Key Challenges in Test Bench Development

- Navigating Compliance and Safety Standards

Test benches in regulated industries must adhere to rigorous standards such as CE marking and EU conformity directives. Achieving compliance requires meticulous attention to detail and can become a complex, time-consuming task without the right tools to manage and document regulatory requirements throughout the development process. - Managing System Complexity and Risk

Test benches often involve monitoring industrial devices or simulating critical operations, introducing significant operational risks. Inadequate risk management can lead to equipment failure, safety hazards, and inaccurate test results. Integrating robust risk management strategies from the outset is crucial to ensure system reliability and operator safety. - Ensuring Seamless System Integration

Integrating various hardware and software components can present many challenges, especially when multiple devices need to operate synchronously. Effective system integration simplifies maintenance, ensures accurate data acquisition, and facilitates rapid troubleshooting. Without seamless integration, system performance can suffer, and diagnosing issues becomes more difficult. - Documentation and Traceability

Proper documentation is not only required for compliance with regulatory standards, but ensures transparency and aids in future maintenance. However, tracking every component and process can be overwhelming without efficient tools to support documentation and traceability.

How test.con Addresses These Challenges

Streamlined Graphical Programming for Real-Time Applications

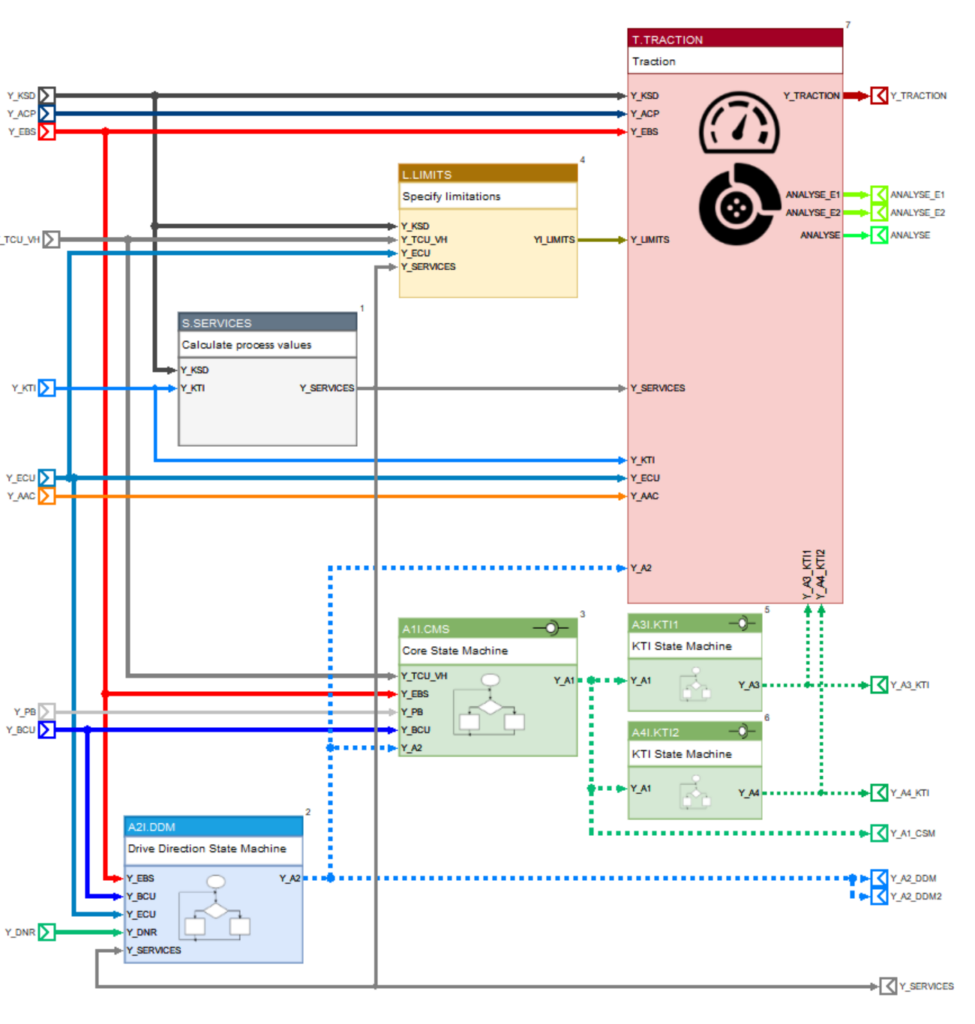

test.con offers intuitive, drag-and-drop graphical programming for Gantner’s Q.series X controllers, eliminating the need for traditional coding. Users can efficiently design custom logic, data processing algorithms, and visualization functions. This approach accelerates development and makes programming accessible to engineers who may not have extensive software development experience.

Powerful Risk and Compliance Management

With its model-based development approach, test.con allows for the integration of complex control logic and safety functions at every stage. Regulatory requirements can be managed within the software, enabling the incorporation of industry standards and the documentation necessary for CE certification. test.con also supports programmable automation controller (PAC) functionality, providing the flexibility to meet specific safety and regulatory demands across different industries.

Integrated System Architecture and HMI Design

test.con has the ability to design human-machine interfaces (HMIs) directly within the platform. This capability enables operators to visualize and control the entire system in real-time, adding critical layers of monitoring and control for risk mitigation and seamless system integration. By unifying system architecture and HMI development, test.con enhances operational efficiency and reduces complexity.

Built-In Documentation and Traceability

test.con integrates documentation and traceability into the development process. From initial requirements analysis to final testing, the software supports comprehensive tracking of every element within the project, from individual components to complete system architectures. This integrated documentation facilitates CE compliance and provides a complete system record for future maintenance and audits.

Partner with Gantner Instruments for Effective Test Bench Solutions

Whether you’re developing a complex test bench or seeking support for regulatory compliance and risk management, Gantner Instruments, in partnership with ProSign, offers the expertise and technology to assist you. test.con provides a comprehensive solution for building reliable, compliant, and efficient test benches tailored to your specific project needs.

Get Started with test.con

Ready to overcome the challenges of test bench development? Contact our team for a consultation, and we’ll guide you in implementing a solution that meets the highest industry standards.

Learn more about test.con and enhance your test bench development today.

Want to see a hands-on example?

This video guides you through all the required steps, including system design, modeling, and creating a curve generator.

More articles

Gantner Instruments presents new Machine Learning and Fault detection routines at leading PV and Energy conference in Brussels, Belgium

Within the EU founded project “IPERMON” (“Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity”) Gantner Instruments was developing different fault detection routines and failure classification methods for time series data sets.

Read more...Hydrogen Future Conference

The Regional Hydrogen Future Conference will take place on 11 February 2026 in Augsburg and is organized by IHK Schwaben. The conference focuses on green hydrogen as a key driver for sustainable value creation resilient energy systems and climate friendly mobility. The event brings together experts from business politics and science and offers space for exchange networking and new ideas around the hydrogen economy.

Read more...Integrate Gantner Instruments with NI LabVIEW

The easiest way to connect Gantner DAQ to your LabVIEW environment—now better than ever. Gantner Instruments understands the needs of engineers working across R&D, testing, and industrial automation. That’s why we’ve made it easier than ever to connect our modular, high-precision data acquisition systems, Q.series and Q.series X, with one of the most widely used engineering platforms: NI LabVIEW.

Read more...Gantner Instruments TechDay

On April 28, 2026, Gantner Instruments invites you to the GI TechDay DACH 2026 at their headquarters in Schruns, Austria. Join this free event focused on testing and inspecting electric drives, batteries, and fuel cells.

Read more...