As the global battery industry pushes towards higher energy densities, faster charging rates, and stricter safety standards, accurate and reliable measurement becomes non-negotiable. With unmatched precision, scalability, and ease of integration, Gantner Instruments helps engineers and manufacturers accelerate development cycles, optimize system performance, and confidently validate battery technologies.

Precision Measurement Solutions to Accelerate Battery Innovation

Accurate High-Voltage Measurement at Scale

Modern battery packs and modules now regularly operate at voltages approaching or exceeding 1000 VDC. Standard measurement technologies often fail to deliver accurate readings due to ground loops, noise interference, and insufficient isolation, which can jeopardize test integrity and safety.

Cryogenic Measurement for Advanced Energy Storage Solutions

For emerging battery technologies and hydrogen storage systems that utilize extreme cryogenic environments, traditional temperature measurement equipment suffers from thermal drift and sensor self-heating, resulting in unreliable data.

The Q.series X A105 CR cryogenic measurement module provides specialized, ultra-precise temperature measurement capabilities optimized for extreme low-temperature conditions (approximately 20 K). Featuring an ultra-low excitation current to eliminate sensor self-heating and precise calibration capabilities for cryogenic sensors (RTDs, silicon diodes, Cernox®), our module ensures accurate monitoring crucial for hydrogen storage efficiency and battery technology research in challenging thermal environments.

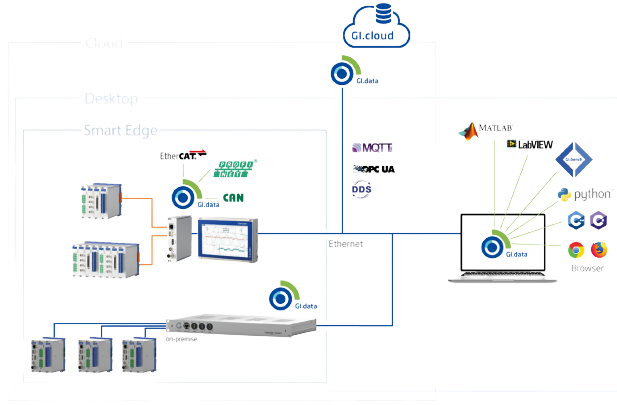

Seamless Integration and Future-Proof Flexibility

Unlike other platforms constrained by proprietary technology or limited compatibility, Gantner Instruments’ measurement solutions offer open interfaces (EtherCAT, CAN, Modbus, OPC UA, MQTT) for effortless integration into any existing test environment or industrial automation setup.

Our intuitive and OS-independent software tools support real-time data visualization, sophisticated analytics, and powerful data archiving with intelligent compression algorithms, simplifying the transition from development labs to production lines.

Why Visit Gantner Instruments at CIBF 2025?

CIBF2025 is your opportunity to see firsthand how Gantner’s measurement solutions translate into tangible advantages—faster development cycles, more reliable battery designs, and increased operational efficiencies. Our team at Booth 10B195 is ready to demonstrate these capabilities, discuss your specific testing requirements, and show you why leading battery manufacturers worldwide trust Gantner Instruments for precision data acquisition.

Schedule a one-on-one consultation or technical demonstration with our battery measurement experts at CIBF 2025, Booth 10B195. Discover how our precision data acquisition solutions deliver real-time insights, improved reliability, and unmatched integration flexibility, tailored specifically for your battery R&D and production challenges.

Contact for Appointments: David Tian (+86-13801225943 or WeChat)

More articles

Measurements at -40°C ambient temperature

We just tested our Q.bloxx XL A104 TCK in the climate chamber at -40°C ambient temperature and it does a perfect job under these extreme conditions.

Read more...Airbus has selected the Q.raxx EC with EtherCAT interface as the integrated control and measurement solution for their component structural testing lab

Airbus Helicopters is a world-leading designer and manufacturer of helicopters. The company’s product line offers the full spectrum of rotary-wing aircraft solutions for civil, government, military, law enforcement and parapublic uses. With the growth in business and innovation of their product offering, Airbus Helicopters decided to modernize their structural test facility at their main facility in Donauwörth, Germany.

Read more...Strain Measurements on Flexible Pipeline Systems

NOV in Denmark tests flexible pipeline systems with the Gantner Instruments Q.bloxx modules.

Read more...“Lunch and Learn” at EDF

In a very good atmosphere 18 specialists of EDF Energy Generation in Gloucester/UK listen the presentations from engineers of Gantner Instruments at the Lunch and Learn Meeting and enjoy sandwiches, chips, cookies and soft drinks as well as coffee and tea.

Read more...