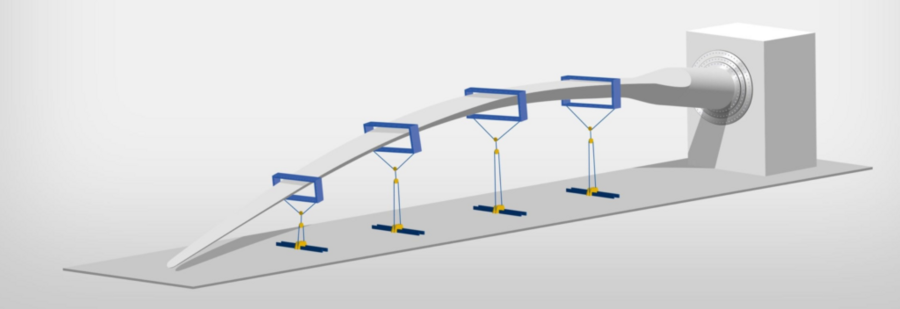

As the size of wind turbines whose blades will soon exceed the 100 m mark and generate power of up to 8 MW, the question of the material (composites) and its strength is an ongoing issue. The Danish Test Center BLAEST in Aalborg has specialized in the testing of components of wind turbines.

The test center BLAEST, owned by the leading wind technology institutes Force Technology, Technical University of Denmark (DTU – Risø) and Det Norske Veritas DNV Germanischer Lloyd – GL operates several test stands for strength and fatigue testing of rotor blades.

The prototype of each rotor blade has to be tested before approval, and series production on its strength. These tests are carried out in accordance with IEC 61400-23. BLAEST is certified for the complete test.

Read on this topic, our cover story in the issue 03/2016 of the journal mpa here!

More articles

Staying Ahead of the Curve: Meeting the Challenges of EV Powertrain Testing

In this blog post we show in advance the technical challenges of testing electric vehicles and measuring power quality and how the innovative solutions from Gantner Instruments can help to overcome these challenges.

Read more...SUPSI PVLab Industry Days

On November 29 & 30, 2021, a webinar organized by SUPSI will be held on the topic of “Quality of production and production of energy”.

Read more...Overcoming Challenges in Building Safe and Efficient Test Benches with test.con

Addressing Critical Obstacles in Test Bench Development

Developing test benches that comply with stringent safety standards and regulatory requirements is unavoidable in industries like automotive, energy, and medical technology. However, this process presents unique challenges, including navigating complex compliance landscapes, integrating diverse systems, managing operational risks, and ensuring thorough documentation. Below, we examine these challenges and demonstrate how Gantner Instruments' test.con software can effectively address them.

Gantner Instruments and PhotonFirst Sign MoU

Gantner Instruments and PhotonFirst have signed an MoU to advance fiber optic sensing technologies. This partnership focuses on innovative measurement solutions.

Read more...