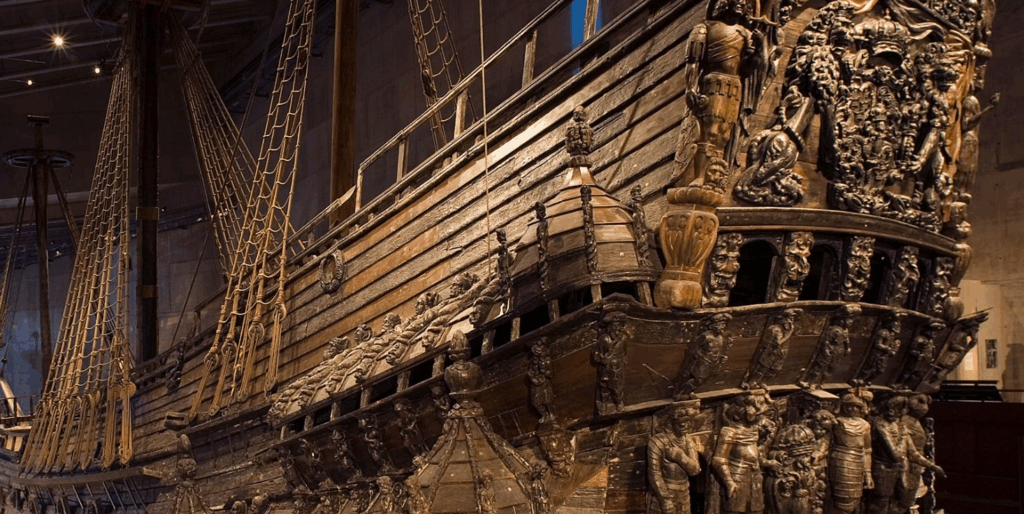

The Core Challenge: A 400-Year-Old Ship Without Buoyancy

Today’s engineering challenge is clear but severe: the ship now stands on land, and buoyancy no longer supports her weight. The PEG-treated, 400-year-old hull transfers gravity through discrete contact points, and conservators have measured slow but significant deformation.

This situation gives rise to a number of significant issues:

- Uncertain load paths and hidden overloads at individual support points

- Progressive deformation over years that can go unnoticed in daily operation

- High risk and cost of structural interventions on an irreplaceable heritage asset

- Need for decisions based on assumptions rather than data

To address this, the museum is replacing the old cradle with an adjustable steel support system instrumented with a Gantner Instruments real-time force-monitoring solution. The goal is to keep the hull shape stable for many years and to fix harmful loads before they cause damage, not just during installation, but continuously as the ship, the building, and the climate change over time.

Why the Old Cradle Had to Go

The display cradle installed after salvage made public exhibition possible. However, decades of measurements showed non-uniform reactions at the contact points and a gradual lean to port side. In simple terms, the passive mechanical cradle had reached its limits as a safe, long-term support for the ship.

Key issues with the old solution:

- No active way to balance loads over time

- No direct measurement of forces at each support point

- Only periodic inspections, with the risk that damaging trends remain invisible between campaigns

To solve this, the museum chose an adjustable steel cradle that can be re-tuned over time and combined it with Gantner Instruments’ real-time force-monitoring system. Gantner’s technology directly targets the pain point of “blind” structural support by turning each contact point into a measurable, controllable variable.

Instead of assuming that forces stay where the design model predicts, the team can now measure, verify, and correct them using live data.

The New Support: Adjustable Steel Cradles and an Internal Skeleton

The museum is installing a series of engineered steel cradles that follow the shape of the hull and connect to a new joint beneath the keel. Each cradle is contoured and mechanically adjustable, so the loads at each contact point can be tuned after installation and re-adjusted as needed in the future.

An internal steel skeleton will link frames and deck structures. This increases the overall stiffness and makes the load path from deck to keel more predictable.

The work is staged to reduce risk to the ship. The team adjusts one area, checks the reaction forces in real time, and then moves on to the next. Installation began in 2024 and is planned to achieve full external and internal stabilization by the end of the decade.

The measurement system must address a different set of issues because the construction and monitoring phases take place over a number of years.

- Long-term stability of measurements across seasons and decades

- Ease of maintenance in a public museum environment

- Consistency of data across generations of staff and evolving conservation strategies

Gantner’s modular data acquisition platform and time-synchronized architecture are designed to meet exactly these constraints.

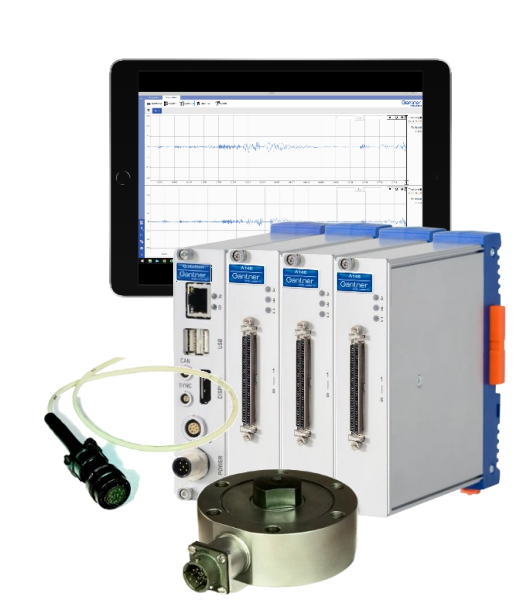

Turning Structure into Data: 182 Load Cells and Synchronized DAQ

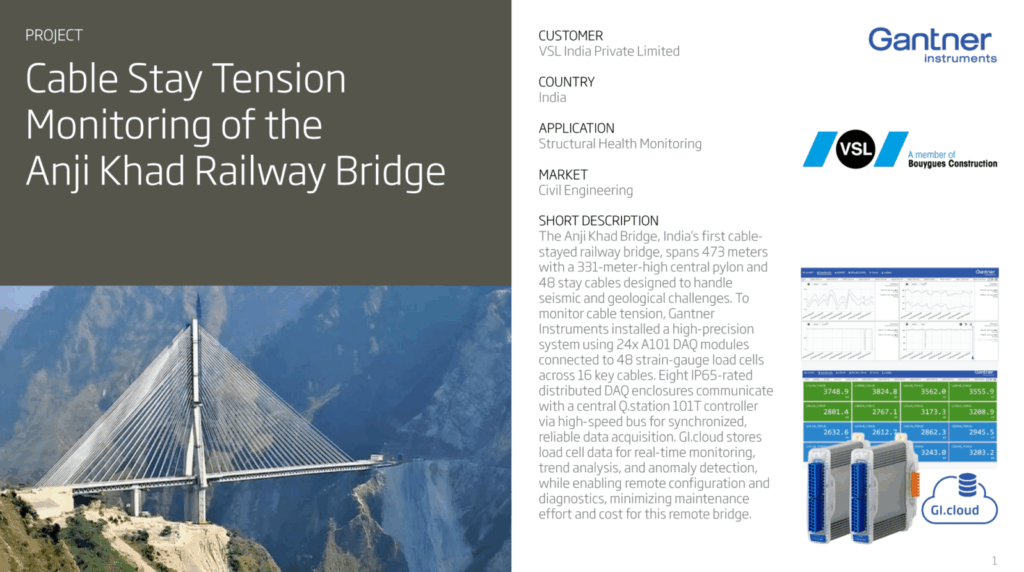

A network of 182 load cells turns the new support into a structural health monitoring (SHM) system. Each instrumented interface measures the actual force at that point, so the whole cradle behaves like a tunable mechanism instead of a fixed steel construction.

This directly mitigates the pain point of not knowing where loads really are. Instead of relying on simplified models and infrequent surveys, conservators now have:

- Real-time force values at each support point

- Immediate feedback when adjustments are made

- A continuous record of how the ship’s load distribution evolves over time

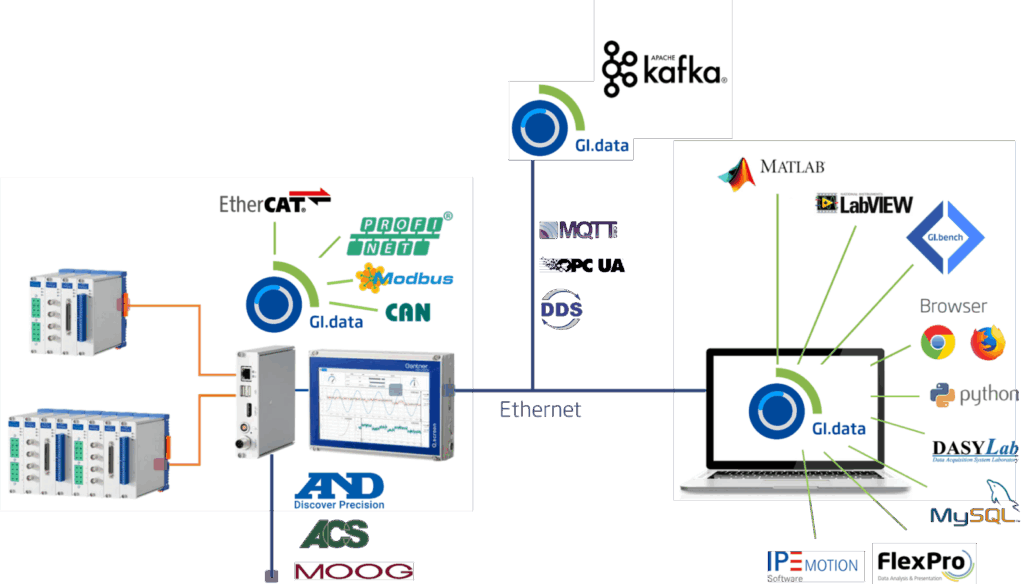

Distributed measurement modules with electrically isolated bridge inputs are installed close to the load cells. This keeps signals stable, reduces noise from long cable runs in the public gallery, and preserves measurement accuracy. Synchronized sampling ensures that force data from all support points is collected at the same time. This is crucial when you want to compare changes across the ship, track slow trends over years, and prove that a correction at one cradle does not create a new problem somewhere else.

Data acquisition is handled by Q.bloxx XL A116 modules and a Q.station XB controller. GI.bench is used to configure channels, log high-resolution data, and visualize results. This combination is built for long use. It provides precise, evenly spaced sampling, reliable time synchronization, and repeatable measurements. These features are essential for comparing data over many years and preventing data drift that could affect conservation decisions.

From Data to a Live Structural Model: 3D Load Maps and Digital Twin Behavior

Another major pain point in long-term conservation projects is the gap between models and reality. Structural analyses are often based on initial assumptions that are never fully validated in operation.

In the Vasa project, real-time force channels flow into a browser-based dashboard where conservators and engineers see live values, trend lines, and a three-dimensional map of loads on the hull and support. This 3D view behaves like an operational digital twin: it links each measurement channel to a position on the ship and shows how the load pattern changes when the team adjusts a cradle, replaces a fastener, or responds to long-term deformation.

Alarm thresholds make the system proactive. If a cradle moves outside its allowed force range, staff receive a clear alarm, adjust the settings, and immediately see the updated load distribution on screen, often from a tablet in the gallery without touching the ship. This addresses the pain point of reacting too late to critical load shifts.

The same data also updates the structural model that engineers use for planning. Over time, this creates a feedback loop between model and reality: the digital representation of Vasa is continuously calibrated with real measurements instead of assumptions. This reduces uncertainty, lowers risk, and improves future decisions.

Without clear visualization and explicit alarms, critical load shifts go unnoticed and teams react too late.

Conservation Context: Chemistry, Climate, and Fasteners

The structural work is part of a wider conservation strategy. After salvage in 1961, Vasa was impregnated with PEG and dried under controlled conditions to stabilize the waterlogged oak. Today, the museum maintains tight temperature and relative humidity limits to reduce dimensional changes in the wood.

A long-term program has also replaced corroding mild-steel bolts to remove iron sources and improve the mechanical behavior of the hull.

Gantner’s system also addresses the issue of whether these diverse conservation measures work together as intended. The new adjustable steel support and internal skeleton work together with materials science and climate control. Engineering controls the forces and geometry acting on the structure; conservation science slows chemical and physical decay.

The DAQ system provides the long-term measurement backbone that links both worlds and shows whether the combined strategy is delivering the expected structural stability.

Roadmap and Replicabilit

As installation continues, the museum builds a long, continuous record of how the ship behaves: how loads shift over seasons, how maintenance actions change the force distribution, and how stable the global geometry remains over time. The aim is a stable, well-documented load path and a dataset that extends beyond the ship’s 400th anniversary and supports decisions for the next generation of conservators.

The challenges that Vasa faces are not unique.

- Complex structures with unknown real-world load paths

- Very long time horizons where trends matter more than single measurements

- Extremely limited tolerance for intervention or damage

Historic aircraft, timber roofs, monumental statues, and bridges all need ways to connect structural models with real loads and prove long-term stability.

The combination used here includes adjustable steel supports, load cell sensors, synchronized data collection, and browser based visualization that understands the model. Together, these elements provide a clear example of how occasional manual inspections can become continuous, data driven structural monitoring, reducing risk and uncertainty for heritage owners and operators.

Get detailed technical insight into how real-time data acquisition and visualization protect this asset.

Download this and more application examples now.

References and photo credit: Anneli Karlsson / Vasa Museum / Swedish National Maritime and Transport Museums (SMTM)

More articles

Trapped in Ice

Arctic ice is disappearing — the question is how fast. Summer sea ice could endure 100 more years, or it could vanish later this decade, with disastrous consequences for the rest of the planet. To nail down the answer, an expedition to the top of the world has to uncover the complex physics of ice.

Read more...Test Measurement DAQ for SEDS sponsored by Gantner Instruments

Gantner Instruments, Inc. is proud to be a platinum sponsor of the SEDS-Students for the Exploration and Development of Space-organization at the University of California San Diego. Gantner Instruments provided the data acquisition system required for their Colossus Static Fire System Test Stand. This full test system is complete with Gantner’s Q.station PLC controller, precision DAQ modules for TC, Voltage, Current, Resistance and Pt100.

Read more...Three steps to the Internet of Things (IoT) or: Where is analog big data derived from?

The break-up into the new era of Internet of Things (IoT), industry 4.0 or cloud computing takes an impressive pace and is also in several industrial applications irresistible. The industry with its huge amount of machines and components of divers size, value and function is faced by one big challenge: data from all these assets needs to be gathered and analyzed.

Read more...Fuel Cells: Advanced Measurement Techniques and Navigating the Hydrogen Market

The energy landscape is in a state of flux, shifting towards sustainable practices, and fuel cells have risen as a promising beacon of renewable energy. The mastery of fuel cells, their inner workings, and the nuances of their measurement, is central to this paradigm shift towards green energy. These devices, which are essentially electrochemical cells that transform chemical energy into electricity, promise a more sustainable, carbon-neutral future, provided we can harness their full potential. This blog post delves into the captivating scientific universe of fuel cell measurement, elaborating on the methodologies, complexities, challenges, and breakthroughs that make fuel cell technology so intriguing.

Read more...