Mobility

Gantner Instruments is well-suited for mobility engineering applications, providing specialized equipment and tools for ensuring vehicle and components’ safety, reliability, and performance. Our products can effectively and accurately perform durability, road, climate, vibration, and endurance tests, providing valuable data for vehicle design and performance improvement. We offer flexible, easy-to-use, and customizable solutions to meet the specific testing needs of our customers.

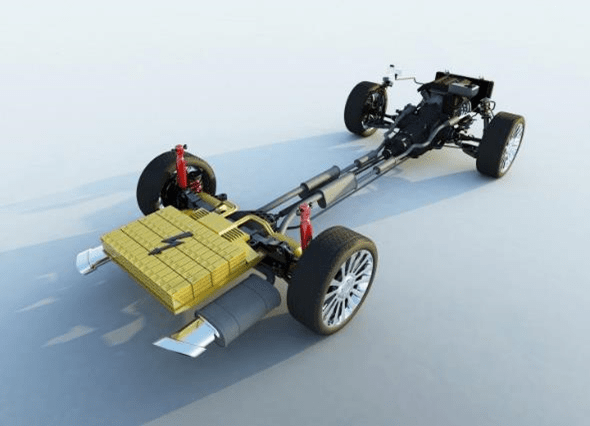

Electric Vehicle and Battery Testing

Electric vehicle testing simulates different driving conditions and loads to evaluate the performance of the electric motor (such as torque, speed, power, and efficiency), the inverter (such as voltage and current handling capability), and the transmission (such as gear shifting and overall efficiency). Battery testing evaluates the battery pack’s performance (such as capacity, power output, energy efficiency, and overall durability) using specialized battery testing systems, which can simulate different charging and discharge cycles, temperatures, and other conditions.

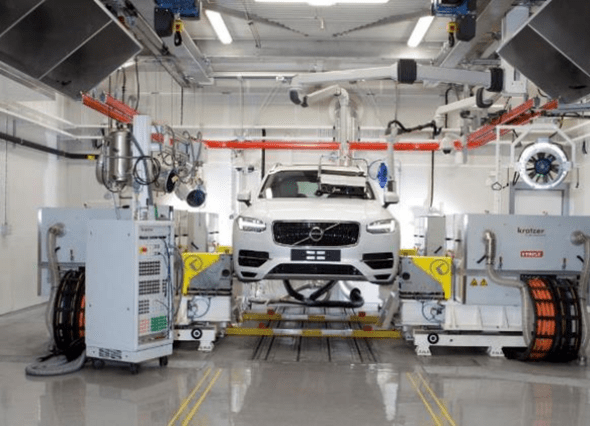

Engine and Powertrain Testing

ICE testing includes bench testing (engine test stand to measure performance under different operating conditions), emission testing (measuring engine emissions, to ensure compliance with regulations), and durability testing (running the engine for extended periods of time to evaluate its durability under different conditions. Powertrain testing includes chassis dynamometer testing (simulating vehicle’s road load under various driving conditions), transmission testing (evaluating efficiency, durability, and performance under different loads and operating conditions), and drivetrain testing (evaluating performance of the drivetrain components, such as the drive shafts, axles, and differential).

Durability Testing

Evaluating the performance of a vehicle or its components over an extended period of time, under a wide range of operating conditions, to determine its reliability and expected service life, identify potential problems early on, before they can cause serious damage or failure, and to ensure that the vehicle or component meets design specifications and safety standards. Examples include: Road testing, climate testing, vibration testing, endurance testing, HALT (Highly Accelerated Life Testing), and HASS (Highly Accelerated Stress Screening).

People Mover Monitoring

Allows for the evaluation of how people interact with the environment and how the environment affects their movement. It also helps identify areas that can be improved for better mobility, such as reducing congestion or improving safety. People Mover Monitoring is also used to track the performance of transportation systems, such as buses, trains, and other forms of public transportation. This data can be used to identify areas for improvement, such as increasing the efficiency of the system or reducing the time it takes for travelers to reach their destination.

Railway Monitoring

Railway monitoring is a process used in mobility testing to measure and record data from railway tracks and related infrastructure. Specialized measurement instruments allow for precise data collection and analysis of data to monitor vibration, displacement and load, and stress, providing accurate measurements for bridges and other infrastructure. Railway monitoring can also be used to test the integrity of railway platforms and components, ensuring they can withstand the forces and loads they will experience. This ensures railway systems are safe and reliable.

Why Gantner Instruments

Flexible Mixed-Signal Data Acquisition

Q.series X is a mixed-signal, multi-channel data acquisition solution offering a versatile range of I/O modules. You can measure voltage, current, temperature, torque, strain, vibration, counters, and more. With this maximum sensor flexibility, the DAQ system can be easily adapted to the demanding requirements of EV powertrain testing.

Minimal Signal-to-Noise Ratio

All Q.series measurement modules come with 1500 VDC channel-to-channel, channel-to-supply, and channel-to-bus galvanic isolation. In addition, each module comes with pre-engineered conditioning functions like linearization and filtering. The modules are capable of sample rates up to 100 kHz, with each channel having its own 24-bit ADC.

Fully Configurable Data Loggers

Engine testing generates a lot of data with varying sample rates. Mixed-signal, multi-frequency data logging ensures only the data you need is saved, avoiding unnecessary data storage overhead.

Easy Integration

Easy-to-use APIs, modern publish-subscribe protocols, and various Fieldbus interfaces, like CAN, EtherCAT, and PROFINET, make it simple and easy to integrate Q.series X into any supervisory control and data acquisition system. Plugins & drivers for LabVIEW, MATLAB, and Python, among others, enable advanced data analysis and reporting.

1500V High-Voltage Galvanic Isolation

Q.series X high-voltage isolation measurement modules are suitable for voltage, current, RTD, thermocouple, IEPE, and strain gage sensors sampling up to 100 kHz. All high-voltage isolation modules include a minimum of 1500 VDC channel-to-channel, channel-to-supply, and channel-to-bus galvanic isolation.

What our clients say

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.