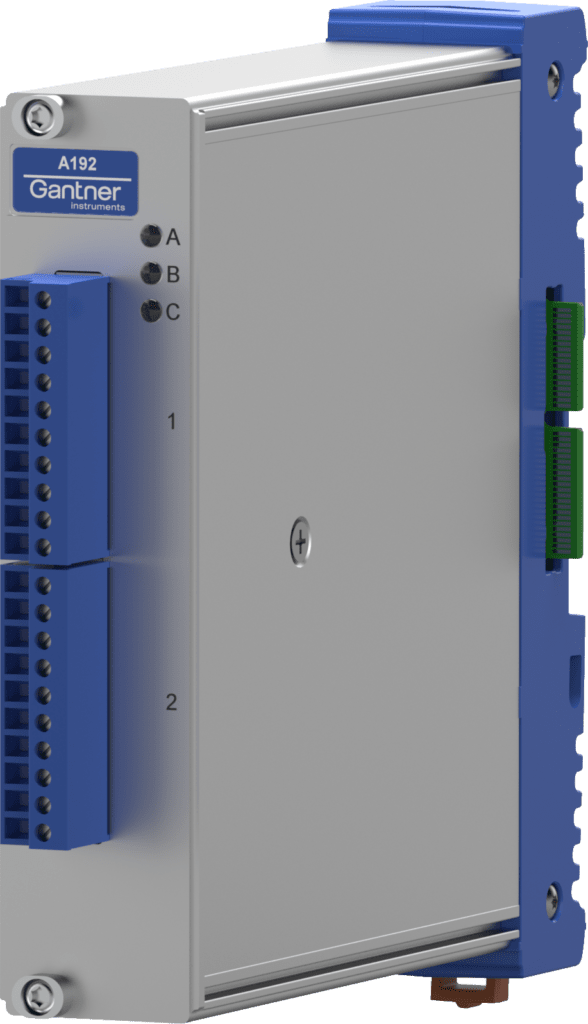

The Q.series X A192 is the newest, most flexible, and capable I/O module in the Q.series X product line. The A192 has been designed with critical (aero)space testing applications in mind, for instance static fire test of rocket engines, structural health monitoring, fatigue validation, and iron bird testing. The module’s universal analog input can be configured for either voltage, current, resistance, RTD, thermocouple, strain gage or IEPE measurement. To allow for greatest flexibility in selecting the appropriate sensors for your test bench, the A192 provides fully programmable transducer excitation in combination with an adjustable input range and amplifier gain (automatic).

Like any of the Q.series X modules, various communication busses are supported; Ethernet, EtherCAT and LocalBus. In addition, the A192 includes an analog output to share the measurement signal with, for example, a control command system or redundant data logger. The two onboard digital I/O channels are freely configurable and can be used to communicate status to the test bench emergency system. TEDS can be added to simplify system setup, self-check or for sensor traceability. And not least of all, the module comes with three-way galvanic isolation up to 500 VDC. All this makes the A192 the most versatile measurement module available for your mission-critical ground test applications.

Key Features:

- Multipurpose I/O module with 1-Ch at 100 kS/s with programmable Sensor Excitation and Analog Output

- Voltage ranges ±10 V, ±5 V, ±1 V, ±100 mV, ±10 mV

- Current range ±25 mA

- IEPE/ICP with programmable sensor excitation (1 mA to 12 mA in steps of 10 µA)

- Thermocouple

- Pt100/Pt100

- Resistance

- Strain Gage (quarter, half, full) with programmable sensor excitation (1 V to 12 V in steps of 1 mV, continuous short circuit proof)

- 1 Analog output channel

±10 VDC or ±22 mA - 2 Digital Inputs or Outputs

- Status, trigger, tare, alarm

- Standard 10-pole or customized input sockets

Find out more about our products here:

More articles

Apprenticeship at Gantner Instruments

We open our doors to exclusive insights into our company by talking to our apprentice, Philip, about his experiences with his apprenticeship at Gantner Instruments. In this interview, Philip tells us his story, from his search for an apprenticeship to his everyday life with us, and provides a deeper insight into a corporate culture that is much more than just a workplace.

Read more...Q.series X D107 SV: Digital Measurement Module with Sensor Supply

The Q.series X D107 2 x Lemo 2B SV module from Gantner Instruments provides a comprehensive solution for digital signal acquisition and sensor supply needs. Designed for distributed installations requiring precise digital measurements, this module enhances the Q.series product family's robust offering.

Read more...Historic Ship, Modern Protection: Real-Time Force Monitoring Stabilizes Sweden’s Vasa Warship

The Vasa Museum in Stockholm houses Vasa, a 17th-century Swedish warship raised from the seabed in 1961. Almost completely preserved, she is both a cultural icon and a full-scale research platform for naval architecture, materials science, and maritime archaeology. But preserving a 400-year-old oak hull on land poses a critical structural challenge: without buoyancy, the ship’s weight is carried through discrete support points, and slow deformation has already been detected. To protect Vasa for future generations, the museum is replacing the original display cradle with an adjustable steel support system equipped with a real-time force monitoring and long-term structural health monitoring (SHM) solution.

Read more...GI.bench is OUT!

We continue to improve our GI.bench data acquisition software with a strong focus on making it a scalable platform that is easy to use for both small high-speed measurement and high-channel-count, mixed-signal data acquisition applications.

Read more...