That combination is one reason SHM is moving from “interesting pilot” to “must-have measurement infrastructure” in 2026: owners and engineering teams need traceable, defensible data that can support decisions on load rating, maintenance prioritization, retrofit timing, and post-event assessment. The scale is not small; U.S. bridge inventory is measured in the hundreds of thousands.

A useful reference point: U.S. bridge condition summaries from the National Bridge Inventory (NBI) indicate tens of thousands of bridges in poor condition (often described as “structurally deficient”), which puts pressure on agencies and their contractors to improve how structural decisions are justified.

Why focus on the U.S.? Three practical realities shape SHM decisions

- Scale of inventory and condition pressure: The U.S. bridge inventory is immense, and public reporting keeps the condition visible.

- Compliance and defensibility culture: Inspection and reporting frameworks such as NBIS shape how decisions are justified and documented.

- Funding + programs pushing modernization: Industry tracking (e.g., ARTBA’s bridge reporting tied to NBI data) highlights how federal/state programs are pushing repairs and better asset strategies; SHM fits where it can reduce uncertainty and prioritize interventions.

The bottom line: in the U.S., SHM is increasingly evaluated on whether it produces auditable data that changes decisions, not just interesting plots.

What Modern SHM really needs from the measurement side

A modern SHM system is not a box of sensors plus a logger. It’s a reliable measurement system that must remain trustworthy while continuously monitoring assets for extended periods (at least 10+ years), regardless of whether staff changes, models evolve, and major events occur.

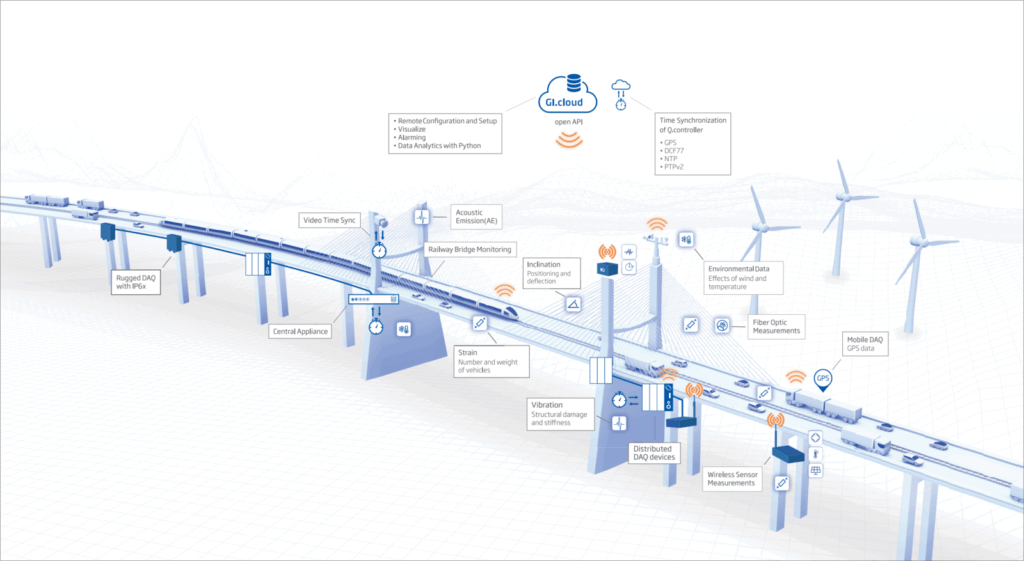

A Typical U.S. SHM deployment combines:

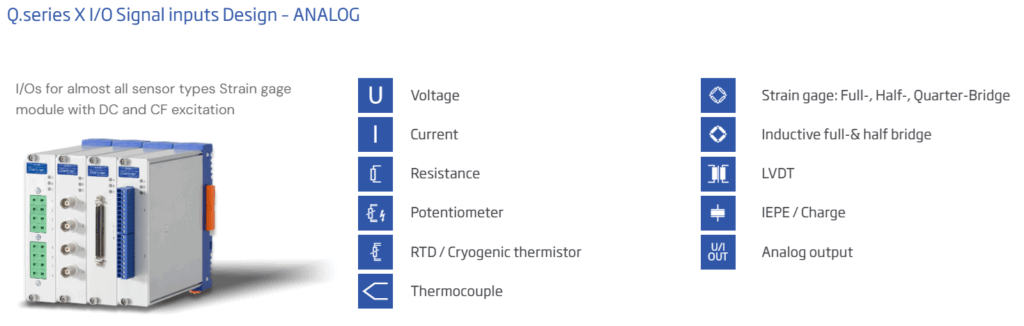

- Strain (foil strain gauges, vibrating wire, bridge/quarter-bridge)

- Acceleration / vibration (IEPE accelerometers, MEMS where appropriate)

- Displacement / tilt / crack (LVDT, string pots, inclinometers, crack meters)

- Temperature + environment (RTD/thermocouple, humidity, wind, water level, etc.)

To stay valuable over the years, these signals must be:

- Accurate and stable across temperature cycles and field conditions

- Time-aligned across the entire structure (and across distributed locations)

- Logged with metadata so data is reusable for future load rating, model updates, and audits

If any one of these collapses, drifting zeros, mixed clocks, or undocumented scaling, confidence in the entire SHM program erodes.

The hidden killer in SHM: time alignment

Many SHM systems “fail quietly,” not because sensors die, but because clocks drift.

If strain, displacement, and acceleration are sampled at different time scales, the errors appear exactly where U.S. teams need the data most: when correlating events and extracting dynamics. Mode shapes smear, cause-and-effect blurs, and the output becomes hard to defend.

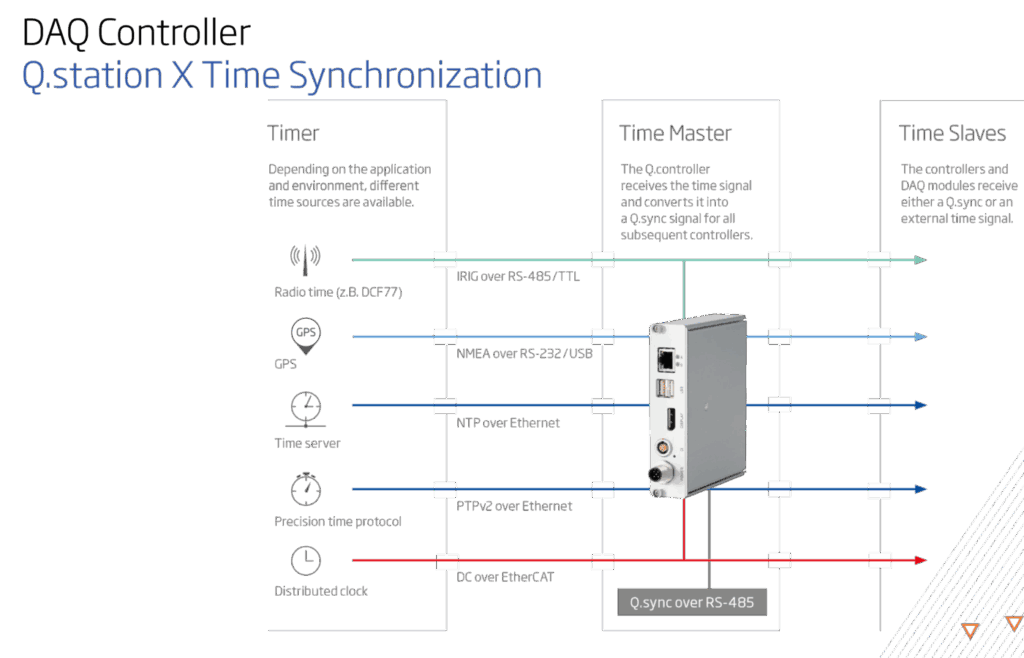

That’s why synchronization has become a core requirement in distributed monitoring systems: PTP (IEEE 1588) and GPS-referenced time are widely used to keep distributed nodes aligned, often achieving sub-microsecond timing accuracy in suitable architectures.

For U.S. infrastructure workflows, this matters because teams increasingly tie measurements to:

- controlled truck passages / WIM events

- wind gust and vibration response

- seismic triggers

- post-impact inspections (ship strike, vehicle impact)

- “before/after” baselines around maintenance

Without reliable timestamps and time alignment, you lose the ability to prove correlation.

A modern SHM architecture pattern

The strongest pattern we see in 2026 is distributed measurement:

- Place measurement modules close to sensors (short analog runs, less noise pickup)

- Synchronize the distributed nodes to a common time base

- Log locally for resilience, then publish upstream as needed

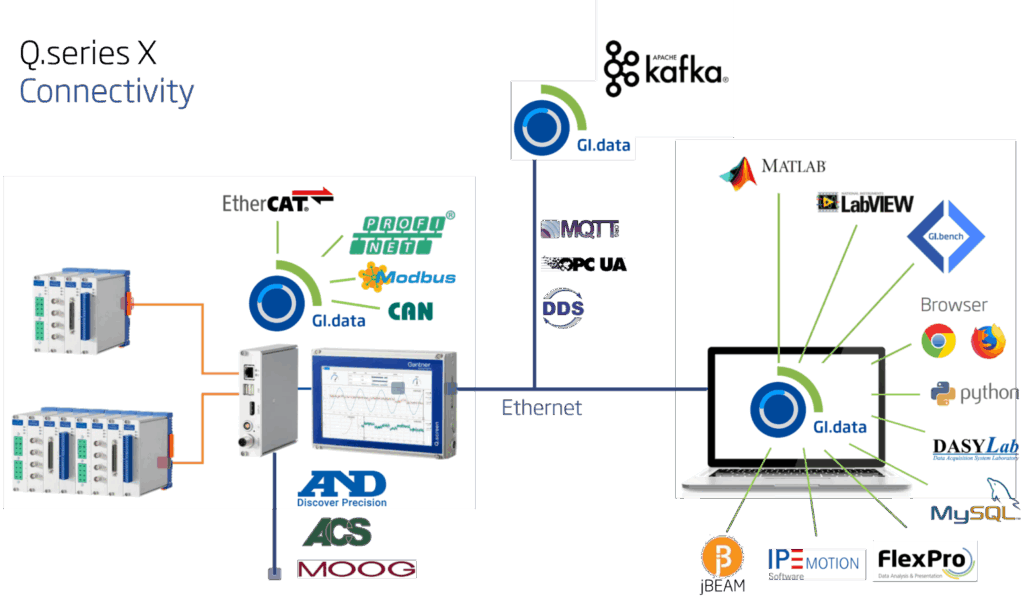

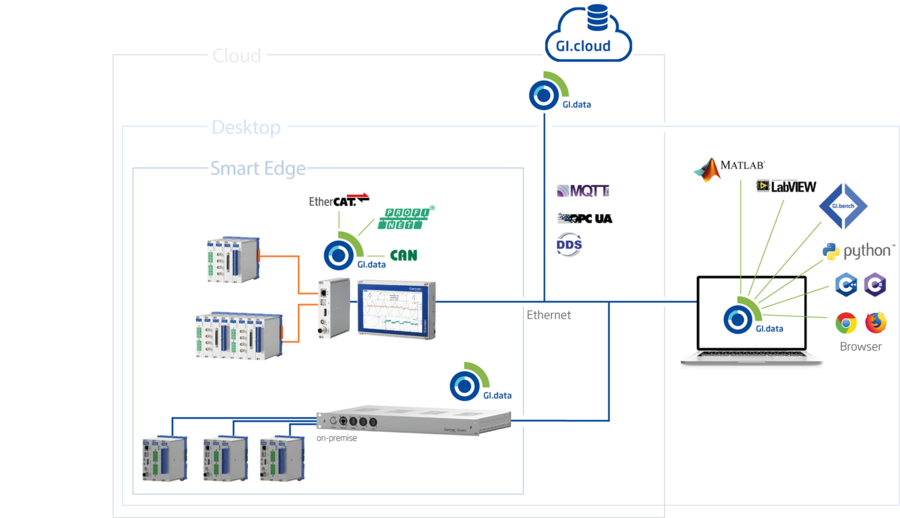

This is where modular DAQ platforms, such as Gantner Instruments’ Q.series X, naturally align with SHM requirements. In practice, the idea is:

- Q.series X I/O near the structure for stable, high-resolution sensor acquisition

- Q.series X controller / edge device for logging + health status + event handling

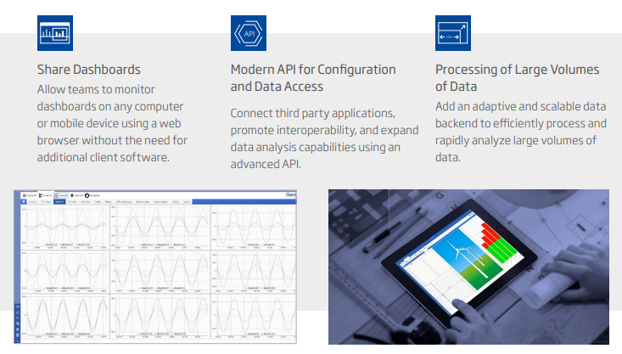

- GI.bench or GI.cloud as the engineering environment for configuration, visualization, and operational dashboards

- Open paths to downstream analysis (FE models, Python/MATLAB tooling, cloud pipelines) through standard integration options

The goal is simple: keep the physics clean at the edge, keep the timestamps defensible, and make the data usable for multiple stakeholders.

Long-term stability is not optional

In U.S. bridge and tunnel monitoring, the hard part isn’t collecting data for a month; it’s keeping data trustworthy for years through:

- power dips, outages, and restarts

- lightning / surge exposure and grounding realities

- condensation, corrosion, cabinet temperature swings

- sensor drift and recalibration cycles

- communications interruptions (cellular dead spots, tunnel networks, remote sites)

Field programs also face lifecycle reality: the system you install today will outlive the original project team. That’s why modular systems that preserve configuration and support module replacement without “reinventing the system” tend to win in the long term.

A useful frame from the U.S. Federal Highway Administration’s research perspective is that long-term monitoring is motivated by the reality that a significant share of U.S. bridges have exceeded nominal design-life assumptions.

From measurements to models and digital twins

U.S. owners and engineering consultants increasingly want SHM to feed decisions, not just dashboards. That typically means:

- trending for creep, thermal behavior, settlement, and degradation

- event capture for storms/seismic/overloads

- dynamic response and modal parameters for stiffness change detection

- model updating and comparison against FE expectations

The enabling factor is a clean, synchronized, well-documented measurement pipeline that downstream tools can trust.

This is where open connectivity matters: when measurement systems expose data through standard enterprise and industrial patterns, it becomes realistic to connect field data to:

- load rating workflows

- FE model updating / calibration

- asset management databases

- cloud analytics (where appropriate)

Choosing the best technology that can grow with the structure

At the start of an SHM program, the best questions to ask are:

- How do we guarantee synchronization and traceability for at least 10 years?

- How will future teams interpret today’s scaling and metadata?

- How do we add sensors later without replacing the system?

- How do we handle events, outages, and maintenance without data loss?

If SHM is treated as critical measurement infrastructure, modular, distributed DAQ platforms, paired with an engineering environment such as GI.bench or GI.cloud,provide owners and consultants a realistic path to long-term, defensible monitoring.

If you’re planning a U.S. SHM program for bridges, tunnels, dams, or industrial structures, Gantner Instruments can help you determine a scalable SHM system architecture that is both accurate and reliable for the long haul.

More articles

Q.series X A101 SV: Universal Measurement Module with Sensor Supply

The Q.series X A101 2 x DB15HD SV module from Gantner Instruments is a precisely engineered multi-functional measurement module that seamlessly integrates into a variety of industrial applications. With 2 universal analog inputs and a programmable sensor supply voltage and current limit, this module is crafted to provide precise and reliable data across a spectrum of measurement needs.

Read more...Apprenticeship at Gantner Instruments

We open our doors to exclusive insights into our company by talking to our apprentice, Philip, about his experiences with his apprenticeship at Gantner Instruments. In this interview, Philip tells us his story, from his search for an apprenticeship to his everyday life with us, and provides a deeper insight into a corporate culture that is much more than just a workplace.

Read more...Precise Temperature Measurement with Pt100

Temperature measurement is one of our key competence areas. Here we maintain a position of global leadership. Our advanced 4-channel Q.bloxx A105 measurement module sets new standards in terms of stability and precision. For many different applications, the extremely precise and stable measurement of temperatures is an absolute prerequisite for the control of processes or the success of product innovations. In addition to the essential precision, particularly important aspects of this are the maintenance of stability when changes occur in the ambient temperature and ensuring long-term stability.

Read more...GI.basic Training in NRW

GI.basic training near you: we will be in NRW on May 16, 2024

Read more...