Rob Stockham, Managing Director of GI Systems Ltd, Gantner’s principal United Kingdom sales representative, is really encouraged with the possibilities for growth and development in business opportunities for both companies. Having known and worked with Sella Controls in various forms for more than 30 years, they exemplify engineering competence and integrity in the design and delivery of monitoring, control, and safety systems to the most demanding industries.

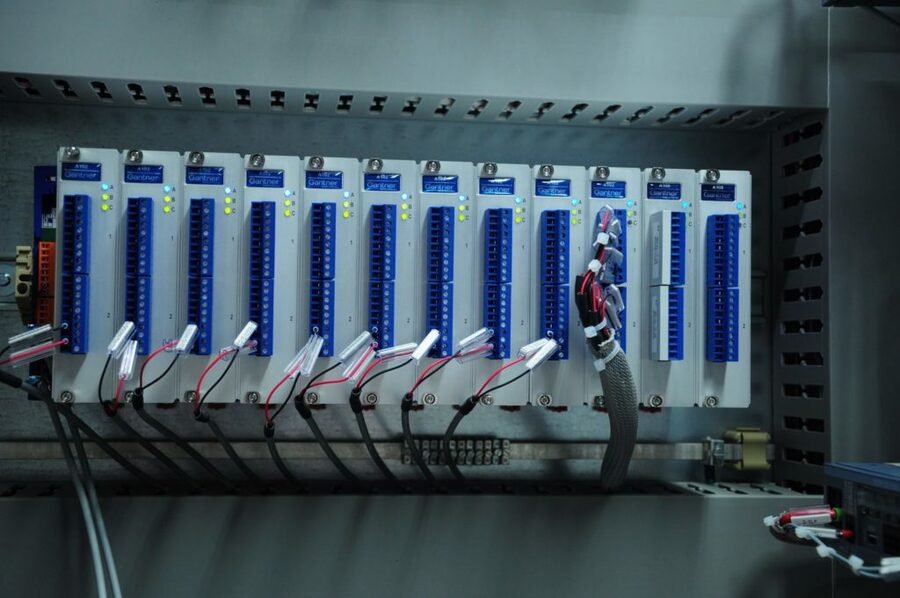

Both companies have already successfully completed several projects, where Gantner Instruments’ expertise and product offerings met the demanding requirements for vibration, thermal and process measurements. This was combined with our integrated data platform, including bulk data pre- and postprocessing, real time visualisation and analytics.

Now we look forward to offering more test, measurement and condition monitoring solutions for customers in Sella Controls’ key industrial sectors of Process, Oil & Gas, Energy, Steel, and Rail.

More articles

GI.bench is OUT!

We continue to improve our GI.bench data acquisition software with a strong focus on making it a scalable platform that is easy to use for both small high-speed measurement and high-channel-count, mixed-signal data acquisition applications.

Read more...How to keep up when measuring the Evolution of battery technology

As a professional in battery development, it is essential to perform cycling and stress testing before installing batteries in electric vehicles (EVs) or other products. Testing and monitoring help ensure functionality, reliability, safety, quality, cost, efficiency, and power quality.

Read more...PV & Grid Integration Symposium

Meet us at the 2019 PV Systems Symposium, the leading industry get together for PV Monitoring and grid integration in Albuquerque (New Mexico), United States.

Read more...GDevCon 4 Glasgow

Immerse yourself in the vibrant world of graphical programming at GDevCon 2023 on the 20th and 21st of September, from 9:00 am - 6:00 pm, at the esteemed Glasgow Science Centre, Scotland. This conference is a must-attend event for anyone striving to push the boundaries in the fields of engineering and technology.

Read more...