Looking inside a drinking water reactor

In the Netherlands, more than 400 million m³ (100 billion gallons) of water is softened in drinking water treatment plants annually. Softening is a complicated physical and chemical process in fluidized bed reactors. In a fluidized bed, particles of approximately 1 mm are elevated using an upward water stream, creating a large surface area. Maintaining optimal process conditions requires real-time information about the fluidized bed condition. Until recently, it was impossible to fully grasp fluidized bed dynamics from the outside of the reactor. Waternet, the water supply company for Amsterdam and surrounding areas, aimed to develop an innovative soft sensor (1) – the Hydrometer – that can continuously monitor the state of the fluidized bed inside the reactor. This research was a collaborative initiative with University of Applied Sciences Utrecht, Queen Mary University of London, TU Delft, Bienfait, and Gantner Instruments.

Optimizing the water softening process

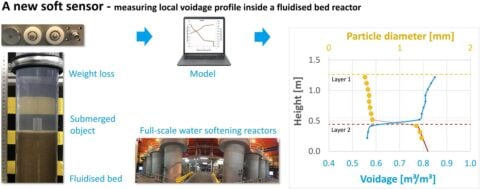

The softening process occurs in fluidized bed reactors, partially filled with seed material such as sand, garnet, and calcite pellets. Water is pumped upward, maintaining the pellet bed in a fluidized state. Caustic soda is added as a reagent for calcium carbonate crystallization on the surface of calcite pellets. Crystallization causes the pellets to grow and sink towards to bottom of the reactor. Larger pellets reduce the available surface area, adversely affecting the crystallization efficiency. Maintaining optimal process conditions requires real-time information about the fluidized state of the pellet bed to determine the amount of caustic soda required for an optimal crystallization process. This real-time information also prevents overdoses of caustic soda, preventing adverse impacts on water quality, process sustainability, and cost. The Hydrometer soft sensor aims to obtain longitudinal information in a fluidized bed reactor and subsequently determine the longitudinal voidage (2) and particle diameter profile using an empirical model.

Hydrometer proof of concept

The Hydrometer soft sensor is based on the underwater weighing method, also known as Archimedes’ principle. Archimedes found that the upward buoyant force on a submerged body was equal to the mass of the displaced liquid. The displaced volume is equal to the volume of the body submerged in the liquid. The Hydrometer is designed to let a submerged floating object hang at different heights in a fluidized calcite pellet bed and measure the buoyancy force at those positions.

To demonstrate the feasibility of the Hydrometer, Waternet and the University of Applied Sciences Utrecht designed an experimental test setup using a transparent cylinder filled with glass beads and calcite pellets to simulate the softening reactor. A smart pulley sensor designed by Bienfait is mounted above the cylinder to move a floating object controlled by a stepper motor vertically through the fluidized bed. A pulley load cell (P100/3W, Gicam) and an incremental rotary encoder (Rotapulse I28, Lika Electronics) measure the weight and position of the floating object inside the cylinder. The stepper motor, encoder, and load cell are connected to a Q.series data acquisition and control system consisting of a Q.monixx controller and Q.bloxx D101 digital input module.

The smart pulley sensor comprises four components to move the object up and down the cylinder and measure its weight and position. The floating object is attached to a thin, braided fishing line. The line is strung over the first pulley equipped with the rotary encoder that transmits the number of steps from a set zero point to the Q.bloxx D101 measurement module. The braided line passes under the second pulley equipped with a load cell that measures the strain in voltage. This measured strain has a linear correlation with the mass of the floating object. The braided line is threaded over the third pulley for support. It connects to the stepper motor, which moves the floating object up and down in the cylinder.

The test system configuration and data recording are performed using the GI.bench data acquisition software. The Q.monixx continuously streams data to the GI.bench software running on a PC. Using the sensor scaling feature in GI.bench, the measured data from the encoder and load cell are converted from the number of steps [#] to position [m] and strain [V] to mass [kg]. Online dashboards allow the operators to monitor the test in real-time and user-configurable data loggers write the measurement data to file at the optimal sample rate.

The engineers from Waternet developed a test.con routine to automate the test and ensure repeatable and comparable test results. The routine moves the floating object in pre-defined steps to different heights in the cylinder for measurement. test.con is Gantner’s free visual programming language for engineers to create custom applications for test automation and analysis. For the Hydrometer experimental setup, Waternet achieved 20 measurements per test run within approximately 30 min.

Knowledge acquired

The newly developed Hydrometer soft sensor has proven to be a more time-effective method for obtaining the hydraulic state in full-scale fluidized bed reactors. The benefits of a longitudinal sensor for daily process control are real-time access to the particle bed behavior and greater flexibility with changing water flow and process conditions.

Following the Hydrometer’s proof of concept testing, voidage could be estimated with an error of 5 % and the particle size with approximately 10 % in combination with a data-driven model. To further improve the accuracy and reliability of the Hydrometer several aspects need further development. Such as optimizing the measurement accuracy in the lower regions of the fluidized bed, adding differential pressure sensors to improve model validation, and applying CFD (computational fluid dynamics) to better model the particle-fluid-object interactions.

Programming a test.con routine in the Q.monixx has benefited the test results significantly.

Waternet

Besides the number of data points, the optimal interval between measurements could also be determined, improving the time efficiency of the tests. It may significantly improve water treatment processes such as more flexible operations, better water quality, fewer risks for approaching undesirable fluidization states, and less chemical usage.

Are you interested to learn more about test automation and the many other features that test.con has to offer?

More information

O.J.I. Kramer, C. van Schaik, J.J. Hangelbroek, P.J. de Moel, M.G. Colin, M. Amsing, E.S. Boek, W.P. Breugem, J.T. Padding, J.P. van der Hoek, A novel sensor measuring local voidage profile inside a fluidised bed reactor, Journal of Water Process Engineering 41C (2021), pp. 1-15, https://doi.org/10.1016/j.jwpe.2021.102091

Watch the video below to see the development of the Hydrometer sensor in action.

Footnote:

(1) A soft sensor is a virtual model that converts various inputs from simple sensors and combines them to mimic the output of a more complex sensor.

(2) Voidage is the fraction of the fluidized bed’s total volume, which is free space available for the flow of fluids.

More articles

GI.service Asset performance optimizer

With the significant investments being made in distributed renewable energies, the global energy market is changing from a central supply concept to a decentralized system. This transition is presenting companies in the energy market with various strategic and technical challenges to achieve efficient operations.

Read more...SEDS Colossus Static Fire System Test Stand Unveiling

The SEDS-Students for the Exploration and Development of Space-organization at the University of California San Diego, recently held a launch gathering to unveil the final design and build of their Colossus static fire system test stand.

Read more...The Battery Show Europe 2025

Curious about Gantner Instruments' latest innovations? Dive into our battery testing blog and discover what we have in store for The Battery Show Europe 2025!

Read more...Seconds Matter: Real-Time Decisions for Smarter Energy Systems

The future of energy isn’t just about generating more power—it’s about using it smarter, faster, and more efficiently. The challenge? Energy systems are more complex than ever. Renewable integration, grid decentralization, and industrial energy demands are pushing operators to make split-second decisions that directly impact efficiency, stability, and cost.

Read more...