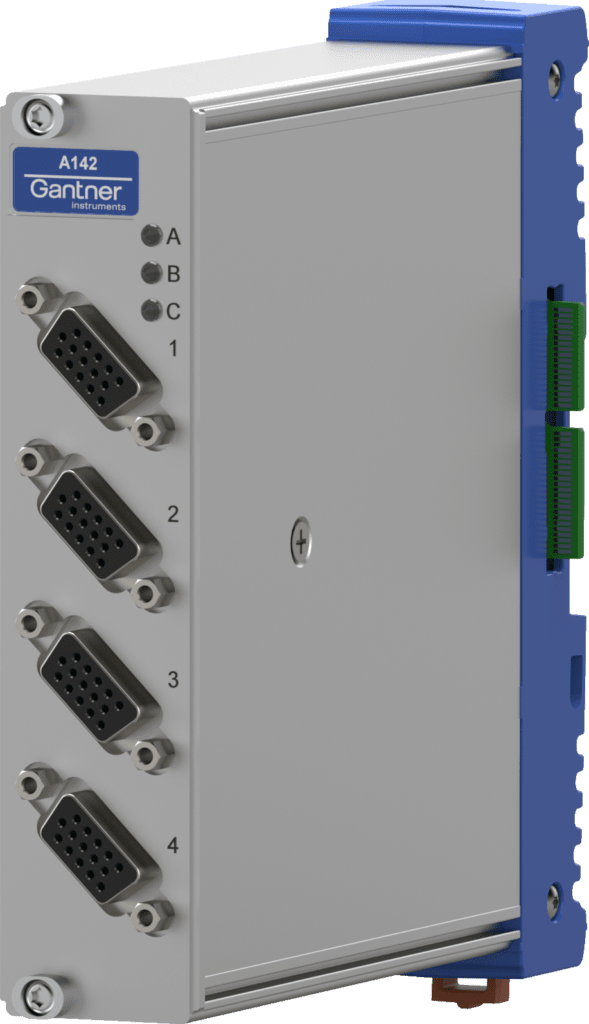

You can acquire data and control your testing operations with Q.series X systems. With the introduction of our new Q.series X A142, we have extended our capabilities for force and motion control applications. The Q.series X A142 is a universal input and output module designed with closed-loop control applications in the field of automotive, aerospace, and mechanical testing in mind. It features all sensor interfaces typically found on a hydraulic, pneumatic, or electric test actuator. By combining with an onboard 10 VDC analog output and test.con’s PID controller functionality, you can turn your Q.series X system into an integrated data acquisition and control solution for any force or motion control application.

The A142 comes with three 18-Bit, 20 kHz analog inputs (SAR ADC). You can use two inputs for LVDT/RVDT sensors or strain gage-based transducers, allowing you to use dual-bridge load cells for critical force control applications. The third analog input is a 10 VDC voltage input that can be freely configured for, for example, a potentiometric sensor or an external function generator as input for the PID controller. An additional Synchronous Serial Interface (SSI) makes the A142 unique. SSI is a point-to-point serial communication standard for digital data transmission between a master and a slave. SSI is commonly used with absolute encoders, as well as with Temposonics position sensors from MTS Sensors.

What is SAR ADC?

The method of Successive Approximation Register (SAR) is a method used in A/D converters for converting the analog signal into a digital signal. It is based on the comparison of the analog input voltage with a reference voltage. In successive approximation, the comparison is made step by step and is repeated continuously, whereby the reference voltage is changed so that it increasingly approaches the input voltage. Unlike a sigma-delta ADC, the SAR architecture does not have latency. The relatively high sample rate and zero-latency make the SAR ADC suitable for closed-loop control applications.

Key Features:

- 2 Analog inputs for strain gage transducers or LVDT/RVDT sensors

- 1 Synchronous Serial Interface (SSI)

- 1 10 VDC analog input

- 1 10 VDC analog output

- 4 Digital inputs and outputs

- 20 kHz update rate

- Low-latency 18-Bit SAR ADC

- 500 VDC galvanic isolation for all analog inputs

- Onboard virtual channels for scaling, filtering, and calculations

- Available in Q.bloxx X, Q.brixx X or Q.raxx X packaging

- Optionally as EtherCAT slave module (XE version)

- 15 Pin standard D-sub connectors

Read more about our Q.series X Data Acquisition System here.

More articles

The 35th Dresden Bridge Building Symposium 2026

Join us on March 18–19, 2026, in Dresden, Germany, for the 35th Dresden Bridge Construction Symposium (DBBS) - one of the most prestigious events in bridge engineering.

Read more...Turn your TwinCAT automation system into a high-performance Data Acquisition System

Connectivity and flexible integration of our high-accuracy and high-speed I/O modules into any automation system is in our DNA. That is why we have made our high-performance Q.series X I/O modules available for easy and comfortable integration into TwinCAT, the EtherCAT master from Beckhoff.

Read more...Test Measurement DAQ for SEDS sponsored by Gantner Instruments

Gantner Instruments, Inc. is proud to be a platinum sponsor of the SEDS-Students for the Exploration and Development of Space-organization at the University of California San Diego. Gantner Instruments provided the data acquisition system required for their Colossus Static Fire System Test Stand. This full test system is complete with Gantner’s Q.station PLC controller, precision DAQ modules for TC, Voltage, Current, Resistance and Pt100.

Read more...Experience a New Level of Possibilities With Our New Website!

We are thrilled to announce the launch of the new Gantner Instrumentswebsite and introduce you to a few of its features.Here’s a sneak peek of what you can expect to […]

Read more...