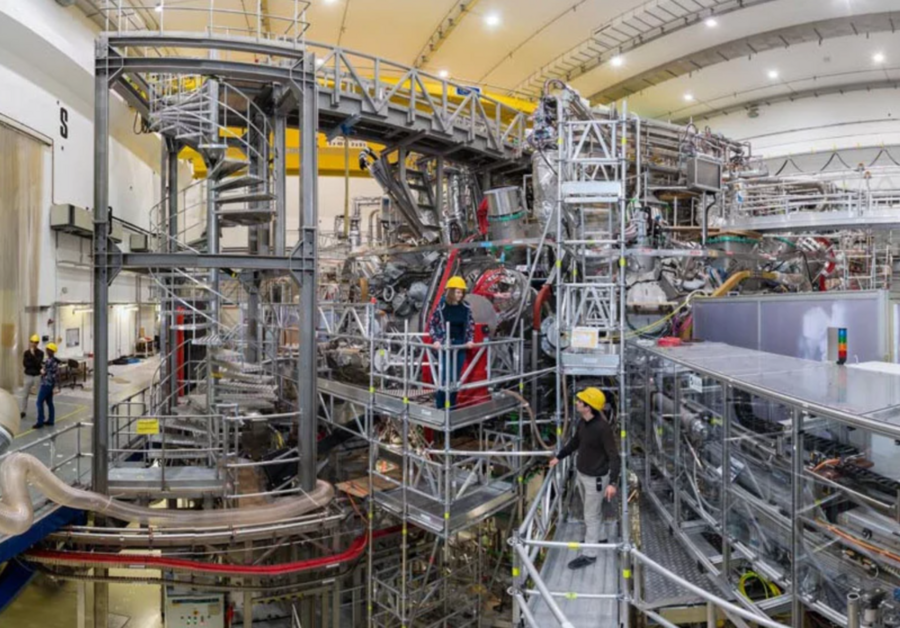

The Max Planck Institute for Plasma Physics (IPP) is engaged in research into the fundamentals of a power plant that – like the sun – will generate energy from the fusion of light atomic nuclei.

1. A5-1CR e.bloxx Measuring Module for Logging Low Temperatures

Special Cernox and TVOl cryogenic sensors were used to measure low temperatures beginning at 3 Kelvin. These sensors have special characteristics with a resistance of approx. 3,000 to 8,000 Ohms at 3 Kelvin dropping to approx. 30 to 100 Ohms at room temperature.

2. A101IPP Measuring Module

Special low temperature strain gages with half bridges were used for measuring the strain on the coil bodies. The knowledge gained from the series of tests resulted in continuously new requirements being placed on the measuring amplifiers during the course of this cooperative project.

Since the strain gages were located in a strong magnetic field with values up to 6 Tesla, carrier frequency technology was used initially. Here, however, the microphonics effect resulted in vibration in the measuring lines (alternating current in magnetic field). Moreover it was also necessary here to minimize the power consumption on the half bridges. The solution was a pulsed bridge excitation voltage with special filters to guarantee soft on and off switching and thus a low dU/dt ratio.

The test series was nearly completed when it became apparent that the special alloys at the power feedthroughs into the plasma chamber resulted in thermoelectric voltages at the contact points, which reached nearly the level of the strain gage signal voltages themselves. The objective was then to compensate these thermoelectric voltages to ensure pure stress measurement. The measuring cycle already established was supplemented to include additional measurement of the thermoelectric voltage during the strain gage measuring pauses when the excitation voltage was switched off.

3. A107IPP Measuring Module

Modified A107IPP Q.bloxx modules are used at approx. 1,000 other Pt 100 measuring points.

The space required is also an important factor for a number of the 2,000 measuring points. With a width of 25 mm, the A101IPP Q.bloxx top hat rail module offers two and the A107IPP Q.bloxx module four measuring channels.

The modules are connected in groups to a number of Q.gate test controllers over a high speed serial RS485 interface. Here all data is logged synchronously, provided with a time signal and sent on to a server over a common instrument network.

The measuring systems are presently being installed; this trend-setting fusion reactor is scheduled to be put into test operation in 2014.

Use of nuclear fusion as a new, environmentally friendly source of energy could prove to be a turning point in the discussion regarding increasing energy requirements in emerging economies, the finite nature of fossil fuels as energy sources and the problems involved with CO2 emissions.

Come along for a virtual tour!

Click on the picture below for a spectacular 360-degree panorama tour!

More articles

Mercedes GLC 350e plug-in hybrid – Photo Session in Schruns

Daimler used our company building in Schruns as the backdrop for the photo shoot for this year’s world premiere of the Mercedes-Benz GLC 350e plug-in hybrid.

Read more...Dynamic High Voltage Measurement: Q.series X A128 Plus SEB

Gantner Instruments introduces the Q.series X A128 Plus SEB, a dynamic high-voltage data acquisition solution.

Read more...Introducing the Q.series X A12x 1500V Plus Versions

Gantner Instruments expanded the A12x module lineup with Plus versions (e.g., Q.series X A128 Plus SEB) that feature an increase in their voltage capacity up to 1500V, meeting the evolving demands of industries that require higher voltage limits for testing and measurement. Let's delve deeper into the enhanced capabilities of the A12x module lineup and how they empower engineers across various industries.

Read more...Symposium on International Automotive Technology

The Symposium on International Automotive Technology (SIAT 2026) returns to Pune from January 28–30, bringing together engineers, researchers, and technical leaders shaping the future of safe, sustainable mobility.

Read more...