We want to give you a look behind the scenes at Gantner Instruments and get to know the many facets of our company. Learn first-hand how we design test and measurement technology, and promote and develop the careers of young talents like Philip. Experience an atmosphere characterized by innovation, collaboration, and the celebration of individual potential.

Here at Gantner Instruments, it’s not just about technology – it’s a community where creative thinking, lifelong learning, and personal growth take center stage. Our company culture creates space for ideas and innovation, allowing our employees to reach their full potential and achieve their professional goals.

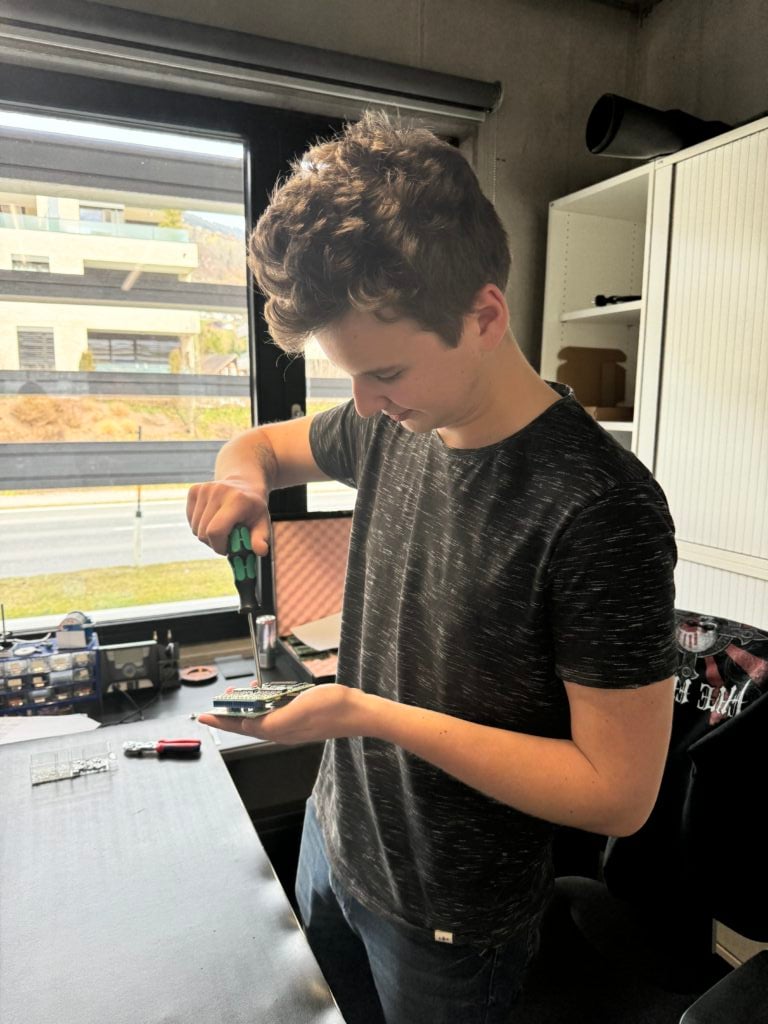

Philip, tell us something about yourself!

I started with elementary school in Partenen, then went on to secondary school in Gortipohl. After that, I wasn’t sure whether I wanted to go to a secondary school like “HTL” or whether I wanted to go to the “Polytechnische Schule” after all. Ultimately, I opted for the “Polytechnische Schule,” although I was in a completely different field there, in tourism. There, I realized that tourism wasn’t for me after all, and I tried the technical field. I got invited for a test workday at Gantner Instruments, and I liked it here the best. That’s why I applied for an apprenticeship as an electronics technician. I have been here since September 2020 and will take my final apprenticeship exam in March 2024.

Why did you decide to do an apprenticeship?

I wasn’t sure at first whether I wanted to go to school or do an apprenticeship. I decided to do an apprenticeship because it makes me more independent. I earn my own money and have more free time because I don’t have to study as much – those are my main reasons.

How did you find out about the electronics technician profession?

I’ve always been interested in working in the electrical sector, but initially, I was more interested in becoming an electrician. Through my brother, who was also at the “HTL”, I became interested in electronics, and after the test workday, it was clear to me that I wanted to do electronics.

What aspects of the electronics profession particularly appealed to you, and what tasks do you now carry out as an electronics technician at Gantner Instruments?

I was particularly interested in the precision work – soldering under the microscope, for example.

My main activities are commissioning, assembling, loading, and configuring measurement modules, and a lot of soldering.

What further and advanced training opportunities were made available to you?

I would have had the opportunity to do my A-Levels in combination with the apprenticeship, but I decided against it because I don’t intend to go to university after completing my apprenticeship, so I don’t need my A-Levels.

How is the support from experienced colleagues and supervisors during your apprenticeship?

The level of support is very high – if I have any questions, everyone is willing to help me. And if I have any other questions at school, for example, I can always ask my colleagues, and they will help me.

Were there any special training courses or workshops that helped you?

So far, I have attended a training course or workshop at WIFI every year. However, it was only sometimes directly related to my work here. It was more general training that the company also paid for.

Which moments during your apprenticeship at Gantner Instruments stand out for you?

The highlights were the jobs where you don’t work alone but with the whole team – teamwork stands out for me. I always particularly enjoy it when we have larger jobs that we can work on together.

How do you see your future after completing your apprenticeship?

After completing my apprenticeship, I will first join the army in June and return to Gantner Instruments in December.

Philip’s story appeals to young talents looking for an apprenticeship and anyone interested in an exciting and dynamic career in test and measurement. At Gantner Instruments, we see ourselves as guides for future talents and are proud to shape individual careers through tailored support and encouragement.

Our company culture is focused on seeing people like Philip not just as apprentices but as essential members of a team that is helping to shape the future of this fascinating industry. We firmly believe that every individual joining our community can contribute uniquely. If you desire to find not just a job but a professional passion that drives you, we warmly invite you to apply to join us.

Intersted? Great!

We are always looking for experienced individuals to join our team, and we invite you to apply if you believe you could be a great fit.

Has Philip’s story inspired you? Are you looking for an apprenticeship as an electronics technician? Then, please send us your complete application documents. Our apprentice trainer, Marco Berginz, looks forward to receiving your documents and will arrange a trial appointment with you.

More articles

Wendelstein 7-X Stellarator

After 9 years in construction, the stellarator (nuclear-fusion machine) of the Max Planck Institute in Greifswald generated plasma for the first time on December 10, 2015. The reactor had been gradually ramped up over the past 12 months. The event was given extensive coverage in the media. Gantner Instruments specially developed sensors for temperature and strain measurement for the project, which are otherwise unavailable on the market.

Read more...Measure the evolution of battery technology

New ground-breaking products and powerful solutions for fast and accurate Cell, Module and Pack testing

Read more...Standalone E-drive testing in 3 simple steps

Automobiles have a variety of electrically operated drives. Be it the sunroof, the window lifter, the seat adjustment or the trunk lid, everywhere you look, you’ll find electric motors that provide us comfort in our cars.

Read more...Daily Meals for 300 Children

After establishing our company last year in India, we became aware of the Sri Karpagavalli Vidyalays Middle School, a school for 300 girls and boys ages 5 through 14. Not only do these children, coming primarily from the slums, lack educational material, they frequently do not even have elementary necessities like food.

Read more...